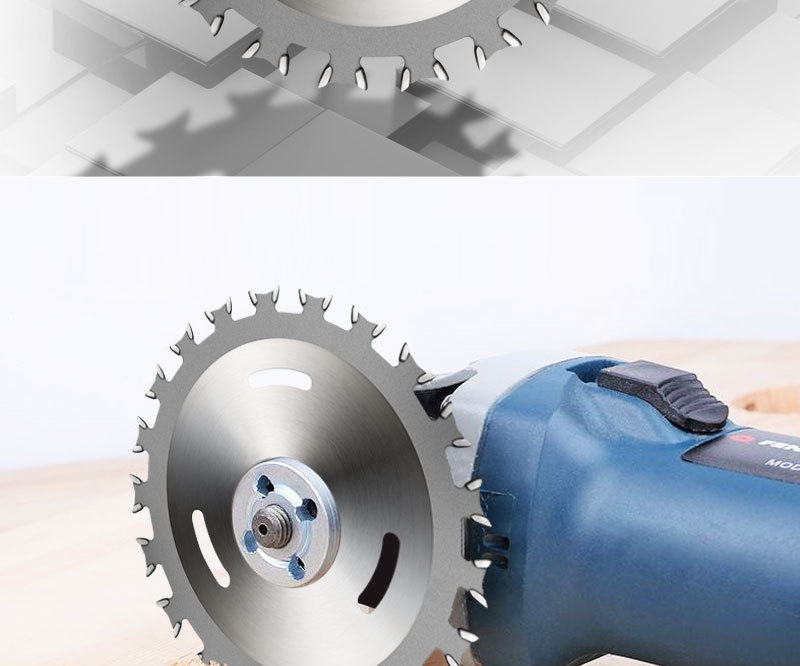

Double direction wood cutting blade for hardworking

Features

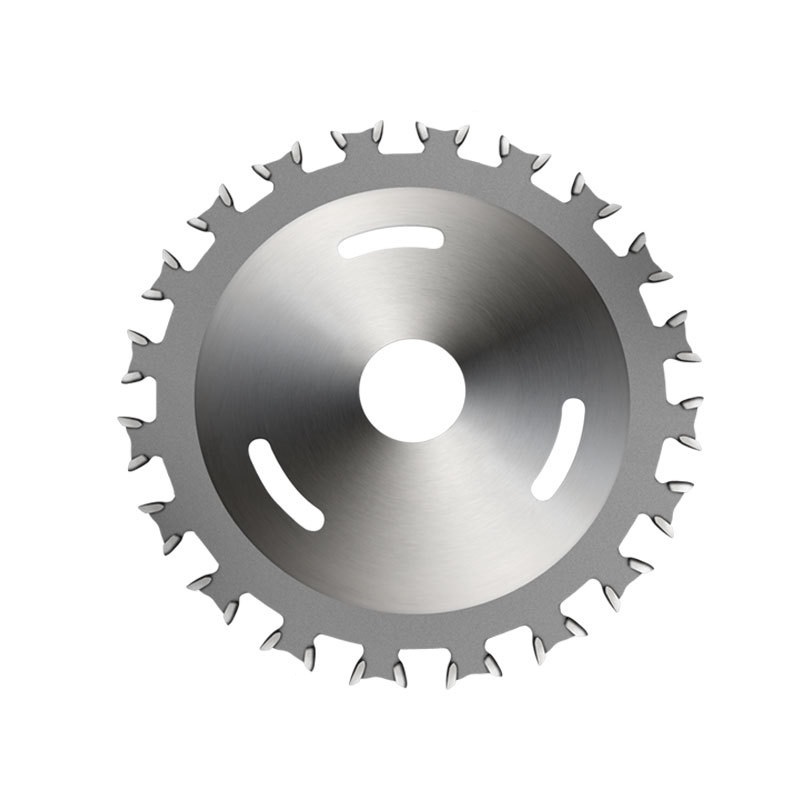

1. Double cutting edges: The blade is designed with cutting edges on both sides to achieve bidirectional cutting. This feature enables the blade to cut efficiently in both forward and reverse directions, increasing productivity and versatility.

2. Tungsten carbide tip: The cutting edge is usually equipped with a tungsten carbide tip, which is extremely hard and durable. This material offers excellent wear resistance and ensures long-lasting cutting performance, especially when working with hard or abrasive wooden materials.

3. Anti-kickback design: The blade can adopt an anti-kickback design to enhance safety during operation. This design helps prevent the blade from catching on the wood and kicking back, reducing the risk of accidents and ensuring a smoother cut.

4. Heat dissipation function: To meet the needs of high-intensity applications, the blade can have a heat dissipation function to help manage the heat generated during the cutting process. This can include specialized slot designs or expanded slots to improve airflow and reduce heat build-up.

5. Precision ground teeth: Cutting teeth are usually precision ground to ensure sharpness and precision, resulting in clean, smooth cuts on hard materials. This feature is essential for obtaining high-quality results in demanding woodworking tasks.

6. Corrosion Resistance: Blades can be coated or treated with materials to provide corrosion resistance, ensuring longevity and performance in challenging work environments.

7. Compatibility: The blade is designed to be compatible with a range of woodworking machinery and can be seamlessly integrated into a variety of cutting applications.

Overall, bi-directional wood cutting blades for tough jobs are designed to deliver superior cutting performance, durability, and safety features to meet the demands of challenging woodworking tasks.

FACTORY

PRODUCT SHOW