Hi Quality Tungsten Carbide Tip Hole cutter for Metal Cutting

Features

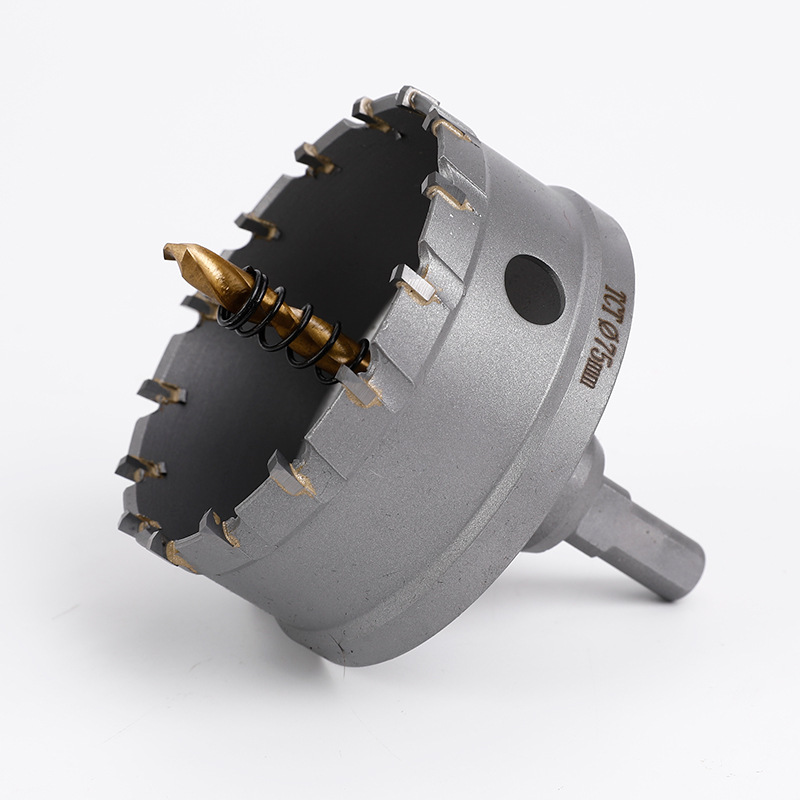

1. A high-quality tungsten carbide tip is used in the construction of the hole cutter. Tungsten carbide is known for its exceptional hardness and strength, making it ideal for cutting through hard metal materials.

2. The hole cutter is designed to provide precise and clean cuts in metal materials. The sharp and durable tungsten carbide tip ensures accurate cutting, minimizing burrs and distortion in the workpiece.

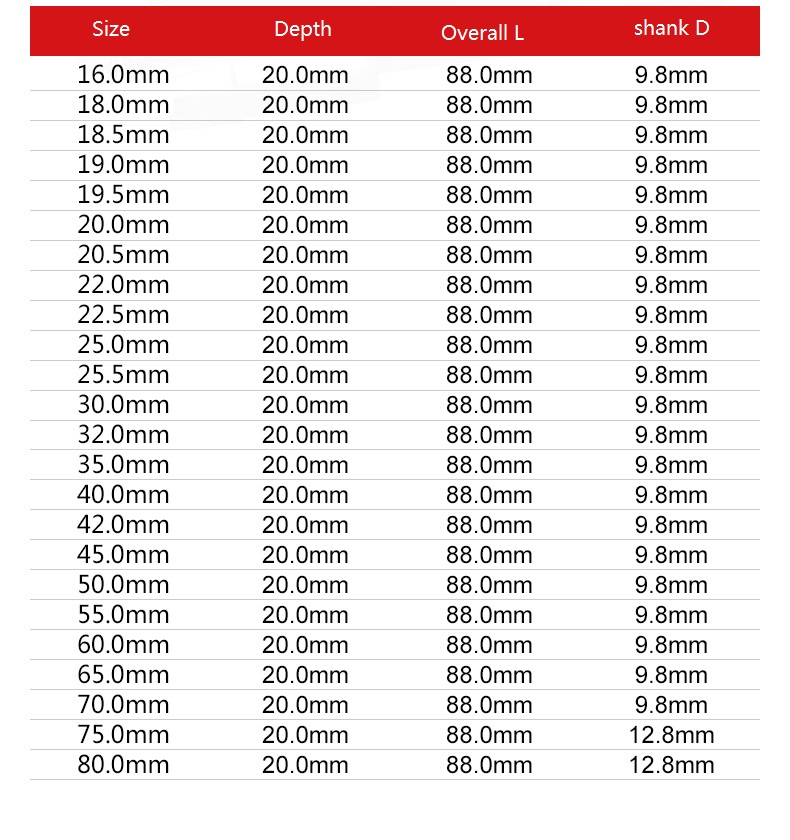

3. Hi-quality tungsten carbide tip hole cutters are available in a range of sizes to accommodate various hole diameters. This allows for versatility and flexibility in metal cutting applications.

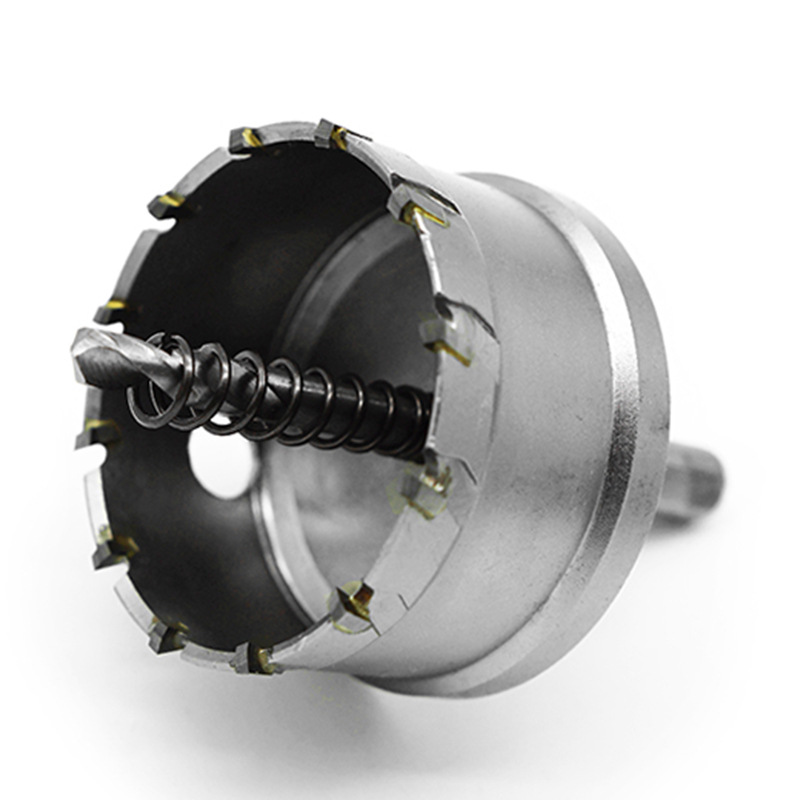

4. The hole cutter is equipped with specially designed flutes or teeth that facilitate efficient chip removal during cutting. This helps prevent clogging and enhances the cutting efficiency and performance of the tool.

5. The high-quality tungsten carbide tip ensures that the hole cutter has a longer lifespan and can withstand tough metal cutting applications. This reduces the need for frequent replacements, saving time and money in the long run.

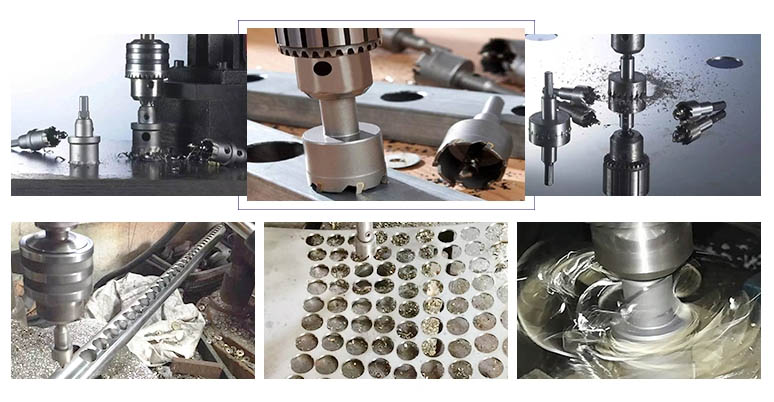

6. The hole cutter is designed for ease of use. It can be easily attached to a drill machine or a compatible arbor, allowing for quick and convenient setup. Additionally, the ergonomic design of the hole cutter ensures comfortable handling during operation.

7. Hi-quality tungsten carbide tip hole cutters can be used for cutting holes in various metal materials, including steel, aluminum, brass, and copper. This makes them suitable for a wide range of applications, such as plumbing, electrical, HVAC, and metal fabrication.

8. The hole cutters are designed to be compatible with standard drill chucks or arbors. This ensures easy installation and secure attachment to the drilling machine.

9. Some hi-quality tungsten carbide tip hole cutters come with safety features, such as a built-in ejector spring or knockout holes, which facilitate easy removal of the cut piece and reduce the risk of injury during operation.

10. Proper maintenance is important for the longevity and optimal performance of the hole cutter. It can be easily cleaned using a brush or compressed air to remove chips and debris, ensuring efficient cutting in subsequent uses.

Product Detail