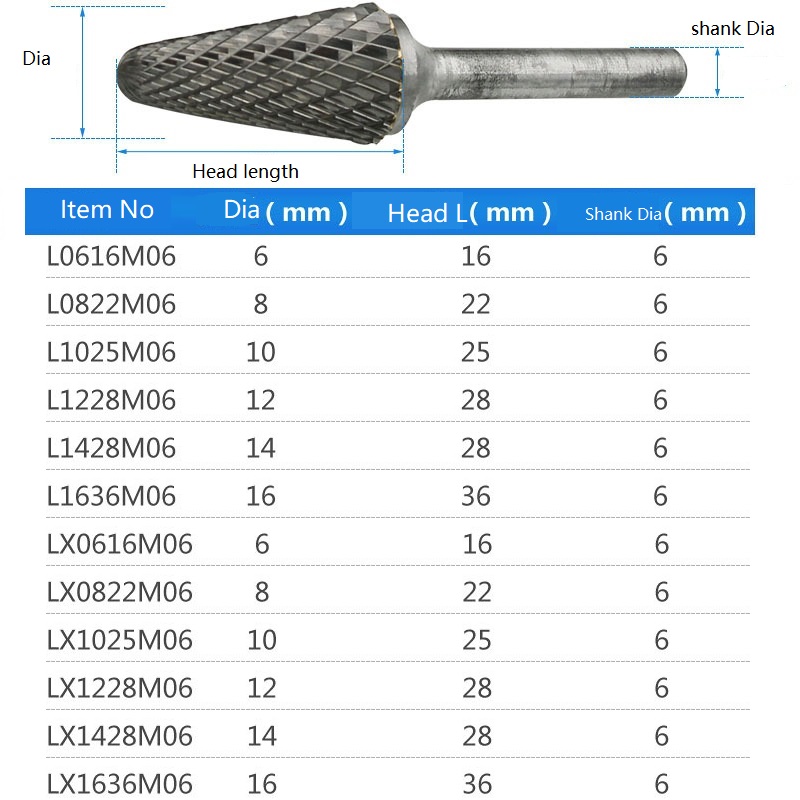

L type Tungsten carbide Burr with taper shape and radius end

Advantages

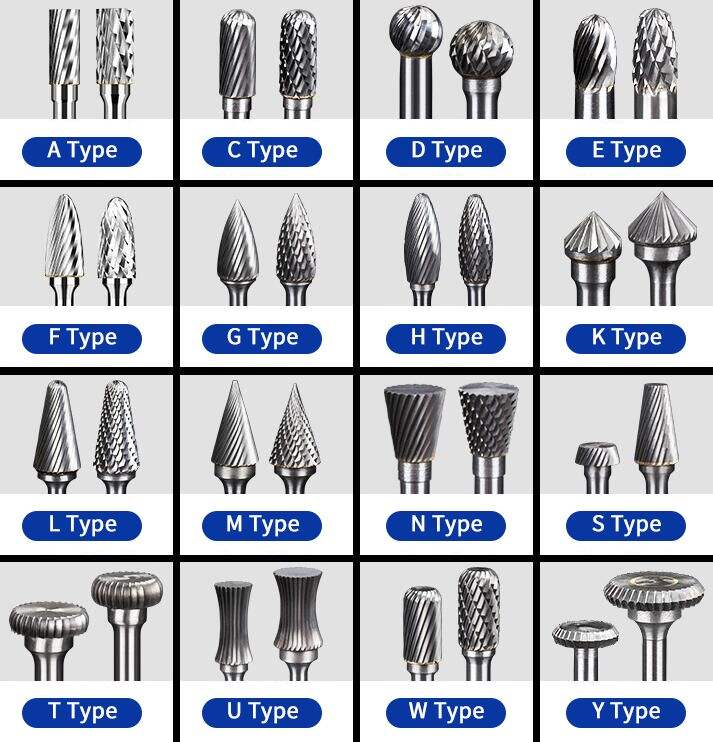

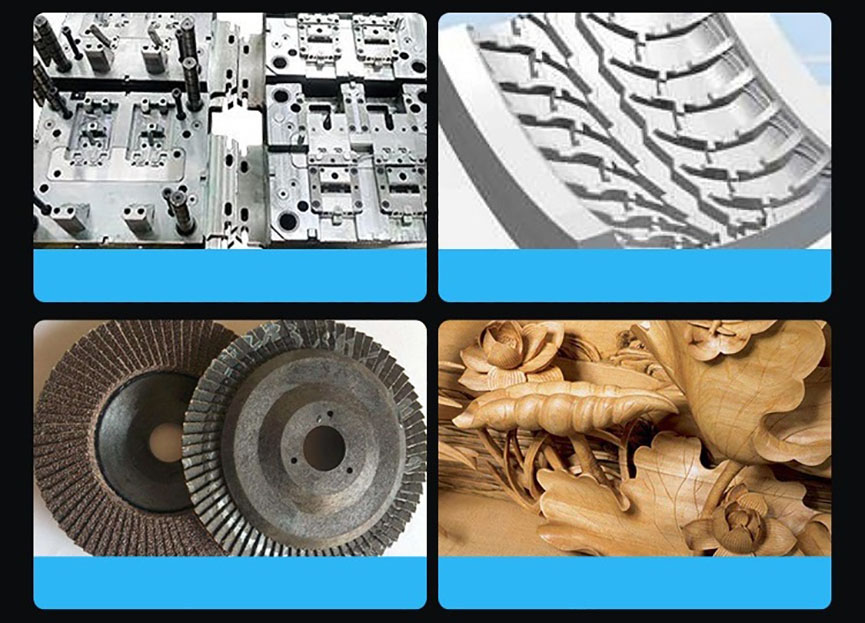

L-shaped tungsten carbide burrs with tapered and radiused ends are versatile, making them suitable for a variety of cutting and shaping applications:

1. Contouring and shaping: The tapered shape with rounded ends can effectively contour and shape materials, making them suitable for tasks such as deburring, chamfering and engraving.

2. Smooth finish: The radial end of the burr helps achieve a smooth finish on the workpiece, reducing the need for additional finishing operations.

3. Access small spaces: The tapered shape of the burr allows access to small or hard-to-reach areas, making it suitable for complex and detailed work.

4. Reduce chatter: The design of the burrs helps minimize chatter and vibration during operation, thereby improving surface finish and reducing tool wear.

5. Efficient Material Removal: The tapered shape with rounded ends enables efficient material removal, making it suitable for tasks that require fast cutting or forming.

6. Long service life: Tungsten carbide is a durable and long-lasting material that extends tool life and reduces tool replacement frequency.

7. Heat resistance: Tungsten carbide has high heat resistance, allowing the milling cutter to maintain its cutting edge even at high speeds and high temperatures.

8. Compatibility: The L-shaped tool holder design ensures compatibility with a variety of rotary tools, making it easy to integrate into existing tool setups.

Overall, the L-shaped tungsten carbide burr with tapered and radiused ends offers precision, versatility, and durability, making it a valuable tool for a variety of cutting and shaping applications, especially those requiring detailed and intricate work. application.

PRODUCT SHOW