Ball nose Tungsten Carbide End Mill for aluminium

Features

Features of ball nose carbide end mills designed specifically for aluminum machining include:

1. Made of solid tungsten carbide, with high hardness and wear resistance, very suitable for cutting aluminum and other non-ferrous metal materials.

2.The ball head design allows for smooth contours and contours of aluminum parts, resulting in precisely rounded or sculpted surfaces.

3. Usually coated with a specialized coating, such as TiAlN (Titanium Aluminum Nitride) or AlTiN (Titanium Aluminum Nitride), to enhance heat resistance and reduce friction, improving tool life and performance.

4. The chip removal groove design and chip removal function are optimized for aluminum processing to ensure effective chip removal and prevent chip accumulation during the cutting process.

5. Due to the combination of carbide materials and special coatings, high-speed machining is possible, thereby improving productivity and surface finish.

6. The robust structure and geometry of end mills minimize tool deformation, allowing for stable and precise machining of aluminum parts.

7. Able to produce a high-quality surface finish on aluminum parts, making it suitable for applications where surface aesthetics are important.

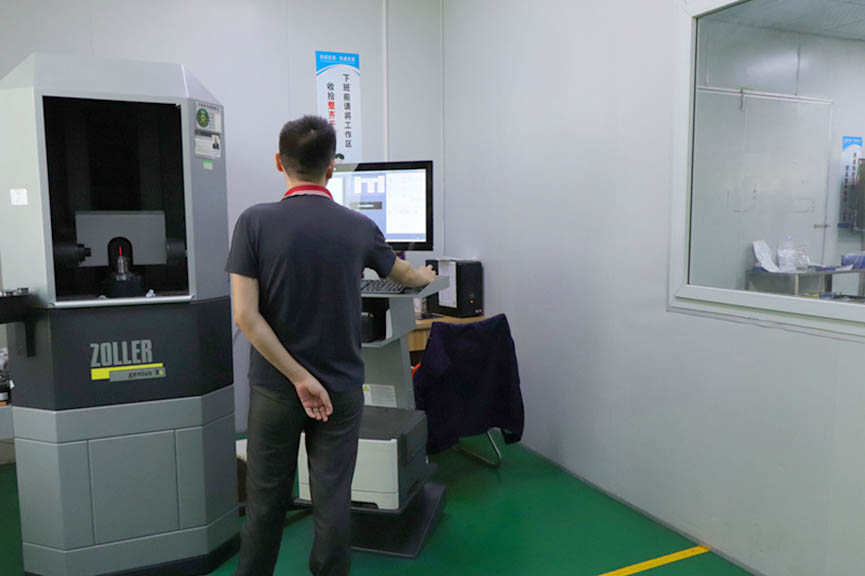

8. Designed to be compatible with CNC machines and milling centers, providing versatility in a variety of aluminum machining applications.

PRODUCT SHOW