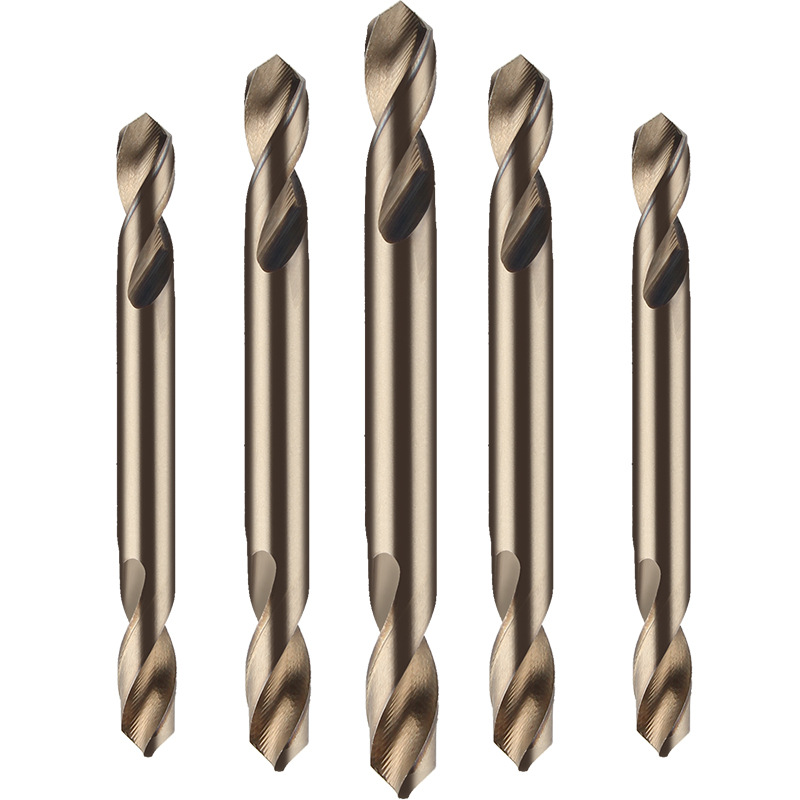

HRC55 ball nose Tungsten Carbide End Mill

Features

The HRC55 ball nose carbide end mill is designed to machine materials up to 55 HRC (Rockwell C) and features a ball nose geometry suitable for contouring and profiling applications. Some key features of the HRC55 ball nose carbide end mill include:

1. Material: Made of solid tungsten carbide, with high hardness and wear resistance, suitable for cutting materials with hardness up to 55 HRC.

2. Ball head geometry enables smooth, precise profiling, contouring and 3D machining, enabling the creation of high-precision rounded or sculpted surfaces.

3. Coating: Often coated with advanced coatings such as TiAlN or AlTiN to enhance heat resistance, reduce friction, and improve wear resistance, thereby extending tool life and improving performance.

4. Chip removal: The chip removal groove design and chip removal function have been optimized to effectively remove chips during the cutting process, prevent chip accumulation, and ensure smooth processing operations.

5. High-speed machining: Due to the combination of carbide materials and special coatings, high-speed machining operations are possible, thereby improving productivity and surface finish.

6. Precision and Surface Finish: Designed to provide high precision and high quality surface finish, making it suitable for applications where precision and surface aesthetics are critical.

7. Versatility: Designed to be compatible with a variety of materials, including hardened steel, stainless steel and other alloys, providing versatility in a variety of machining applications.

PRODUCT SHOW