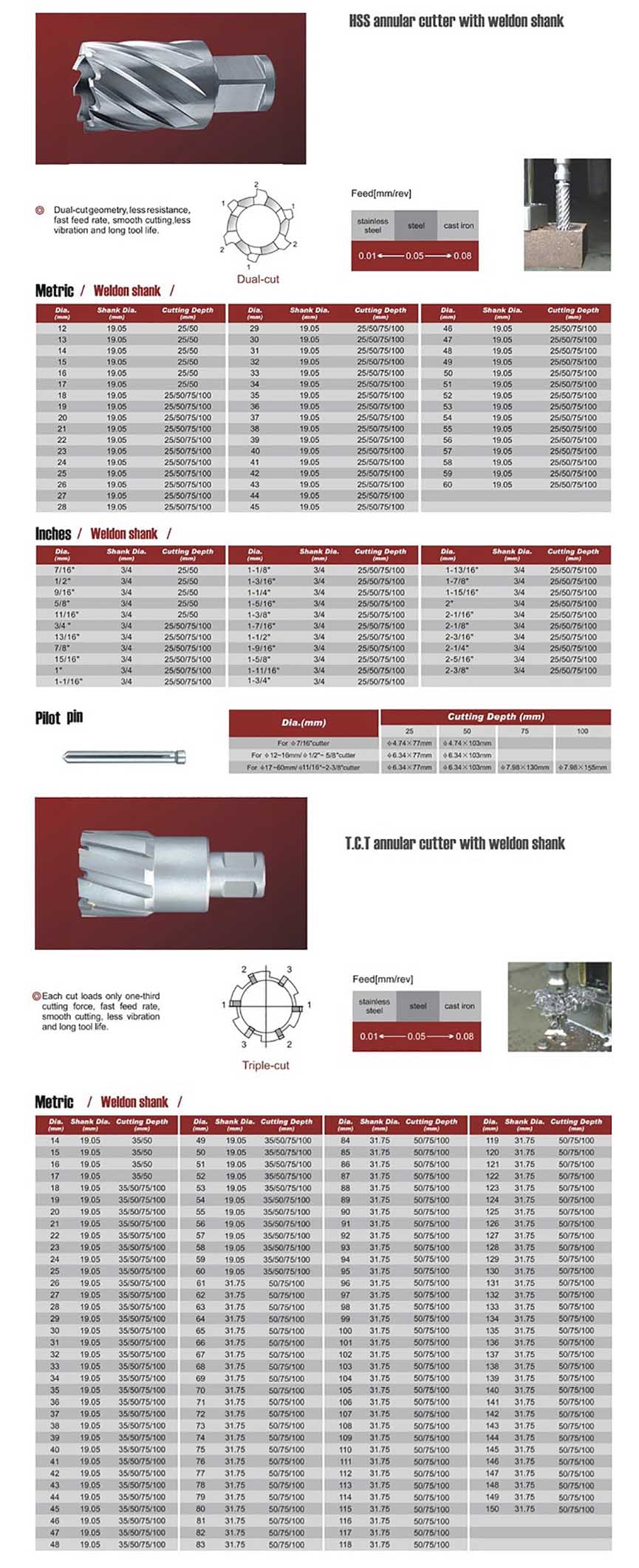

HSS M2 Annular Cutter with Weldon Shank

Features

1. Made of high quality & super tough high speed steel with multi-cut geometry for ply-cutting and lower friction to reach better endurance and less breakage.

2. Suitable for steel (such as T-brackets, large sheets), cast iron, non-ferrous and light metals.

3. Optimised cutting edge geometry for increased cutting performances and reduced cutting forces.

4. The effective cutting angles are designed for universal use in various sorts of steel.

5. Improved removal of chips thanks to U-shaped recesses. The specific geometry of the recess reduces the thermal load on the HSS core drill as the heat created in cutting is removed with the chips to a very great extent.

6. Reduction of the friction between the HSS core drill and the workpiece thanks to optimised spiral-shaped guide chamfers.

7. Weldon shank fit into a majority of magnetic drills.

FIELD OPERATION DIAGRAM

Advantages

1. High-Speed Steel Construction: HSS annular cutters are made from high-speed steel, a type of tool steel that is known for its hardness, durability, and resistance to wear and heat. This construction ensures that the annular cutter can withstand high-speed drilling and maintain its performance even in demanding conditions.

2. Faster and Efficient Cutting: Compared to traditional twist drill bits, annular cutters are specifically designed for hole cutting applications. Their unique geometry, along with the teeth or flutes on the cutting edge, allows for faster and more efficient material removal. This speed and efficiency reduce the overall drilling time, increasing productivity.

3. Precise and Accurate Cuts: HSS annular cutters produce clean, burr-free, and accurately sized holes. The pilot pin or centering pin, along with the well-designed cutting edges, enable precise positioning and drilling, resulting in high-quality and professional-looking finished holes.

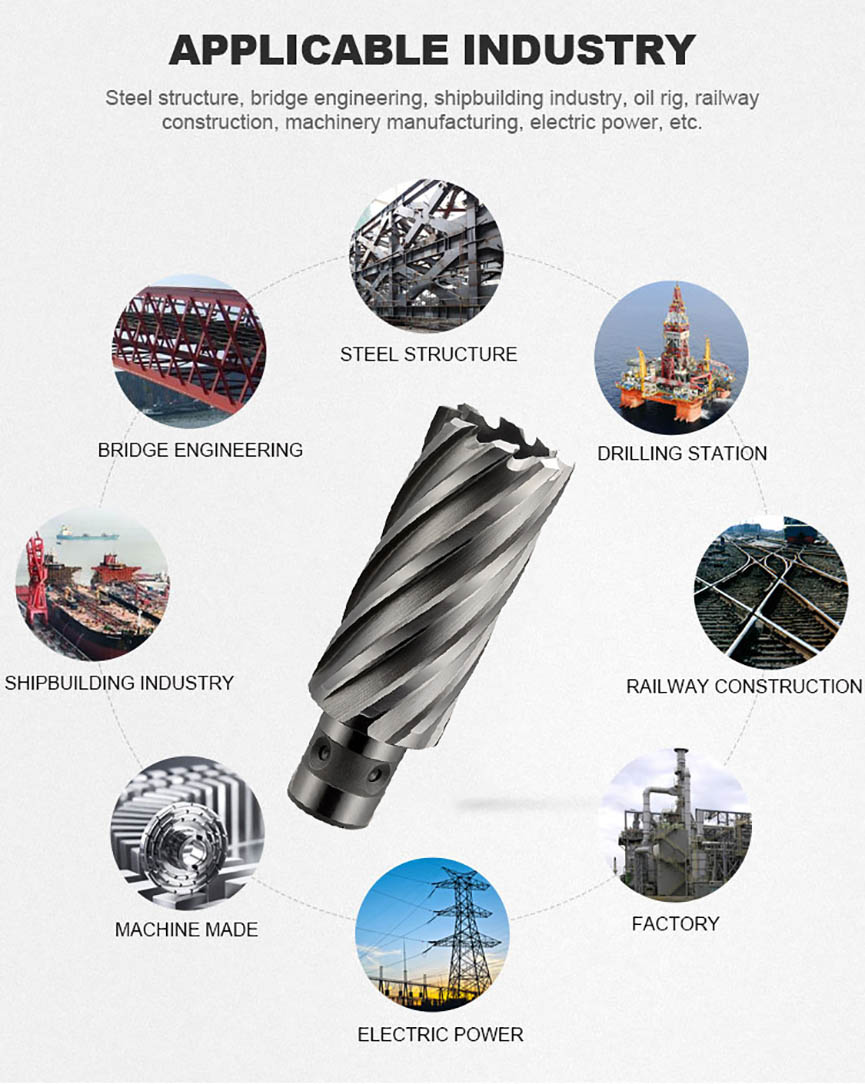

4. Versatility: HSS annular cutters can be used on various ferrous and non-ferrous materials, including steel, stainless steel, aluminum, copper, brass, and more. This versatility makes them suitable for a wide range of applications in industries such as construction, manufacturing, metalworking, and fabrication.

5. Improved Chip Evacuation: Annular cutters have hollow centers, allowing for efficient chip evacuation during drilling. This feature prevents chip clogging and ensures better heat dissipation, prolonging the tool life and maintaining consistent cutting performance.

6. Compatibility with Magnetic Drilling Machines: HSS annular cutters are designed for use with magnetic drilling machines. The cutters can be securely attached to the machine's magnetic base, providing stability, accuracy, and ease of use during drilling operations.