HSS coarse Milling Cutter

Features

High-speed steel (HSS) roughing cutters offer a variety of advantages for a variety of milling applications. Some of the key advantages of HSS roughing cutters include:

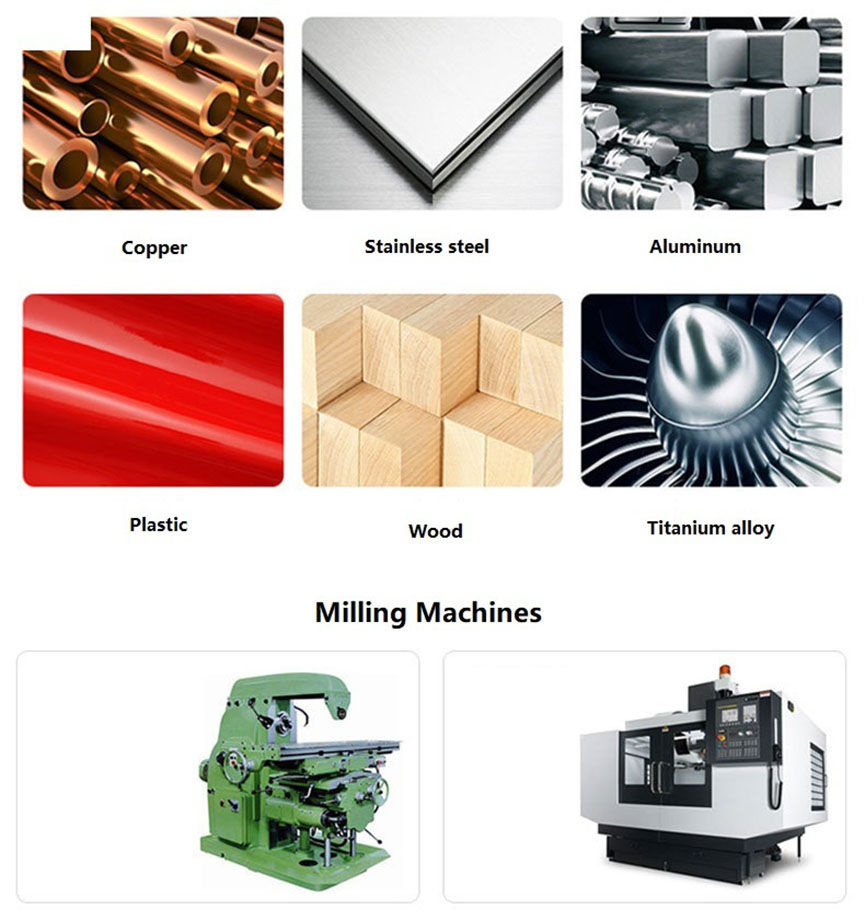

1. High-speed steel roughing milling cutters are suitable for processing a variety of materials, including steel, stainless steel, cast iron and non-ferrous metals, providing versatility in milling operations.

2. High wear resistance: High-speed steel cutting tools are known for their excellent wear resistance, allowing them to maintain cutting performance for a long time, especially when machining tough or abrasive materials.

3. High-speed steel roughing cutters are generally more cost-effective than solid carbide tools, making them the first choice for applications that don’t require high cutting speeds and feeds.

4. Toughness: High-speed steel cutting tools exhibit toughness and durability, allowing them to withstand interrupted cuts, heavy loads, and impact loads without chipping or breaking.

5. Regrinding ability: High-speed steel rough milling cutters can be regrinded multiple times, extending service life and saving costs in the long term.

6. Suitable for low-speed applications: High-speed steel cutting tools are well suited for low-speed milling operations, making them ideal for applications that do not require high cutting speeds.

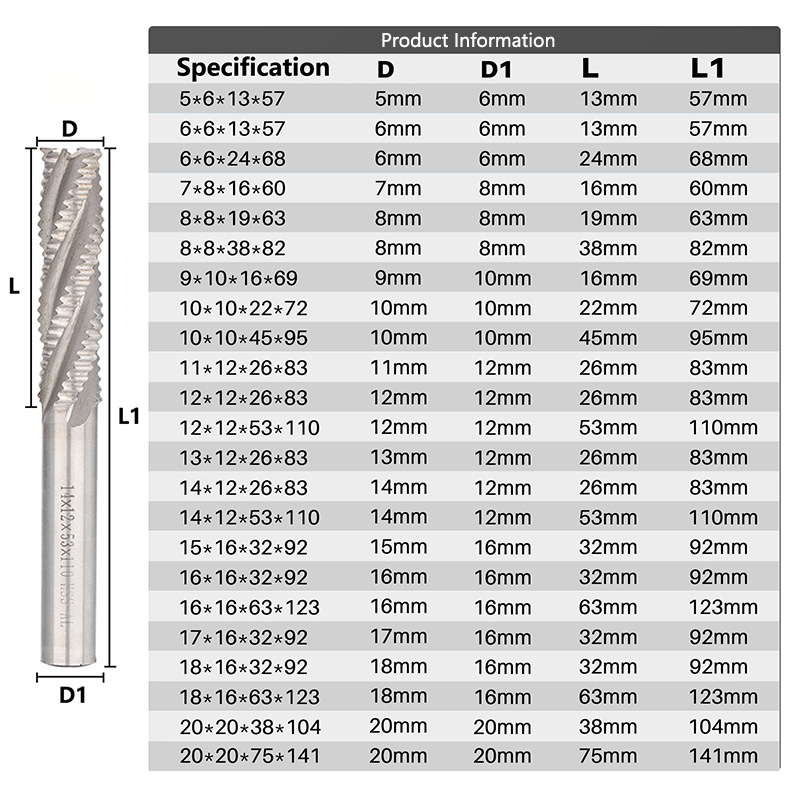

7. Flexibility: High-speed steel roughing milling cutters are available in a variety of sizes and configurations to flexibly adapt to various milling requirements and workpiece geometries.

8. Machining of large workpieces: High-speed steel roughing cutters are suitable for machining large workpieces due to their robustness and ability to handle heavy cutting loads.

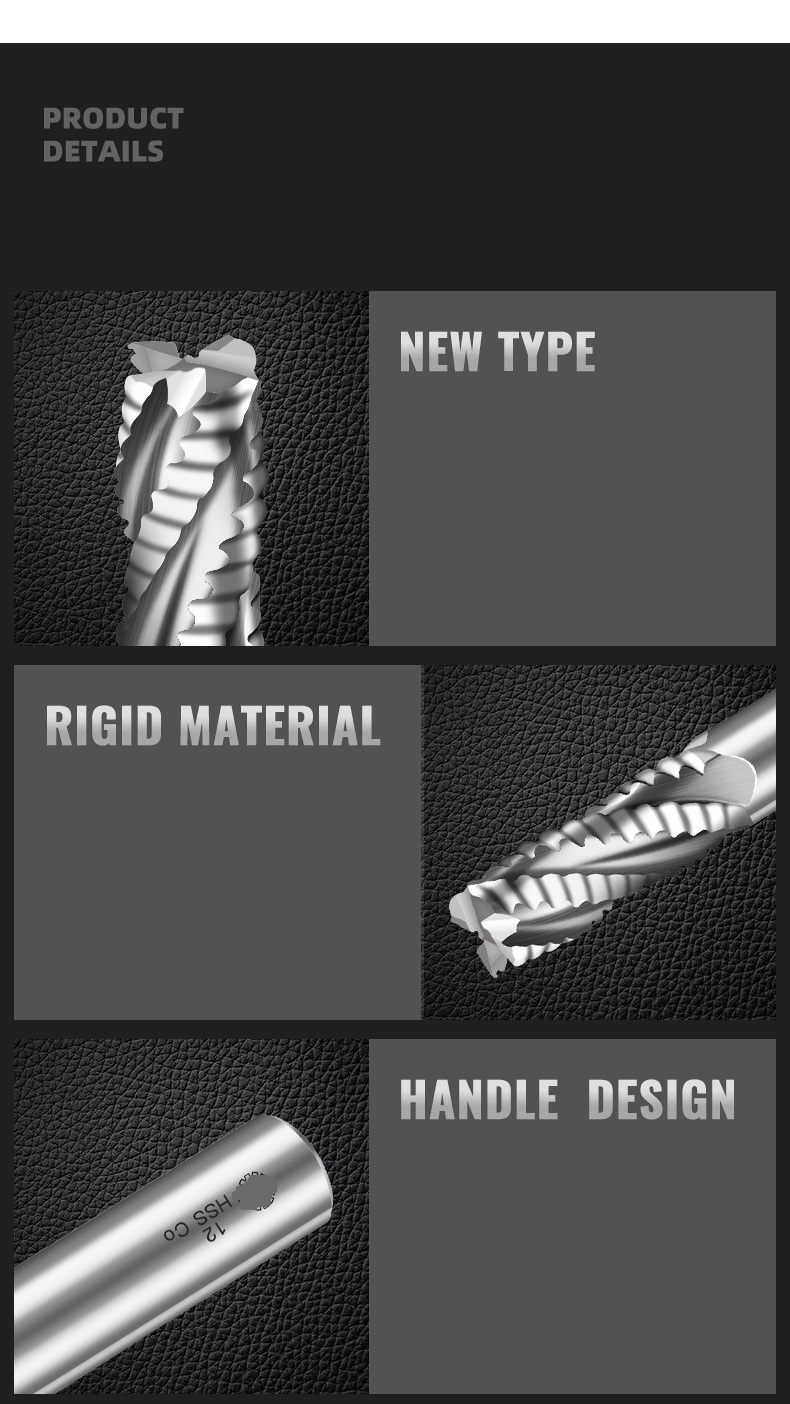

PRODUCT SHOW

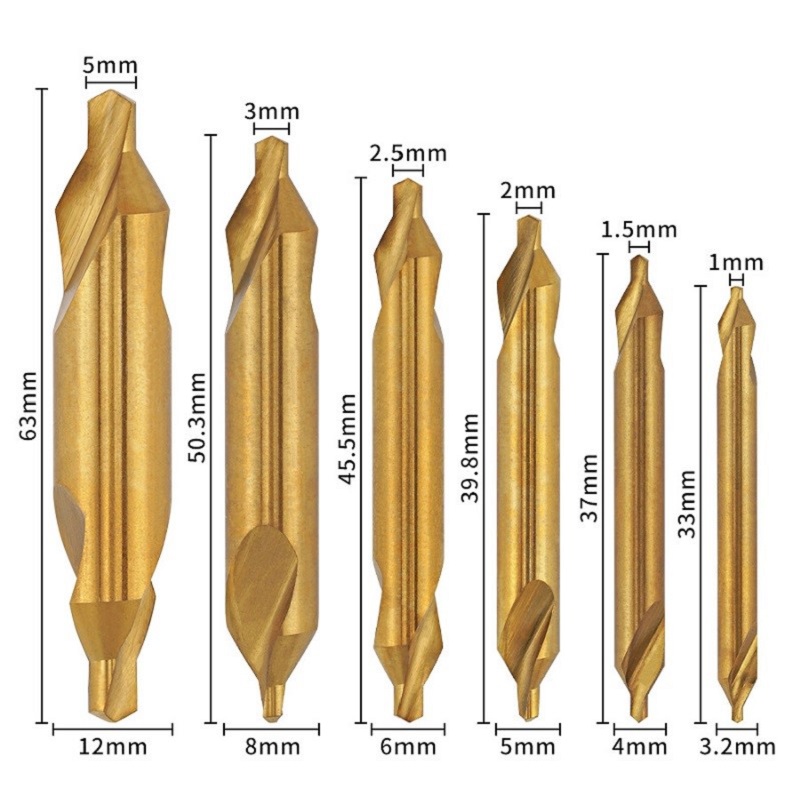

sizes