Diamond Saw Blades: A Complete Guide to Features, Advantages, and Technical Details

Key Features of Diamond Saw Blades

The performance of a diamond saw blade hinges on its unique design and construction. Here are the critical features that define its capabilities:

1. Diamond Grit: The Cutting Powerhouse

At the core of every diamond saw blade is its diamond grit—small, industrial-grade diamonds embedded in the blade’s edge. The characteristics of this grit directly impact cutting speed and precision:

- Grit Size: Measured in mesh (e.g., 30/40, 50/60), smaller grits (higher numbers like 120/140) produce smoother cuts, ideal for polishing or finishing. Larger grits (30/40) cut faster but leave a rougher surface, suited for heavy-duty tasks like breaking through concrete.

- Diamond Concentration: Refers to the number of diamonds per cubic centimeter of the blade’s segment. A concentration of 100 (the standard) means 4.4 carats of diamonds per segment. Higher concentrations (120–150) are better for dense materials like granite, while lower concentrations (75–80) work for softer materials like asphalt.

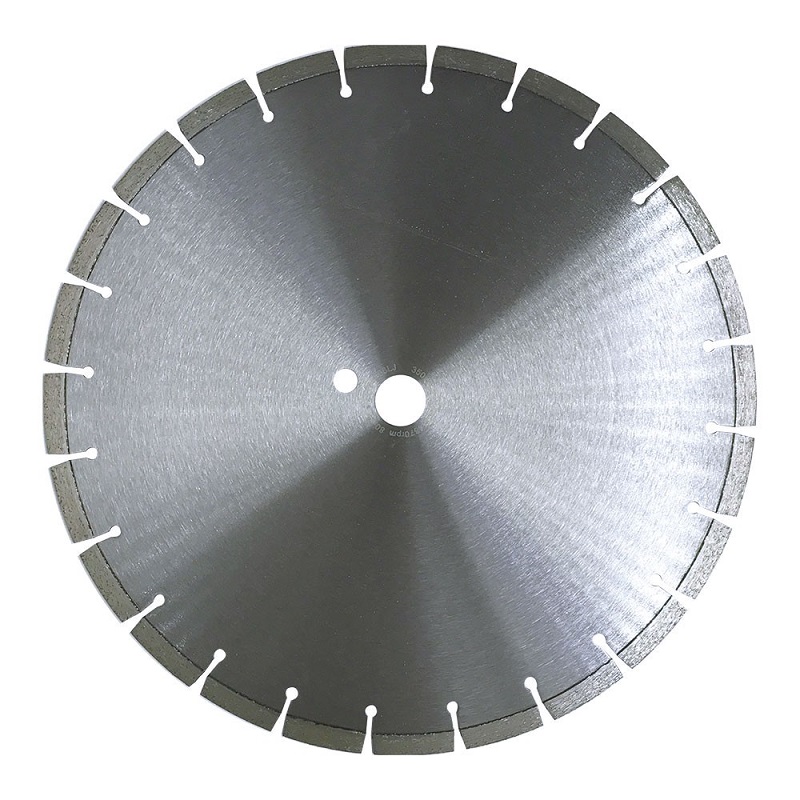

2. Blade Segments and Bond

Diamond blades are not solid; they consist of segments (the cutting edges) separated by gaps (called gullets) that remove debris. The segment’s bond— the material holding the diamonds in place—determines the blade’s durability and speed:

- Soft Bond: Designed for hard materials (e.g., granite, glass). The bond wears away quickly, exposing fresh diamonds to maintain cutting efficiency.

- Hard Bond: Ideal for soft, abrasive materials (e.g., concrete, brick). It resists wear, ensuring the diamonds stay embedded longer.

- Medium Bond: A versatile option for mixed materials like limestone or marble, balancing speed and longevity.

Segments also vary in shape: turbo segments (with curved edges) cut faster, while segmented blades (straight edges) excel at heavy debris removal.

3. Blade Diameter and Arbor Size

Diamond saw blades come in a range of diameters (4 inches to 48 inches) to fit different tools:

- Small Diameters (4–14 inches): Used with handheld tools like angle grinders or circular saws for precision cuts in tile or metal.

- Large Diameters (16–48 inches): Mounted on walk-behind saws or floor saws for cutting concrete slabs, roads, or large stone blocks.

The arbor size (the hole in the center of the blade) must match the tool’s spindle. Common sizes include 5/8 inch, 1 inch, and 20mm, with adapters available for mismatched sizes.

Advantages of Using Diamond Saw Blades

Diamond saw blades outperform traditional blades in nearly every metric, making them the top choice for tough cutting tasks:

1. Unmatched Cutting Speed and Efficiency

Diamonds’ hardness allows these blades to slice through hard materials like concrete or granite much faster than carbide or steel blades. This reduces project time—critical for professionals working on tight deadlines.

2. Longevity and Cost Savings

While diamond blades have a higher upfront cost, their durability far outweighs cheaper alternatives. A single diamond blade can cut hundreds of feet of concrete, whereas a carbide blade might need replacement after just a few feet. This longevity lowers long-term expenses.

3. Versatility Across Materials

From ceramic tile to reinforced concrete, diamond blades handle a wide range of materials without sacrificing performance. This versatility eliminates the need for multiple blades, simplifying tool kits and reducing setup time.

4. Precision and Clean Cuts

The controlled wear of diamond grit ensures smooth, accurate cuts, minimizing chipping or cracking—essential for tasks like installing tile or cutting stone for countertops. This precision reduces waste and the need for post-cutting polishing.

Technical Tips for Using and Maintaining Diamond Saw Blades

To maximize performance and safety, follow these technical guidelines:

1. Operating Speed (RPM)

Every diamond blade has a maximum safe RPM (rotations per minute) specified by the manufacturer. Exceeding this can cause the blade to overheat, warp, or even shatter. Match the blade’s RPM to your tool:

- Handheld grinders: 8,000–12,000 RPM (for small blades).

- Walk-behind saws: 2,000–5,000 RPM (for large blades).

Always check the tool’s manual and the blade’s label for compatibility.

2. Cooling and Lubrication

Diamond blades generate intense heat during cutting, which can damage both the blade and the material. Use water cooling (for wet cutting) or dust extraction (for dry cutting) to prevent overheating:

- Wet Cutting: Attaches a water hose to the tool, spraying a steady stream on the blade to reduce friction and dust. Ideal for indoor projects or when precision is key.

- Dry Cutting: Uses a vacuum system to remove debris. Suitable for outdoor tasks but requires blades specifically designed for dry use (marked “dry cut”).

3. Proper Blade Break-In

New diamond blades need a break-in period to ensure even wear. Start by cutting a soft material (like asphalt) at half speed for 30–60 seconds, gradually increasing to full speed. This prevents uneven diamond exposure and extends blade life.

4. Maintenance and Storage

- Clean After Use: Remove debris from segments with a wire brush to prevent clogging, which reduces cutting efficiency.

- Store Flat: Lay blades flat or hang them vertically to avoid warping. Never stack heavy objects on top of them.

- Inspect Regularly: Check for cracked segments, loose diamonds, or warping. Damaged blades should be replaced immediately to avoid accidents.

Choosing the Right Diamond Saw Blade for Your Project

Selecting the correct blade depends on the material and tool:

- Concrete or Masonry: Choose a segmented blade with a hard bond and 30/40 grit for fast cutting.

- Tile or Glass: Opt for a continuous rim blade with fine grit (120/140) and a soft bond for smooth, chip-free cuts.

- Stone (Granite/Marble): Use a turbo segment blade with high diamond concentration (120) and a medium bond.

- Metal: Select a dry-cut blade with a hard bond, designed to cut through rebar or steel.

Post time: Aug-16-2025