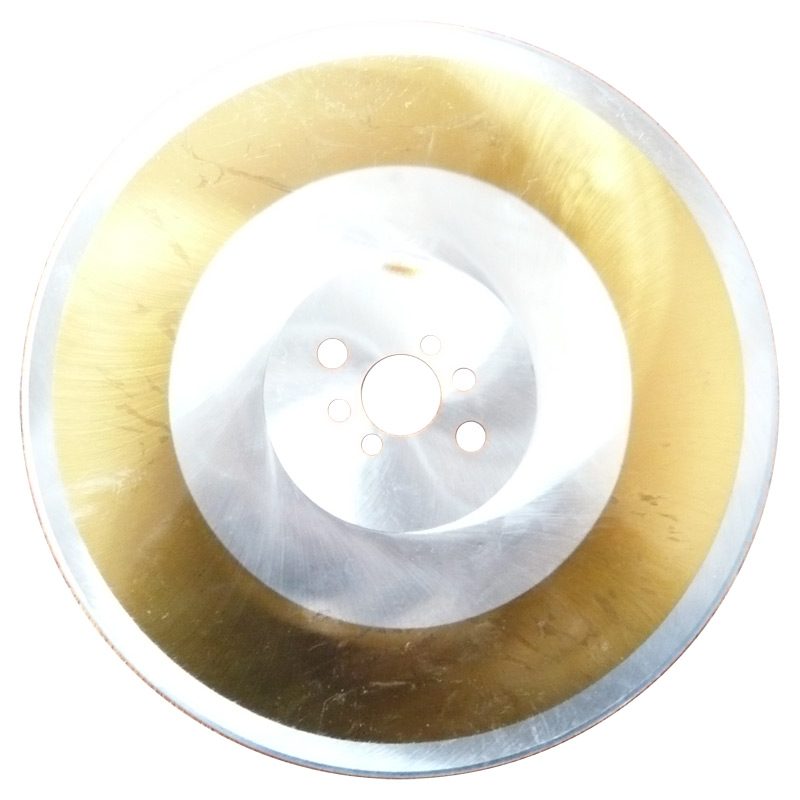

HSS Cobalt M35 Saw Blade for Hard Metal Cutting

Features

1. Hardness and Wear Resistance: HSS cobalt M35 saw blades are made from a high-speed steel alloy that is further enhanced with a 5% cobalt content. This composition gives the blades exceptional hardness, allowing them to maintain their sharp cutting edges for an extended period. This high level of hardness also contributes to their wear resistance, ensuring that they can withstand the abrasive nature of hard metals and maintain their cutting performance.

2. High Heat Resistance: HSS cobalt M35 blades have superior heat resistance thanks to the cobalt content. This feature enables them to handle the elevated temperatures generated during cutting hard metals without compromising their hardness or durability. With increased heat resistance, these blades can effectively dissipate heat, reducing the likelihood of overheating, thermal damage, and premature blade wear.

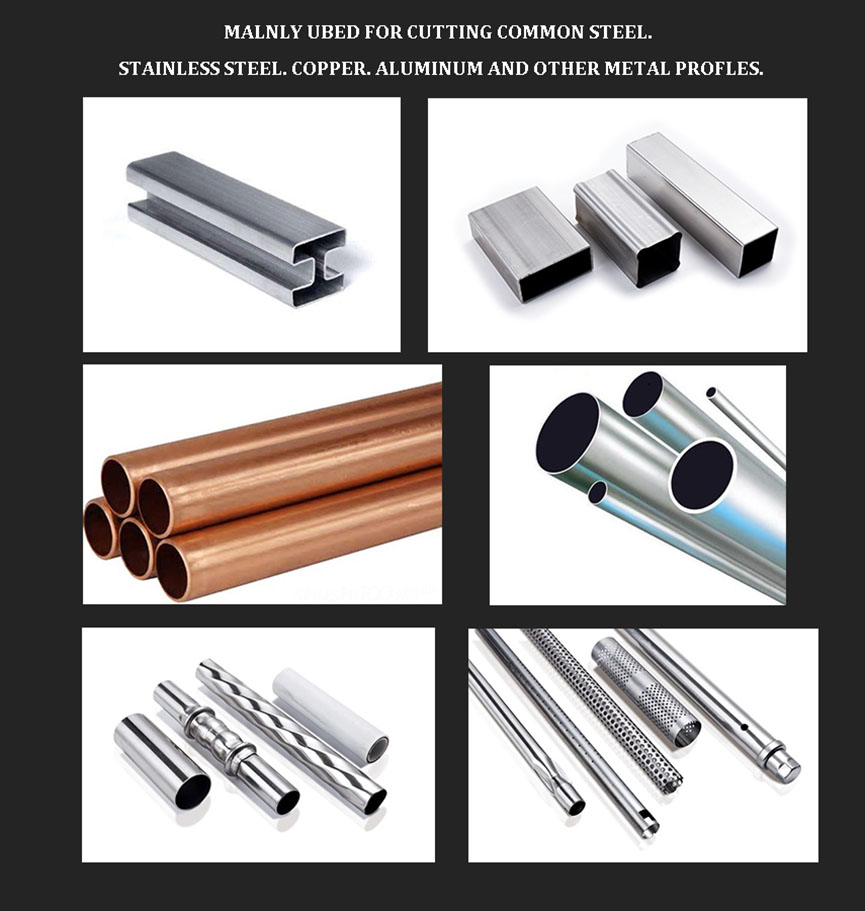

3. Versatility: HSS cobalt M35 blades are versatile and suitable for cutting a wide range of hard metals. These may include stainless steel, alloy steel, tool steel, nickel alloys, and other hardened metals. Their ability to tackle various materials makes them ideal for a variety of applications, such as metal fabrication, machining, and manufacturing.

4. The combination of high hardness, wear resistance, and heat resistance contributes to improved cutting performance. HSS cobalt M35 saw blades provide cleaner, smoother cuts with minimal burrs, reducing the need for secondary finishing operations. They also offer increased cutting speeds and efficiency, ensuring faster and more productive cutting processes.

5. Longer Tool Life: The exceptional hardness and wear resistance of HSS cobalt M35 blades result in a longer tool life compared to standard HSS blades. This extended lifespan helps to reduce downtime, lower tool replacement costs, and increase overall productivity. It also makes these blades a cost-effective choice for cutting hard metals in the long run.

6. Higher Cutting Speeds: HSS cobalt M35 blades allow for higher cutting speeds, thanks to their ability to withstand higher operating temperatures. The enhanced heat resistance and hardness of these blades enable them to maintain their sharpness and cutting performance even at elevated speeds. This increased cutting speed results in more efficient and time-saving cutting operations.

7. Reduced Friction and Cutting Forces: With their unique tooth geometry and enhanced hardness, HSS cobalt M35 blades generate reduced friction and cutting forces during metal cutting. This results in smoother cutting action, less heat generation, and reduced strain on both the blade and cutting machine. It also helps to minimize material distortion or workpiece damage during the cutting process.

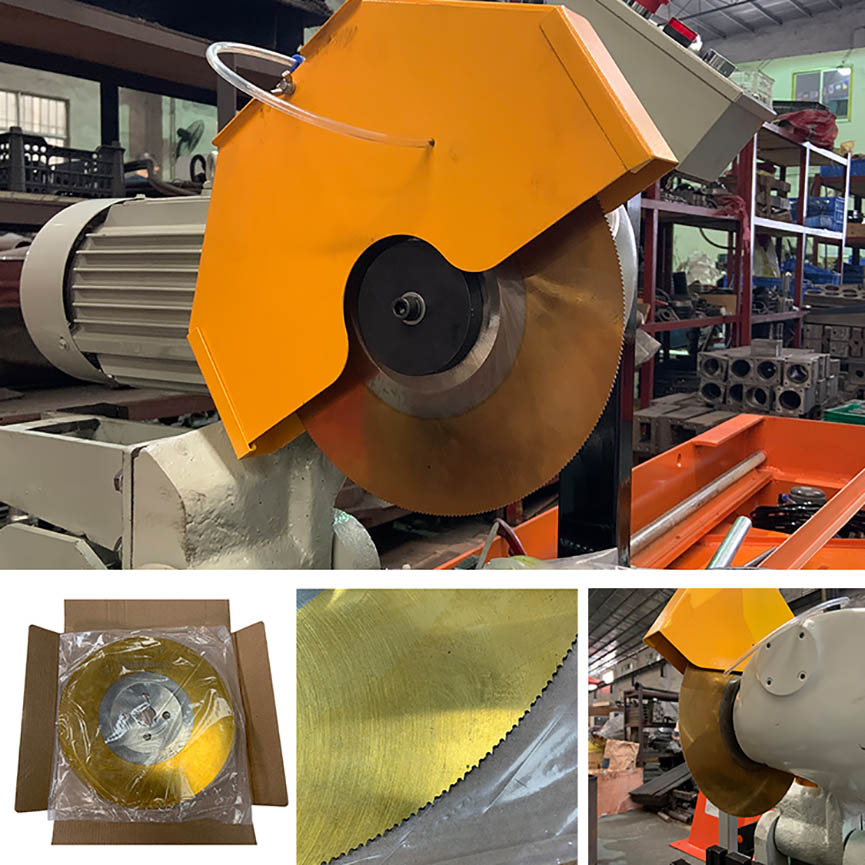

hss cobalt saw blade