Preminium Quality Tungsten Carbide Square End Mill for Super Hard Metal

Features

1. Enhanced hardness and durability: The tungsten carbide material used in the end mill provides excellent hardness and durability, allowing it to withstand high-speed machining operations and extended tool life.

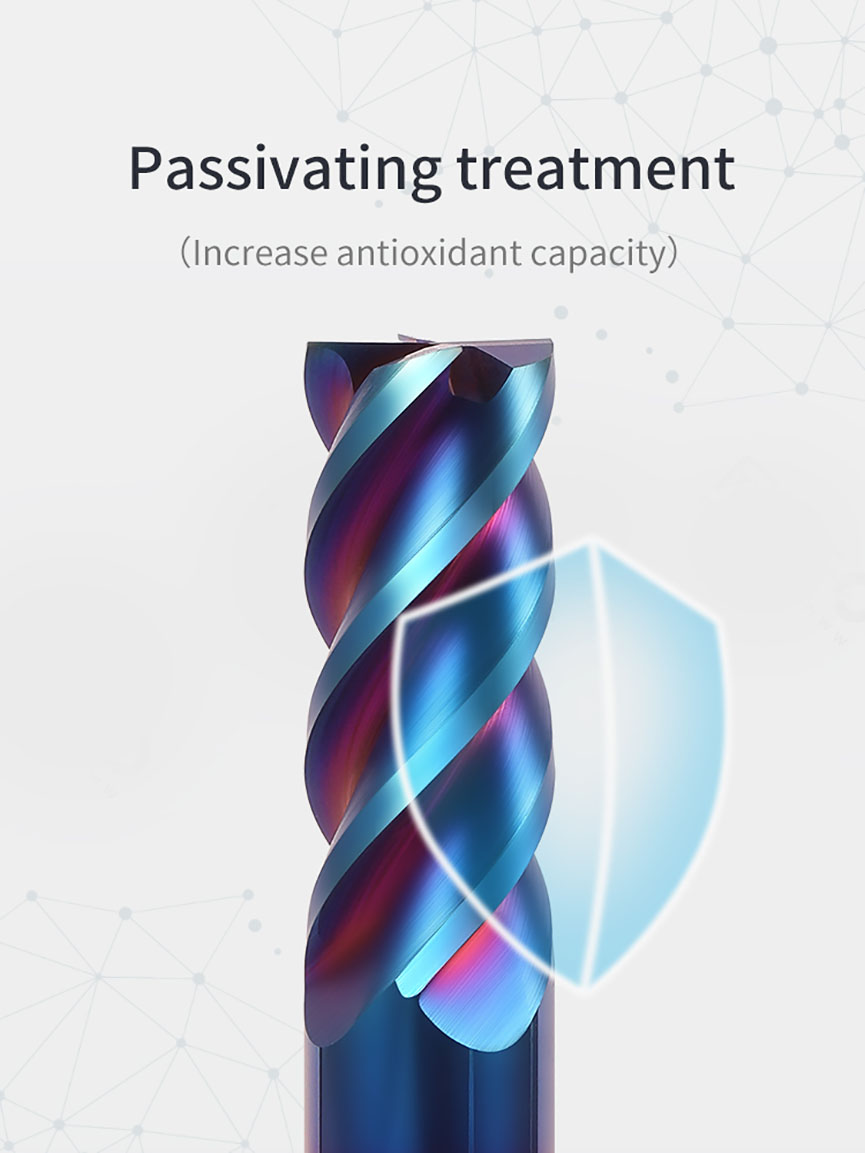

2. Nano blue coating: The nano blue coating is a thin, smooth film applied to the end mill's surface using advanced coating technologies. This coating enhances the tool's performance by reducing friction and heat generation during cutting, improving chip evacuation, and resisting wear and corrosion.

3. Increased cutting speed: The nano blue coating reduces the friction between the end mill and the workpiece, allowing for higher cutting speeds. This leads to improved productivity and efficiency in machining operations.

4. Superior heat resistance: The nano blue coating enhances the end mill's heat resistance, enabling it to withstand high temperatures generated during cutting. This minimizes tool deformation and prolongs the tool's lifespan.

5. Excellent wear resistance: The nano blue coating provides exceptional wear resistance, reducing the tool's wear rate and extending its service life. This results in a consistent cutting performance and reduced downtime for tool changes.

6. Improved chip evacuation: The smooth surface of the nano blue coating promotes better chip evacuation, preventing chip build-up and reducing the risk of tool breakage or damage.

7. Precise and accurate cutting: The combination of the high-quality tungsten carbide material and the nano blue coating allows for precise and accurate cutting, resulting in clean and smooth finishes on the workpiece.

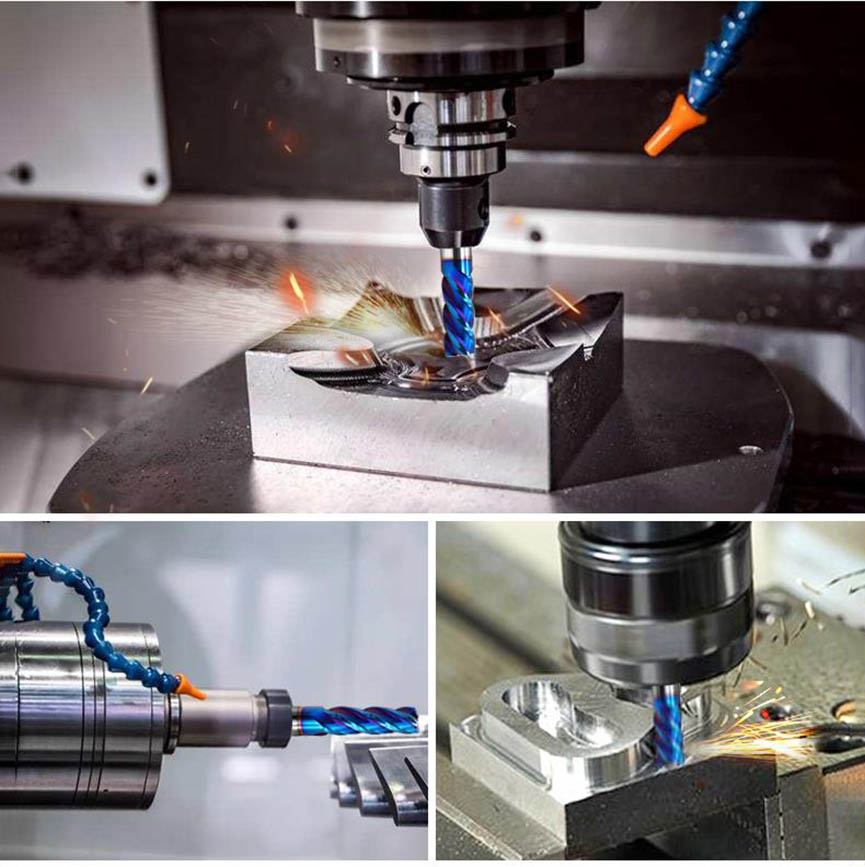

8. Versatility: Tungsten carbide square end mills with a nano blue coating can be used for a wide range of milling operations, including roughing, finishing, contouring, and profiling in various materials such as steel, stainless steel, aluminum, and more.

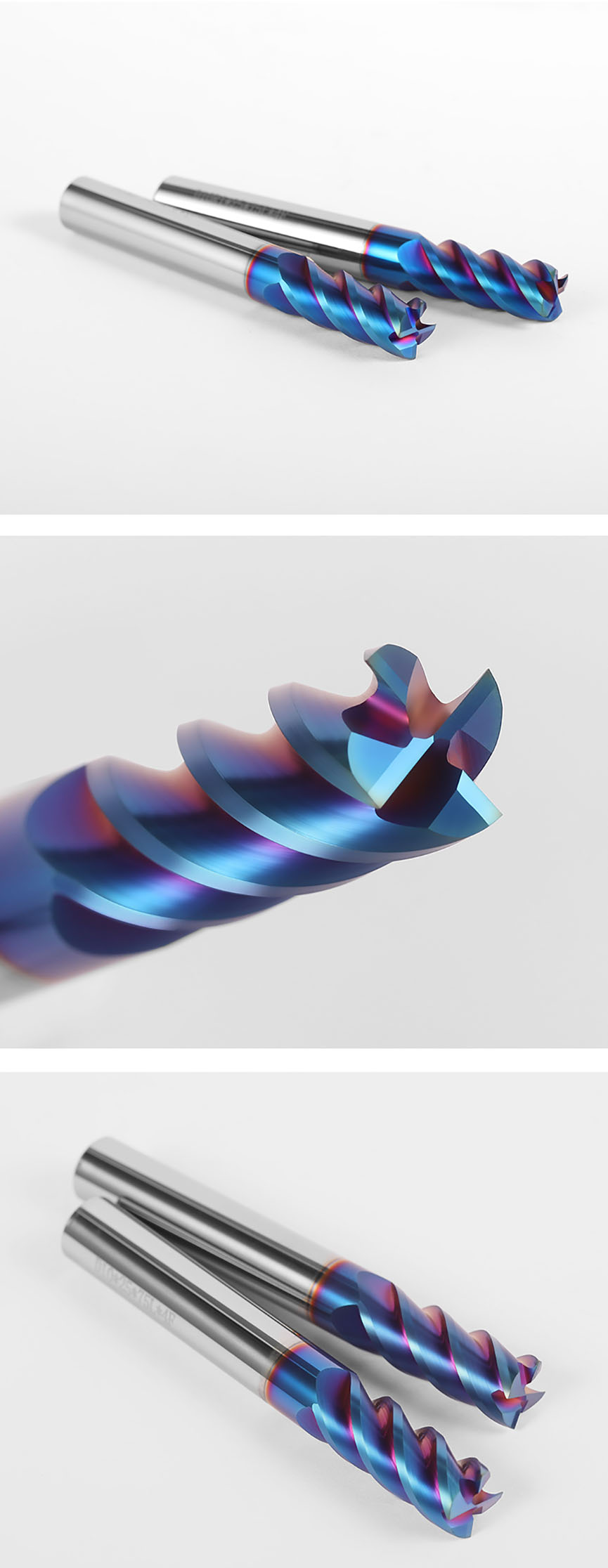

preminium quality tungsten carbide square end mill detail

Product detail diagram

Advantages

1. Enhanced tool life: The combination of high-quality tungsten carbide and the nano blue coating significantly increases the end mill's tool life compared to uncoated versions. This results in reduced tooling costs and improved productivity

2. Improved cutting speed: The nano blue coating reduces friction and heat generation during cutting, allowing for higher cutting speeds. This helps to boost machining efficiency and reduce cycle times.

3. Increased wear resistance: The nano blue coating enhances the end mill's wear resistance, providing protection against abrasion and extending the tool's lifespan. This means less frequent tool changes and reduced downtime.

4. Superior surface finish: The nano blue coating minimizes built-up edge and reduces cutting forces, resulting in a smoother and more precise surface finish on the workpiece. This is particularly beneficial for applications requiring high surface quality.

5. Chip evacuation and coolant efficiency: The nano blue coating improves chip flow and coolant distribution, preventing chip clogging and ensuring effective heat dissipation. This helps to maintain excellent cutting performance and reduce the risk of tool failure.

6. Corrosion resistance: The nano blue coating provides a protective barrier against corrosion, extending the end mill's durability and minimizing the possibility of premature failure due to chemical degradation.

7. Versatility in machining applications: Premium quality tungsten carbide square end mills with a nano blue coating can be used in various materials, including stainless steel, hardened steels, cast iron, and non-ferrous metals. They are suitable for roughing, finishing, and contouring operations, offering flexibility in machining applications.

8. Improved tool stability: The nano blue coating helps to reduce vibration and improve tool stability during cutting, resulting in higher process reliability and improved dimensional accuracy.

9. Environmental benefits: The use of a high-performance end mill with a nano blue coating can reduce cutting parameters, such as cutting forces and cutting speed. This can lead to energy savings and lower resource consumption, contributing to a greener and more sustainable machining process.

| Blade diameter (mm) | Blade length (mm) | Full(mm) | Shank (mm) |

| 1.0 | 3 | 50 | 4 |

| 1.5 | 4 | 50 | 4 |

| 2.0 | 6 | 50 | 4 |

| 2.5 | 7 | 50 | 4 |

| 3.0 | 8 | 50 | 4 |

| 3.5 | 10 | 50 | 4 |

| 4.0 | 11 | 50 | 4 |

| 1.0 | 3 | 50 | 6 |

| 1.5 | 4 | 50 | 6 |

| 2.0 | 6 | 50 | 6 |

| 2.5 | 7 | 50 | 6 |

| 3.0 | 8 | 50 | 6 |

| 3.5 | 10 | 50 | 6 |

| 4.0 | 11 | 50 | 6 |

| 4.5 | 13 | 50 | 6 |

| 5.0 | 13 | 50 | 6 |

| 5.5 | 13 | 50 | 6 |

| 6.0 | 15 | 50 | 6 |

| 6.5 | 17 | 60 | 8 |

| 7.0 | 17 | 60 | 8 |

| 7.5 | 17 | 60 | 8 |

| 8.0 | 20 | 60 | 8 |

| 8.5 | 23 | 75 | 10 |

| 9.0 | 23 | 75 | 10 |

| 9.5 | 25 | 75 | 10 |

| 10.0 | 25 | 75 | 10 |

| 10.5 | 25 | 75 | 12 |

| 11.0 | 28 | 75 | 12 |

| 11.5 | 28 | 75 | 12 |

| 12.0 | 30 | 75 | 12 |

| 13.0 | 45 | 100 | 14 |

| 14.0 | 45 | 100 | 14 |

| 15.0 | 45 | 100 | 16 |

| 16.0 | 45 | 100 | 16 |

| 17.0 | 45 | 100 | 18 |

| 18.0 | 45 | 100 | 18 |

| 19.0 | 45 | 100 | 20 |

| 20.0 | 45 | 100 | 20 |

| 22.0 | 45 | 100 | 25 |

| 25.0 | 45 | 100 | 25 |