8PCS Diamond Polishing Pads Set for Masonry

Advantages

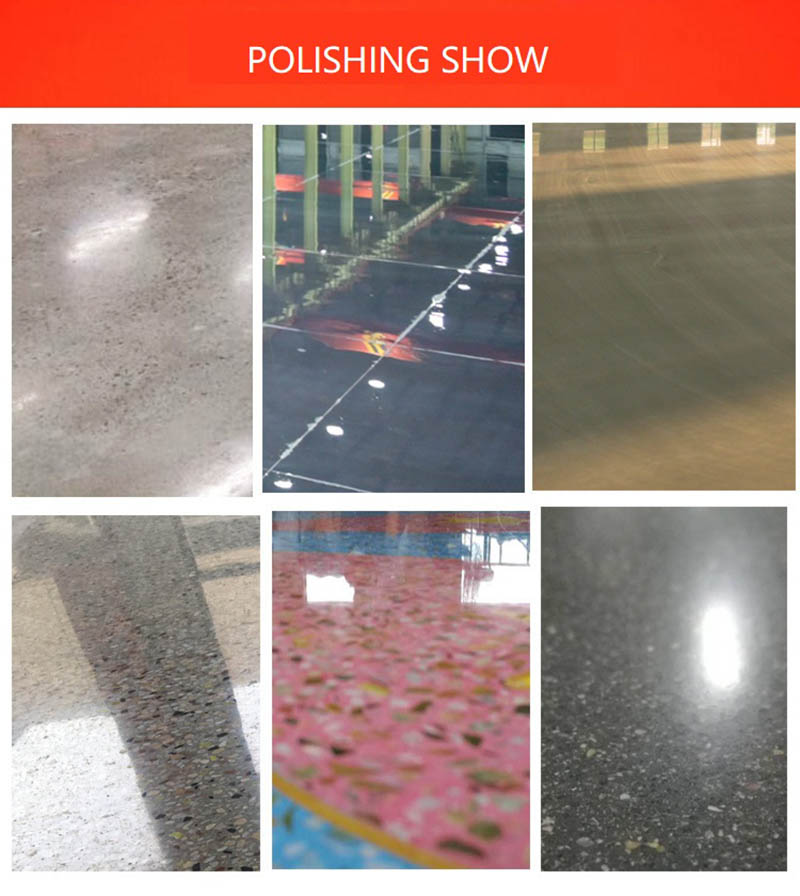

1. Superior polishing performance: Diamond polishing pads are known for their exceptional polishing capabilities. The diamond particles embedded in the pads provide excellent abrasion resistance and allow for precise and efficient polishing of masonry surfaces. This results in a smooth, glossy finish that enhances the appearance of the material.

2. Versatility in applications: These diamond polishing pads are suitable for a variety of masonry materials, including granite, marble, concrete, and other natural stones. This makes them a versatile tool for professionals working in the construction, renovation, and restoration industries. They can be used on different surfaces and shapes, allowing for comprehensive polishing of various masonry projects.

3. Different grit options: The 8PCS set typically includes pads with different grit levels, ranging from coarse to fine. This variety of grit options allows for progressive polishing, starting with more aggressive pads for initial leveling and grinding, and then progressing to finer grits for achieving a higher shine. Having multiple pads at different grit levels in the set provides flexibility and convenience in the polishing process.

4. Long-lasting durability: Diamond polishing pads are designed to withstand the rigors of masonry polishing. The high-quality diamonds and bonding materials used in their construction ensure durability and resistance to wear. This extends the longevity of the pads, reducing the need for frequent replacements and saving costs in the long run.

5. Consistent and even polishing: The diamond particles on the polishing pads are evenly distributed, enabling consistent polishing across the entire surface. This ensures that there are no uneven patches or streaks after polishing, resulting in a professional and uniform finish. Achieving a consistent polish is important for masonry projects that require a seamless and flawless appearance.

6. Easy to use: Diamond polishing pads are typically designed for easy attachment to angle grinders or polishing machines. They can be easily installed and used by professionals or even DIY enthusiasts. The pads' flexibility and adaptability to different machines make them user-friendly and convenient for various polishing applications.

7. Wet or dry polishing options: Diamond polishing pads can be used for both wet and dry polishing methods. When used wet, water acts as a lubricant, cooling the pads and reducing friction. This helps prevent heat damage to the masonry surface during polishing. Dry polishing is suitable for projects where water usage might be challenging or undesirable. Having the flexibility to choose between wet and dry polishing methods provides options to best suit individual project requirements.

8. Cost-effective: Using diamond polishing pads for masonry polishing can be a cost-effective option in the long run. The durability and longevity of these pads minimize the need for frequent replacements. Additionally, the ability to achieve professional results with diamond polishing pads reduces the need for expensive professional polishing services, saving on outsourcing costs.

Product Detail