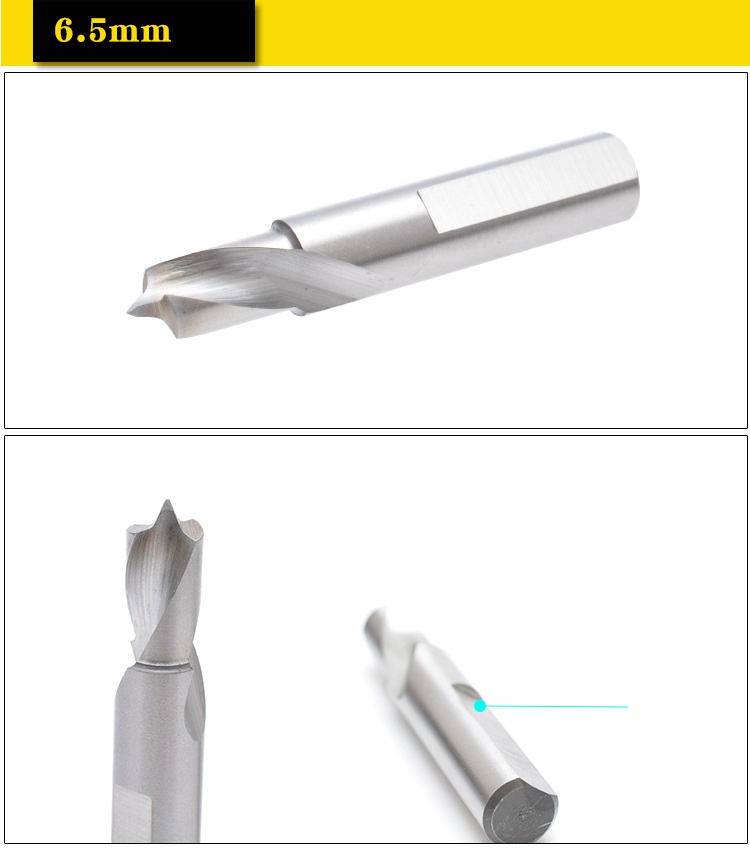

HSS Spotweld remover twist Drill Bit

Features

1.Cobalt Structure: High-speed steel (HSS) containing cobalt alloys is often used to increase hardness, heat resistance and durability.

2.Groove Geometry

3.Many spot weld remover drill bits are equipped with a pilot point or centering tip to provide precise and controlled drilling, minimizing the risk of slippage and damage to surrounding material.

4.High Heat Resistance:

PRODUCT SHOW

INSTALLATION

Advantages

1. Precision: It is designed to precisely locate and drill out solder joints without damaging the surrounding metal, ensuring precise, clean removal.

2.DURABILITY: High-speed steel construction provides excellent durability and wear resistance, allowing the drill to withstand the demands of spot weld removal without dulling quickly.

3.Efficient Chip Evacuation: The twisted design and groove geometry are optimized for efficient chip evacuation, preventing clogging and maintaining cutting performance during spot weld removal.

4.Compatibility: Drill bits are typically designed to be compatible with a variety of drilling machines, making them versatile and suitable for different spot welding applications.

5.Versatility: It can be used to remove spot welds from a variety of materials, including automotive body panels, sheet metal and other metal fabrication projects.

6.Reduces heat build-up: The design of the drill helps minimize heat build-up during drilling, extending tool life and reducing the risk of damaging surrounding materials.

These advantages make the HSS Spot Weld Remover Twist Drill a valuable tool for efficient spot weld removal in automotive repair, metal fabrication, and other industrial applications.

| Dia | Shank size | O.Length |

| 6.5 | 8 | 41 |

| 8 | 8 | 41 |