10S Polishing Wheel for glass

Features

1. Abrasive materials: 10S polishing wheels are usually made of fine-grained abrasive materials, such as cerium oxide or similar compounds, which can effectively achieve high-quality polishing results on glass surfaces.

2. Smooth Polishing: The wheels are designed to provide a smooth, even polishing action, resulting in a smooth, blemish-free glass surface.

3.The 10S polishing wheel is suitable for various types of glass, including architectural glass, mirrors and decorative glass, making it a versatile tool for glass processing and manufacturing.

4. These grinding wheels are engineered to provide precise and consistent polishing, resulting in the desired surface smoothness and clarity.

5. 10S polishing wheels are known for their durability and long life, providing a cost-effective solution for glass polishing operations.

6. The design of the polishing wheel minimizes heat generation during the polishing process, reducing the risk of thermal damage to the glass.

7. Clean polishing: The 10S polishing wheel produces a clean, high-quality finish on the glass surface, minimizing the occurrence of scratches or defects.

Overall, the 10S polishing wheels offer smooth polishing, compatibility, accuracy, long life, and reduced heat generation, making them ideal for achieving high-quality polished surfaces on various types of glass.

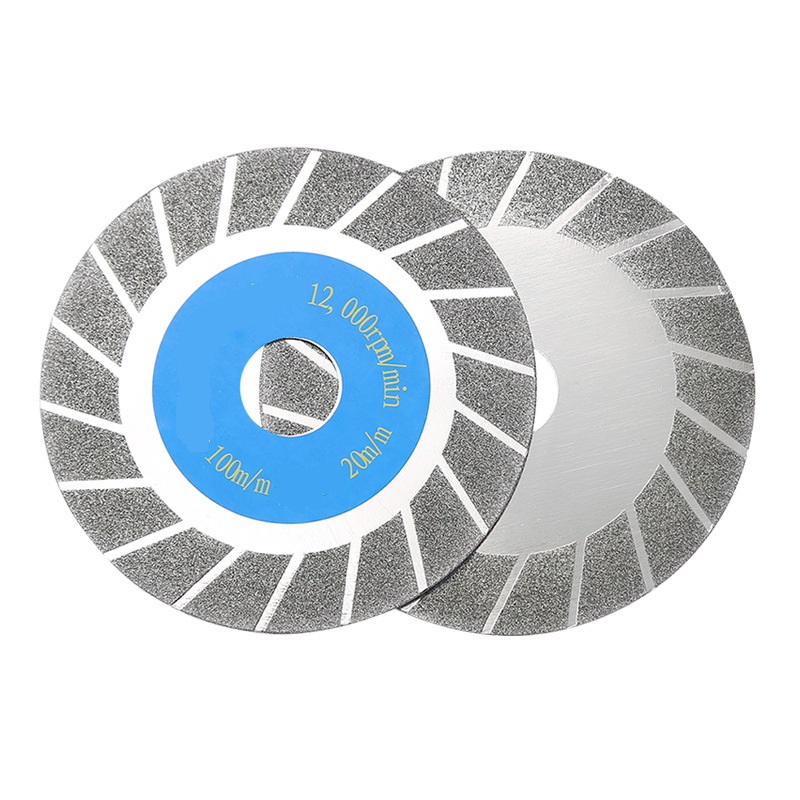

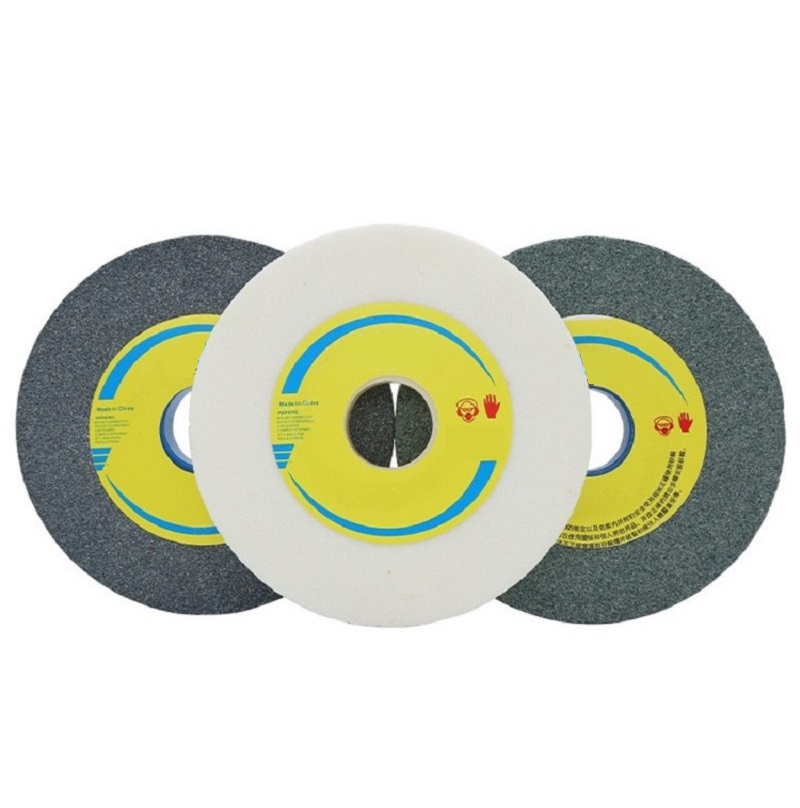

PRODUCT show

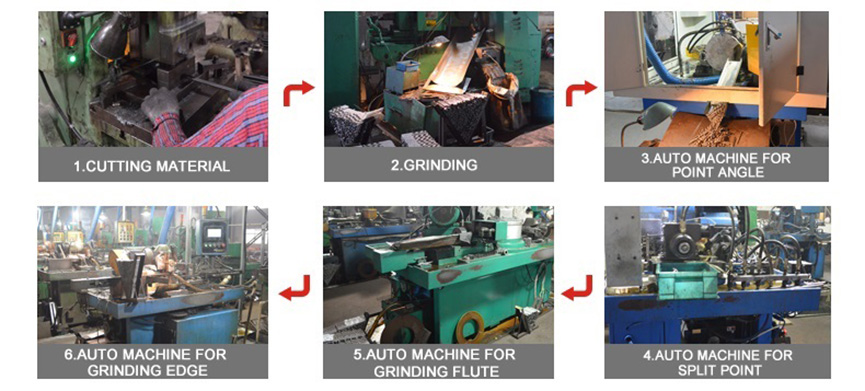

PROCESS FLOW