Disk type Gear shape HSS Milling Cutter

introduce

Disc gear shaped high speed steel milling cutters are specialized cutting tools designed for specific machining applications. Some of the key features of these knives include:

1. Gear shape design: The cutter has a unique gear shape profile that enables efficient material removal and precise cutting in gear-related applications.

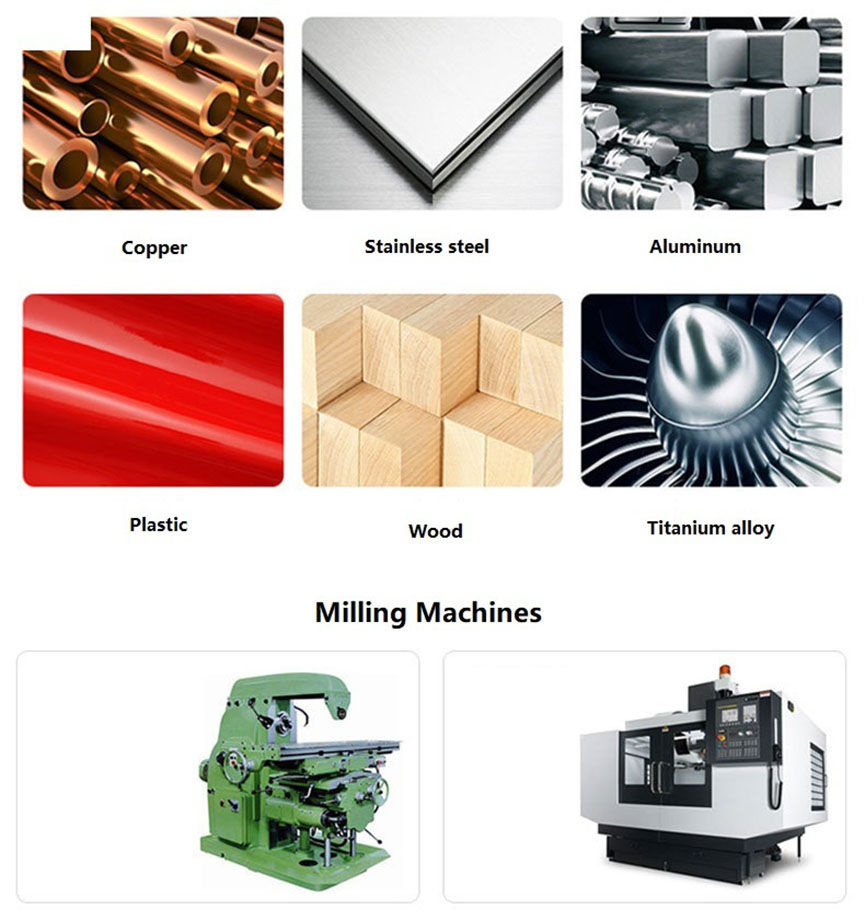

2. High-speed steel structure: These milling cutters are usually made of high-speed steel, which has excellent wear resistance and toughness and is suitable for cutting hard materials such as steel, stainless steel and other alloys.

3. Multiple teeth: The disc gear milling cutter is equipped with multiple cutting teeth, which has a high material removal rate and improves cutting efficiency.

4. Versatility: These tools can be used for a variety of gear-related machining operations, including gear milling, gear hobbing, and gear shaping.

5. Precision machining: Gear shape design can achieve precision machining of gear tooth shapes and ensure the high quality of gear components.

6. Compatibility: These tools are designed to be compatible with a range of milling machines and machining centers, allowing for flexibility in the manufacturing process.

7. Heat resistance: High-speed steel milling cutters are known for their heat resistance, allowing them to withstand higher cutting temperatures without affecting performance.

8. Multiple sizes: Disc gear shape high-speed steel milling cutters are available in a variety of sizes to accommodate different gear diameters and tooth shapes, providing flexibility for different gear manufacturing requirements.

Overall, disc gear shape high-speed steel milling cutters are specialized tools that provide high precision and efficiency in gear-related machining operations, making them an essential tool in gear manufacturing and related industries.

1# 12-13T

2# 14-16T

3# 17-20T

4# 21-25T

5# 26-34T

6# 35-54T

7# 55-134T

8# over 135T