High Quality DIN353 HSS Machine Tap

Features

1. Material: DIN352 machine taps are made from high-speed steel (HSS), which is known for its excellent hardness and wear resistance properties. This allows for efficient cutting and extended tool life.

2. Thread profiles: DIN352 taps are available in different thread profiles to suit various threading applications. Common thread profiles include metric (M), Whitworth (BSW), Unified (UNC/UNF), and pipe threads (BSP/NPT).

3. Thread sizes and pitch: DIN352 machine taps are available in a wide range of thread sizes and pitches to accommodate different requirements. They can be used for threading a variety of materials and can handle coarse and fine thread pitches.

4. Right-hand and left-hand cuts: DIN352 taps are available in both right-hand and left-hand cutting configurations. Right-hand taps are used for creating right-hand threads, while left-hand taps are used for creating left-hand threads.

5. Taper, intermediate, or bottoming taps: DIN352 taps are available in three different styles - taper, intermediate, and bottoming taps. Taper taps have a more gradual starting taper and are commonly used for starting threads. Intermediate taps have a moderate taper and are used for general threading applications. Bottoming taps have a very small taper or are straight and are used to thread near the bottom of a hole or to cut threads all the way through a blind hole.

6. Chamfer or lead-in design: The taps may have a chamfer or lead-in at the front to ease the starting of the threading process and help guide the tap into the hole smoothly. The chamfered design also helps in chip evacuation during the cutting process.

7. Durability: DIN352 HSS machine taps are designed to withstand the rigors of continuous use. The material and manufacturing process ensure they have good durability, allowing for multiple uses before requiring replacement.

8. Standardized design: The DIN352 standard ensures that the dimensions, tolerances, and geometries of these machine taps are standardized. This enables interchangeability between taps from different manufacturers, providing consistent and reliable threading results.

hand tap detail

factory

specifications

| Items | Specification | Standard |

| TAPS | Straight fluted hand taps | ISO |

| DIN352 | ||

| DIN351 BSW/UNC/UNF | ||

| DIN2181 | ||

| Straight fluted machine taps | DIN371/M | |

| DIN371/W/BSF | ||

| DIN371/UNC/UNF | ||

| DIN374/MF | ||

| DIN374/UNF | ||

| DIN376/M | ||

| DIN376/UNC | ||

| DIN376W/BSF | ||

| DIN2181/UNC/UNF | ||

| DIN2181/BSW | ||

| DIN2183/UNC/UNF | ||

| DIN2183/BSW | ||

| Spiral fluted taps | ISO | |

| DIN371/M | ||

| DIN371/W/BSF | ||

| DIN371/UNC/UNF | ||

| DIN374/MF | ||

| DIN374/UNF | ||

| DIN376/M | ||

| DIN376/UNC | ||

| DIN376W/BSF | ||

| Spiral pointed taps | ISO | |

| DIN371/M | ||

| DIN371/W/BSF | ||

| DIN371/UNC/UNF | ||

| DIN374/MF | ||

| DIN374/UNF | ||

| DIN376/M | ||

| DIN376/UNC | ||

| DIN376W/BSF | ||

| Roll tap/Forming tap | ||

| Pipe thread taps | G/NPT/NPS/PT | |

| DIN5157 | ||

| DIN5156 | ||

| DIN353 | ||

| Nut taps | DIN357 | |

| Combined drill and tap | ||

| Taps and die set |

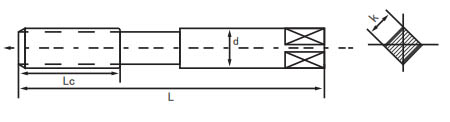

| Size | L | Lc | d | k | bottom hole | |||||

| M2*0.4 | 40.00 | 12.00 | 3.00 | 2.50 | 1.60 | |||||

| M2.5*0.45 | 44.00 | 14.00 | 3.00 | 2.50 | 2.10 | |||||

| M3*0.5 | 46.00 | 11.00 | 4.00 | 3.20 | 2.50 | |||||

| M4*0.7 | 52.00 | 13.00 | 5.00 | 4.00 | 3.30 | |||||

| M5*0.8 | 60.00 | 16.00 | 5.50 | 4.50 | 4.20 | |||||

| M6*1.0 | 62.00 | 19.00 | 6.00 | 4.50 | 5.00 | |||||

| M8*1.25 | 70.00 | 22.00 | 6.20 | 5.00 | 6.80 | |||||

| M10*1.5 | 75.00 | 24.00 | 7.00 | 5.50 | 8.50 | |||||

| M12*1.75 | 82.00 | 29.00 | 8.50 | 6.50 | 10.30 | |||||