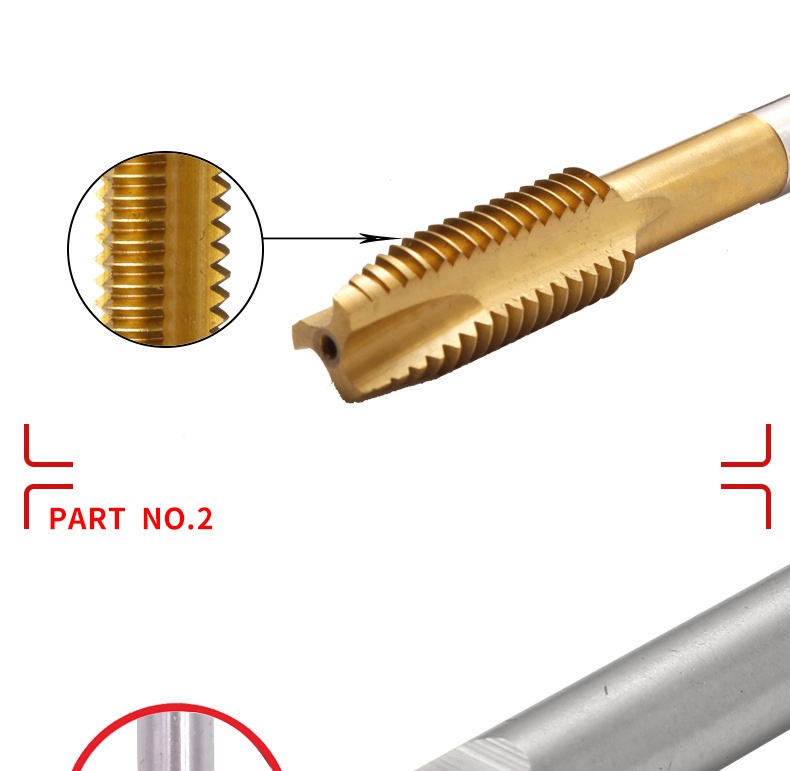

HSS Machine Tap with titanium coating

Advantages

HSS (High Speed Steel) machine taps with titanium coating have a variety of properties that make them suitable for a variety of threading applications. Some key features include:

1. Titanium coating provides enhanced hardness and heat resistance, thereby extending tool life and improving performance in high-temperature applications.

2. The use of high-speed steel as the base material ensures durability and toughness, allowing the tap to withstand the rigors of metal cutting and threading.

3. Titanium coating enhances the lubricity of the tap, reduces friction and heat generation during the cutting process, and contributes to smoother and more efficient tapping.

4. The titanium coating provides a protective layer that enhances the wear resistance of the tap, making it suitable for demanding machining tasks and extending its service life.

5. High-speed steel machine taps with titanium coating are suitable for a variety of materials, including steel, stainless steel, aluminum and other alloys, making them suitable for a variety of industrial and manufacturing applications.

6. These taps are designed to produce precise and clean threads, ensuring a proper fit and secure connection between fasteners.

7. Titanium-coated high-speed steel machine taps are generally compatible with a variety of tapping machines and hand tools, allowing for flexible use in different machining setups.

Detailed diagram