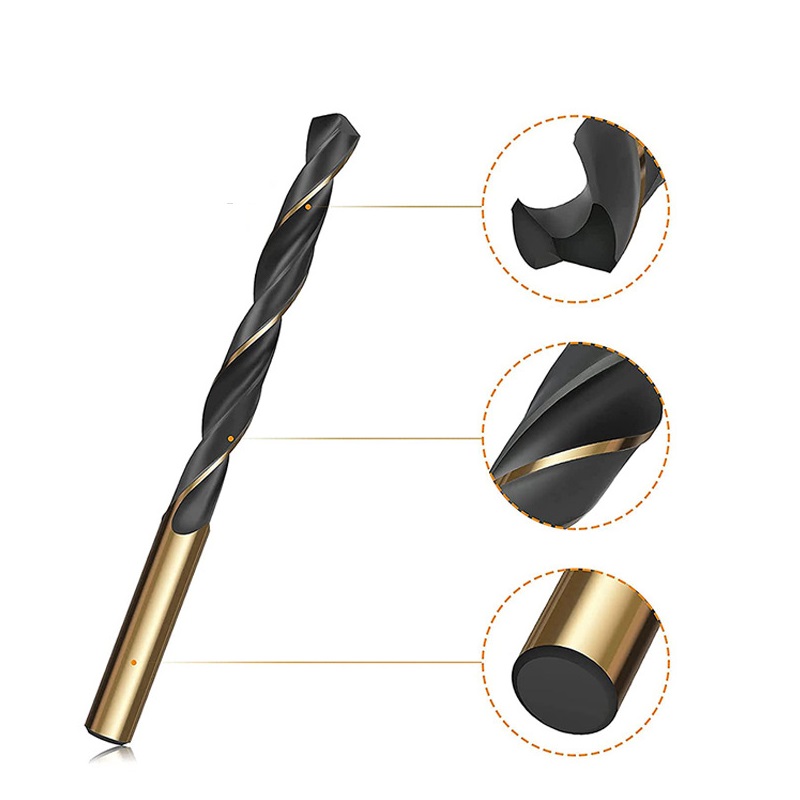

Forged HSS Twist Drill Bits with amber and black coating finish

Features

1.Forged HSS (High Speed Steel) construction provides high hardness and durability, allowing the drill to withstand heavy-duty drilling applications and maintain a sharp cutting edge.

2. Amber and black coatings improve the drill bit’s heat resistance, reducing friction and heat build-up during drilling, helping to extend tool life and maintain drilling efficiency.

3.The coating finish improves wear resistance, reducing the risk of premature dulling and extending the life of the drill bit, especially when drilling through hard materials.

4.Coated surfaces help protect drill bits from corrosion, extending service life and maintaining the integrity of the cutting surface.

5.Coated surface treatment reduces friction during drilling, resulting in smoother operation, less heat generation, and improved chip evacuation.

6.Forged high-speed steel twist drill bits come in amber and black coatings and are suitable for a variety of materials, including metal, wood, plastic and composites, allowing them to be used for different drilling tasks.

7.Designed for precision and accuracy, drill bits produce clean, consistent holes with minimal burrs or distortion.

8.The unique amber and black color combination improves visibility during drilling for better control and accuracy.

Overall, these drill bits combine the strength of forged high-speed steel with the benefits of amber and black coatings to provide durability, heat resistance, wear resistance and versatility for a variety of drilling applications.

PRODUCT show

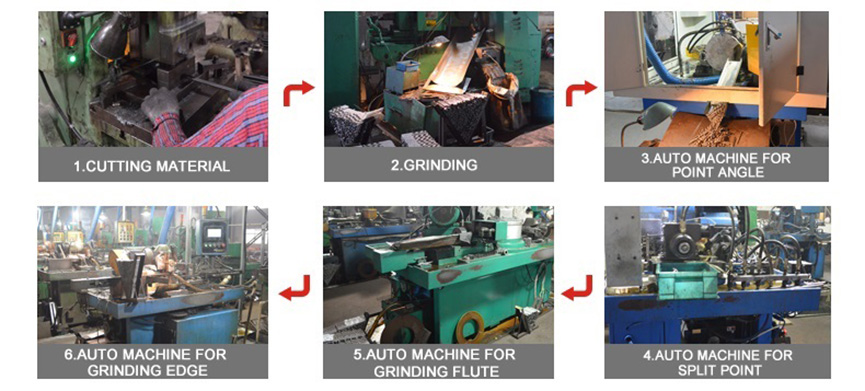

PROCESS FLOW

Advantages

1.Greater Hardness and Durability: Forged high-speed steel construction provides high hardness and durability, making the drill suitable for heavy-duty drilling tasks and allowing it to maintain a sharp cutting edge for a long time.

2.Amber and black coatings increase heat resistance, reducing friction and heat build-up during drilling, helping to extend tool life and continued drilling efficiency.

3.The coated surface treatment improves wear resistance, minimizing premature dulling and extending the overall life of the drill bit, especially when drilling through challenging materials.

4.Coated surfaces help protect drill bits from corrosion, extending service life and maintaining the integrity of the cutting surface.

5.Coated surface treatment reduces friction during drilling, resulting in smoother operation, reduced heat generation and improved chip evacuation, which helps improve drilling performance.

6.Forged high-speed steel twist drill bits are available in amber and black coatings and are suitable for a variety of materials, including metal, wood, plastic and composites, making them suitable for a variety of drilling applications.

7.These drill bits are designed to provide precision and accuracy, resulting in clean, consistent holes with minimal burrs or distortion.

8.The unique amber and black color combination improves visibility during drilling, allowing for better control and accuracy during use.

Overall, these drill bits combine the strength of forged high-speed steel with the benefits of amber and black coatings to provide durability, heat resistance, wear resistance, versatility and enhanced drilling performance for a variety of applications.