Industrial Grade Tungsten Carbide Saw Blade for Hard Metal Cutting

Advantages

1. Exceptional Durability: Industrial-grade tungsten carbide saw blades are specifically designed to withstand the high temperatures and extreme pressures encountered when cutting hard metals. They have a higher resistance to wear and can maintain their cutting performance even in challenging conditions.

2. High Precision Cutting: These saw blades are engineered to deliver accurate and precise cuts on hard metals. The carbide tips are designed to stay sharp, ensuring clean and smooth cuts, reducing the need for additional finishing work.

3. Extended Lifespan: Industrial-grade tungsten carbide saw blades have a longer lifespan compared to other saw blades. The exceptional hardness of tungsten carbide combined with its resistance to abrasion and wear allows these saw blades to withstand repetitive cutting tasks on hard metals, resulting in less frequent blade replacements.

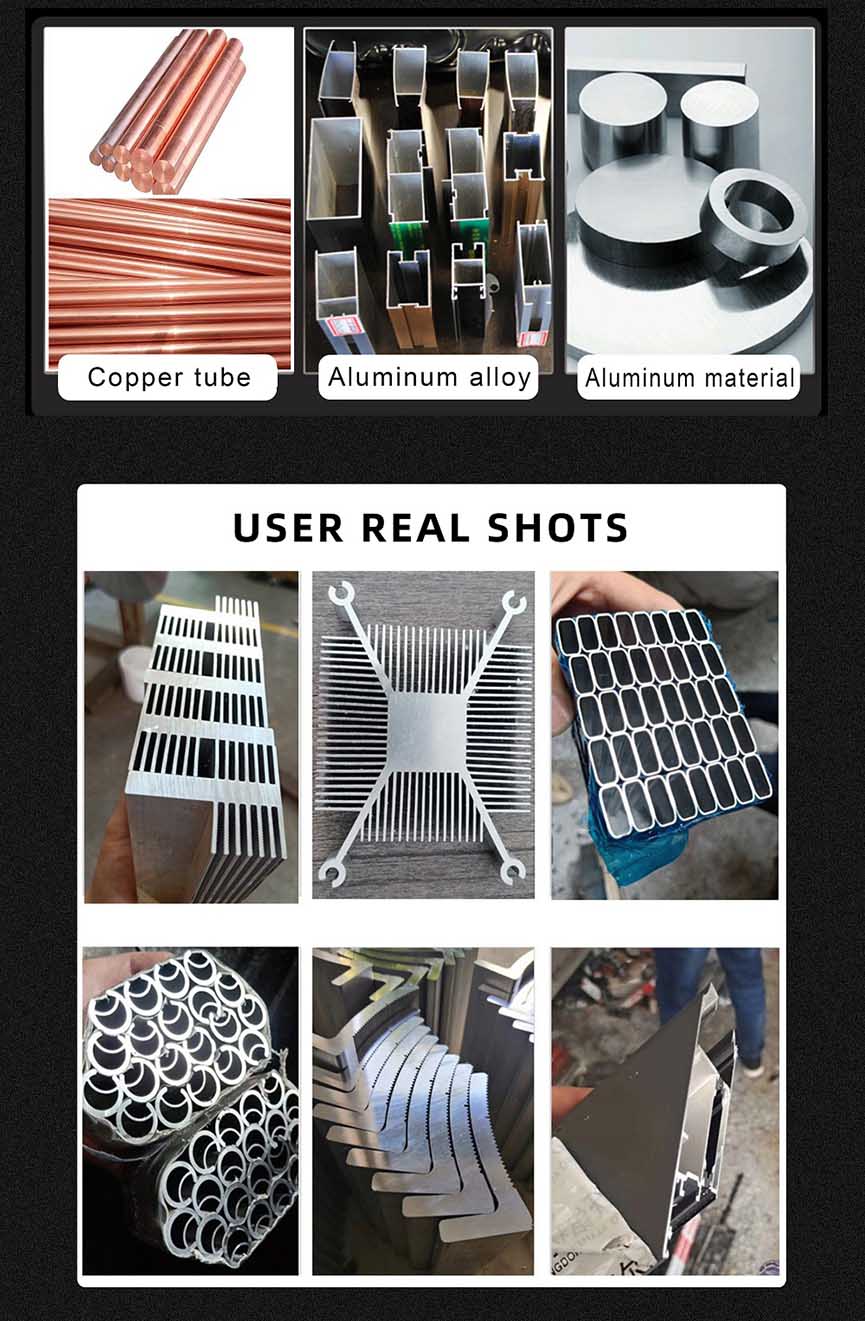

4. Versatility: Tungsten carbide saw blades can be used on a wide range of hard metals such as stainless steel, cast iron, and various alloys. This versatility makes them an ideal choice for industrial applications where different types of hard metals need to be cut.

5. Reduced Heat and Friction: These saw blades are designed to minimize the heat generated during cutting. The carbide tips have a low coefficient of friction, reducing frictional heat buildup, which can cause premature blade wear. This feature also helps to prevent the workpiece from warping or overheating during the cutting process.

6. Improved Productivity: Industrial-grade tungsten carbide saw blades enable faster cutting speeds and improved cutting efficiency on hard metals. The combination of durability, precision, and extended lifespan reduces downtime and increases productivity in industrial operations.

FACTORY

TCT saw blade packaging

| Diameter(mm) | Kerf(mm) | Body(mm) | Bore(mm) | Teeth type | Number of teeth |

| 255 | 2.8 | 2.2 | 25.4/30 | BT | 100/120 |

| 305 | 3.0 | 2.4 | 25.4/30 | BT | 100/120 |

| 355 | 3.2 | 2.6 | 25.4/30 | BT | 100/120 |

| 405 | 3.2 | 2.6 | 25.4/30 | BT | 100/120 |

| 450 | 4.0 | 3.2 | 25.4/30 | BT | 100/120 |

| 500 | 4.4 | 3.6 | 25.4/30 | BT | 100/120 |

| Remarks: Can be customized according to drawings | |||||