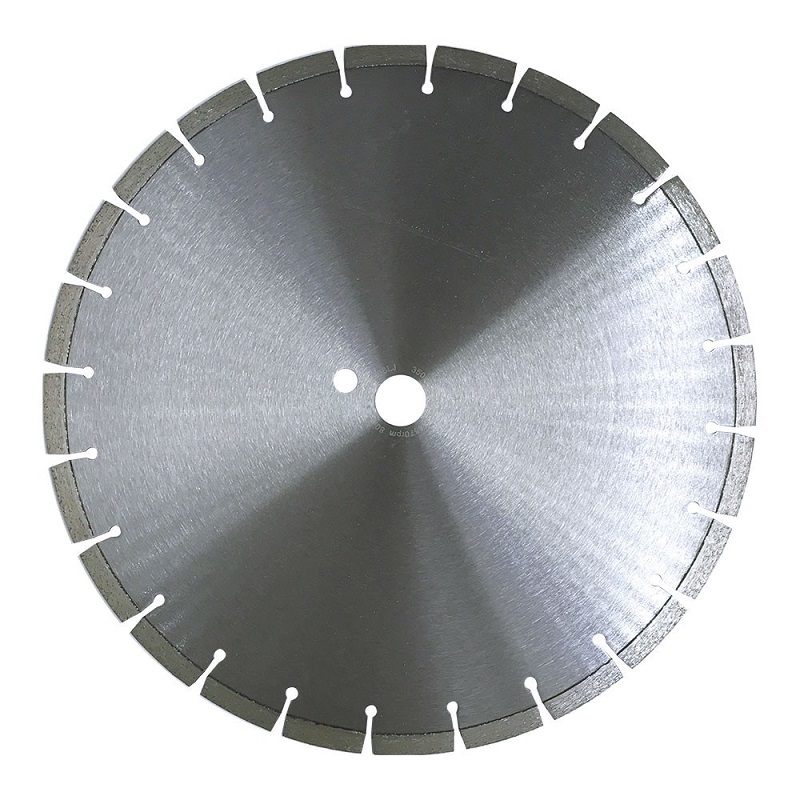

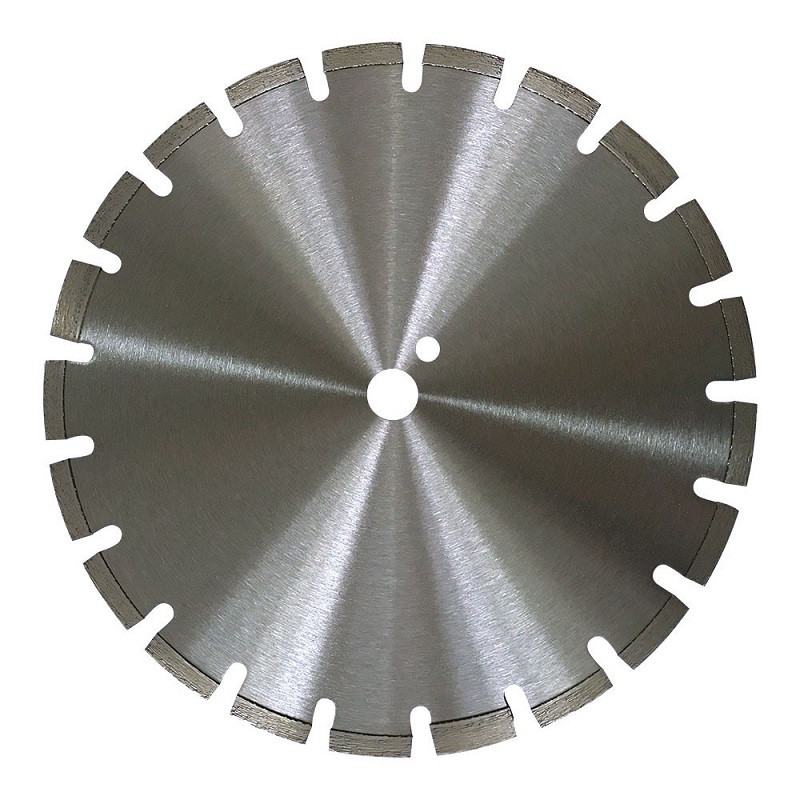

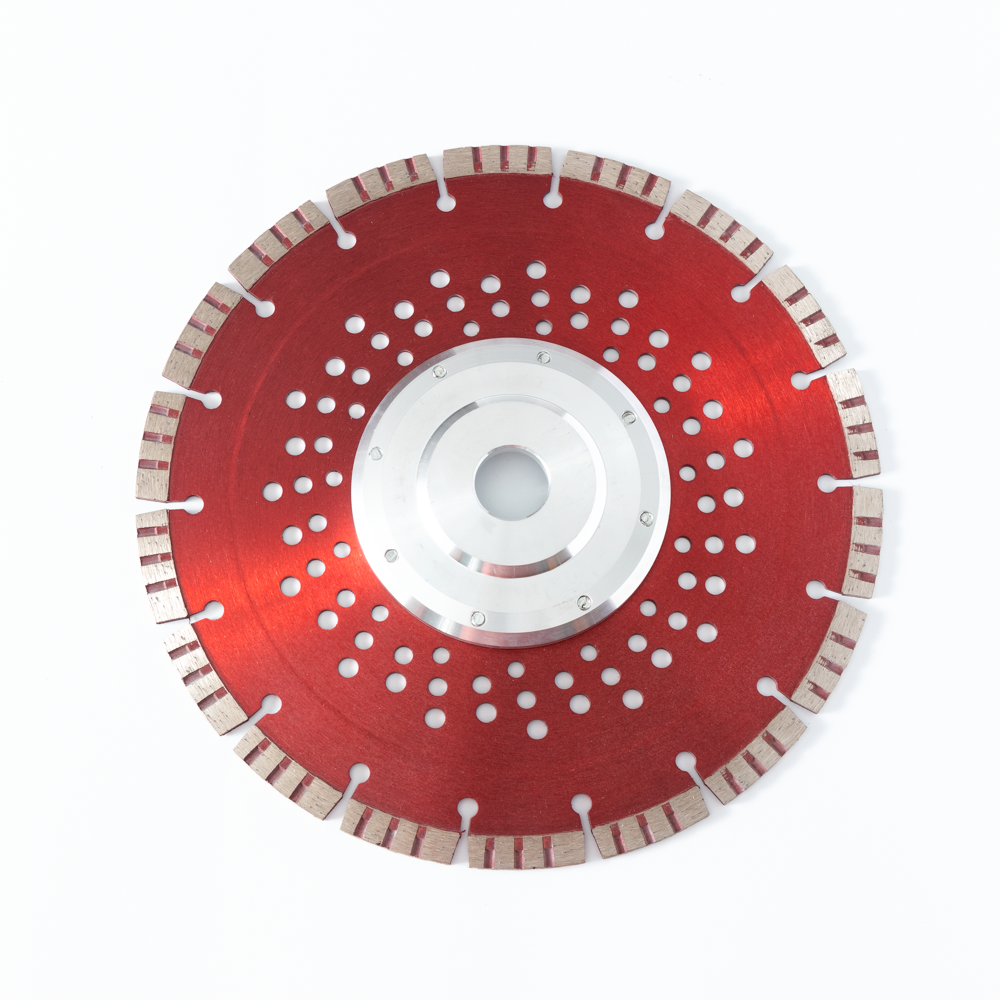

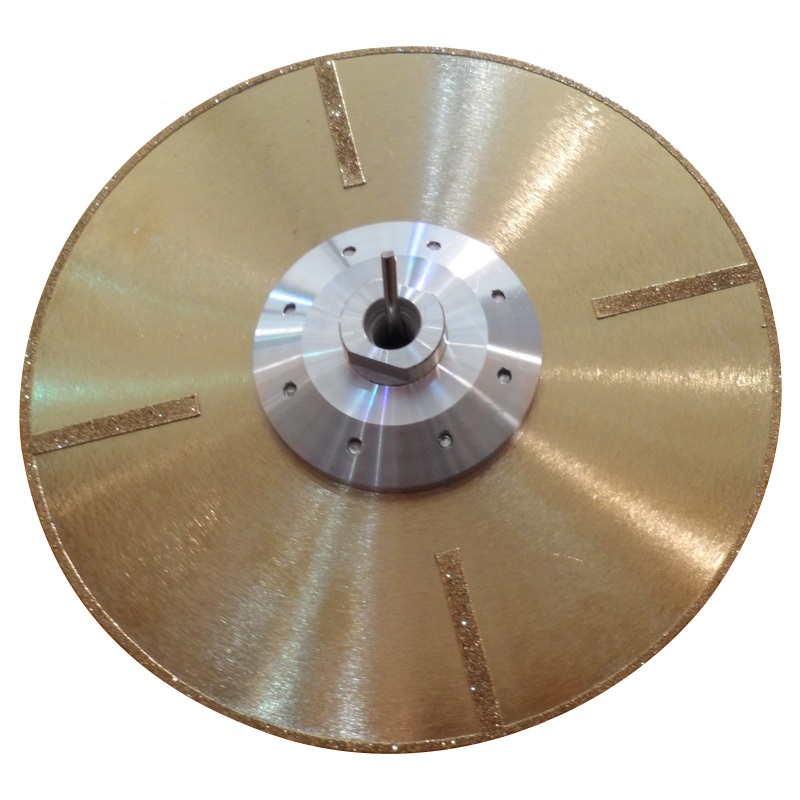

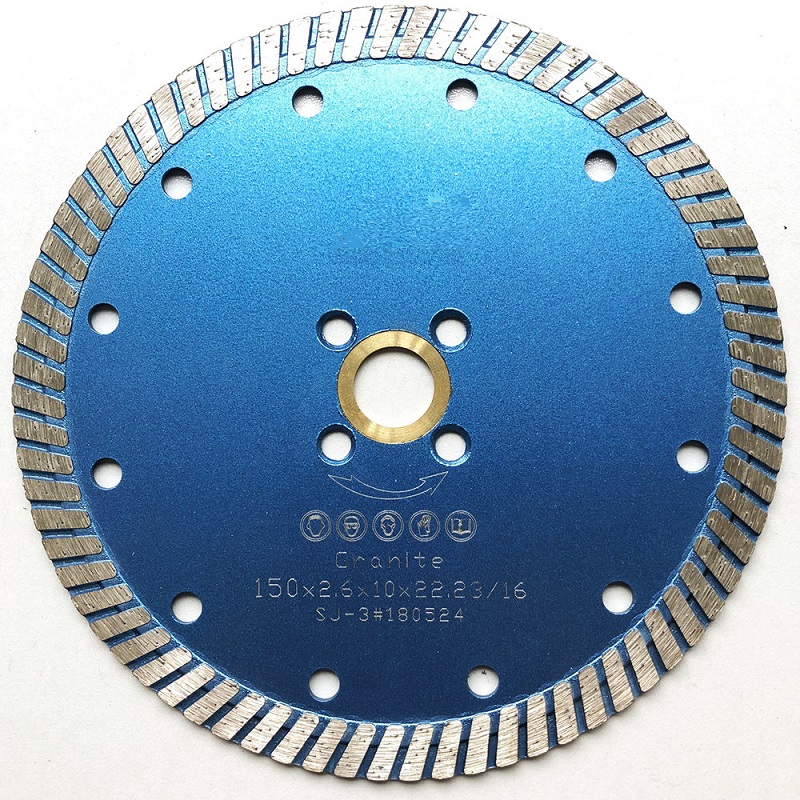

Laser Welded Circular Diamond Saw Blade

Features

1. Laser Welded Segments: The diamond segments of a laser welded circular diamond saw blade are precisely and securely welded to the core using advanced laser technology. This bonding method ensures superior strength, stability, and durability.

2. High-Quality Diamond Grit: The diamond segments of the saw blade are embedded with high-quality industrial-grade diamond grit. This allows for fast and efficient cutting through a variety of materials, including concrete, asphalt, stone, and more.

3. Heat Resistance: The laser welded bond provides excellent heat resistance, allowing the saw blade to withstand high temperatures generated during cutting. This prevents overheating and extends the blade's lifespan.

4. Precise and Smooth Cutting: The laser-welded diamond segments are designed with precision and accuracy to deliver clean and smooth cuts. This feature ensures professional-quality results and minimizes the need for additional finishing or polishing.

5. Reduced Vibration and Noise: The laser welding technique used in manufacturing the circular diamond saw blade helps to reduce vibration and noise during operation. This leads to a more comfortable and user-friendly cutting experience.

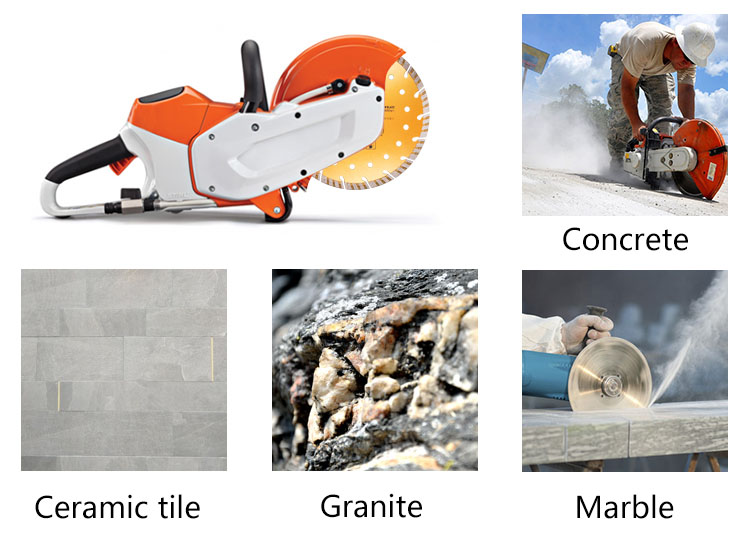

6. Versatility: Laser welded circular diamond saw blades are versatile and suitable for a wide range of cutting applications. They can be used to cut various materials, including concrete, masonry, brick, tile, granite, and more. This versatility makes them a valuable tool for different construction and renovation projects.

7. Long Lifespan: The laser welded bond provides exceptional strength, enhancing the overall durability and lifespan of the saw blade. This allows for extended use without compromising the cutting performance.

8. Fast Cutting Speed: The high-quality diamond grit and precise design of the laser welded circular diamond saw blade ensure fast and efficient cutting. This saves time and increases productivity on the job site.

9. Compatibility with Wet and Dry Cutting: Laser welded circular diamond saw blades are designed to be used for both wet and dry cutting applications. This flexibility allows users to choose the most suitable cutting method for their specific needs and working conditions.

10. Compatibility with Various Power Tools: Laser welded circular diamond saw blades are compatible with a range of power tools, including circular saws, angle grinders, and concrete saws. This makes it easy to use and provides flexibility in tool selection.

Product Testing

production site