HSS morse Taper machine Reamers

Features

High Speed Steel (HSS) Morse Taper Machine Reamers are precision tools designed for enlarging and finishing existing holes in machine parts. Some of the key features of high-speed steel Morse taper machine reamers include:

1. Morse Taper Shank: These reamers are designed with Morse taper shank for safe and accurate installation in the spindle or sleeve of the machine.

2. High-speed steel structure: High-speed steel Morse taper machine reamers are usually made of high-speed steel, which has excellent hardness, wear resistance and heat resistance, and is suitable for a variety of materials, including steel, stainless steel, and non-ferrous metals.

3. Precision cutting edges: These reamers are designed with precision ground cutting edges that ensure accurate and smooth hole expansion, resulting in a high-quality surface finish.

4. Straight grooves: High-speed steel Morse taper machine reamers usually have straight grooves, which help to effectively remove chips and debris during the reaming process, helping to improve cutting performance.

5. Tapered Design: The tapered design of these reamers allows for easy insertion into pre-drilled holes and ensures proper alignment for precise reaming.

6. Versatility: High-speed steel Morse taper machine reamers are suitable for a variety of applications, including machine shops, metalworking and general engineering tasks.

7. Meet standards: Many high-speed steel Morse taper machine reamers are manufactured to industry standards such as DIN, ISO or ANSI, ensuring consistent quality and performance.

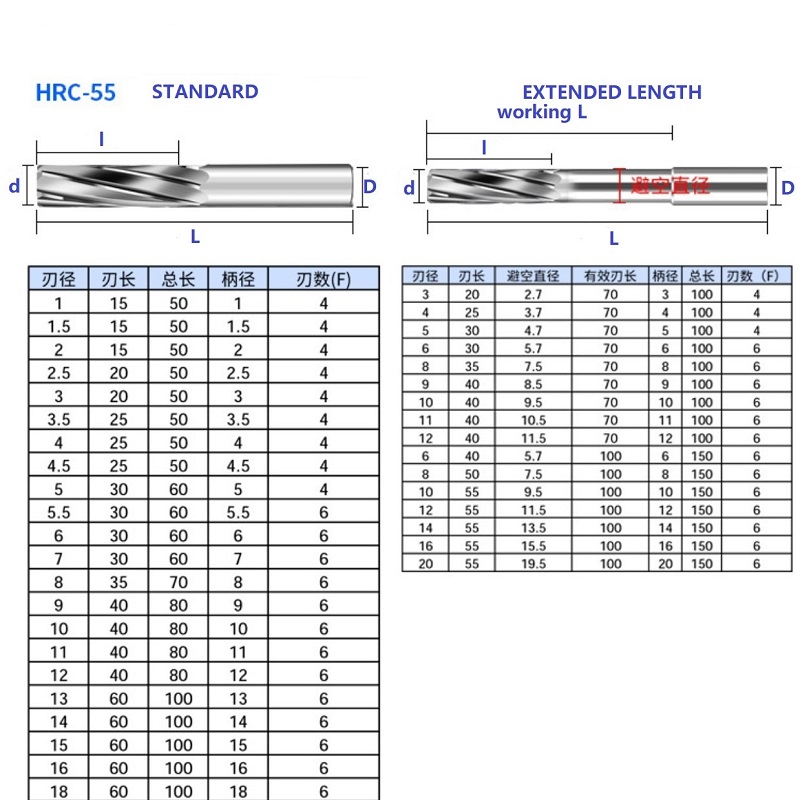

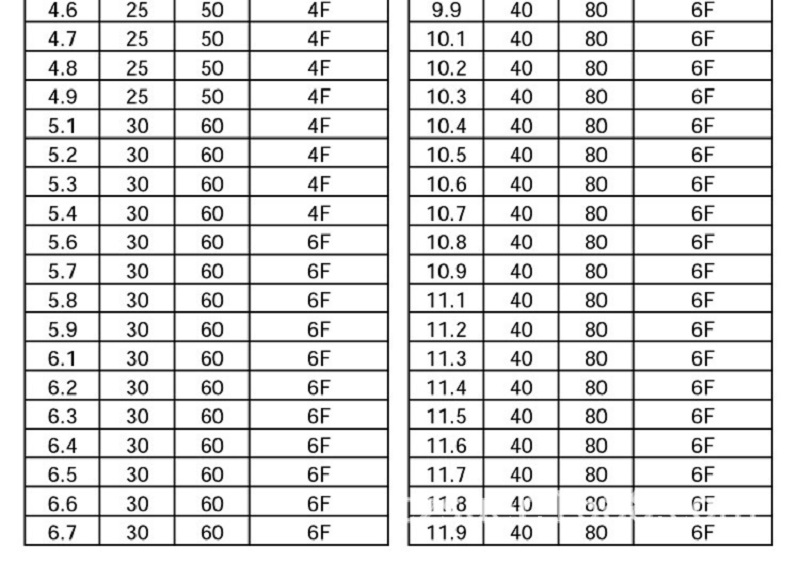

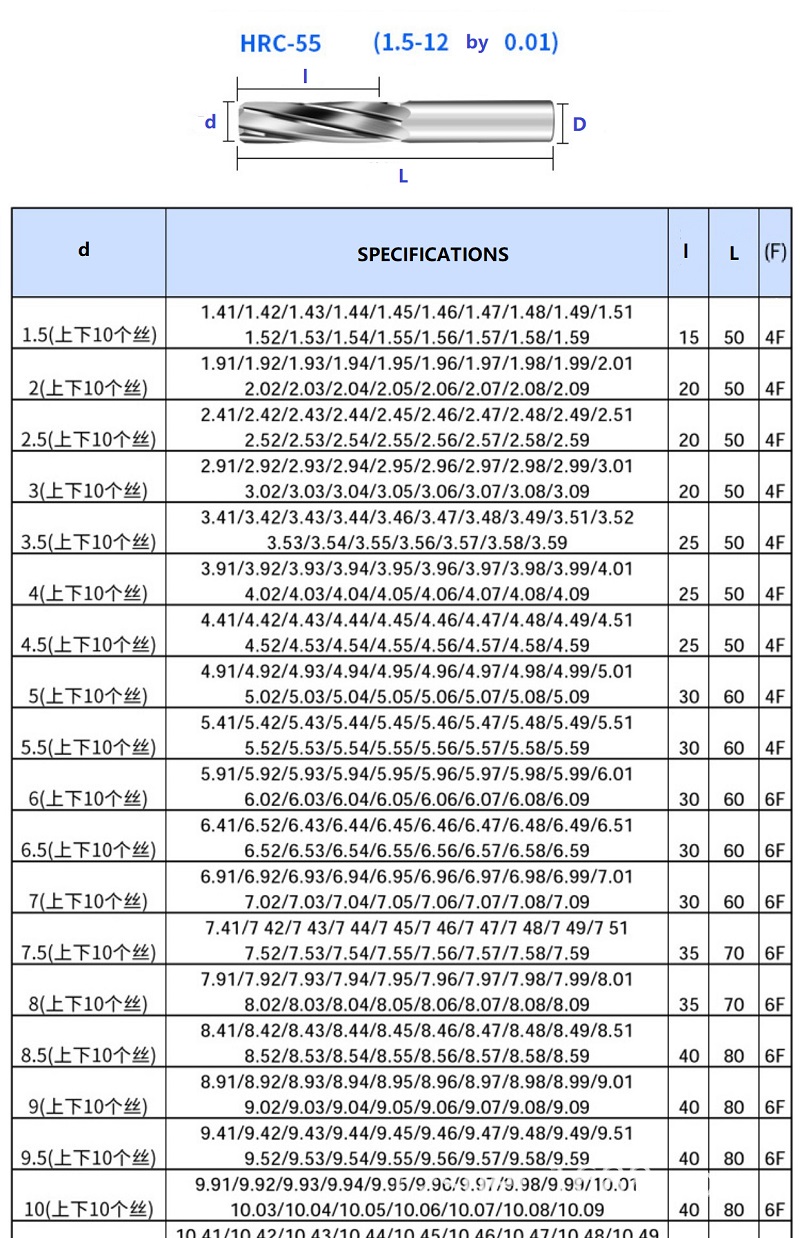

8. Available in various sizes: These reamers are available in various sizes to suit different hole diameters and processing requirements.

PRODUCT SHOW