Roma Type vacuum brazed Diamond grinding Profile Wheel

Advantages

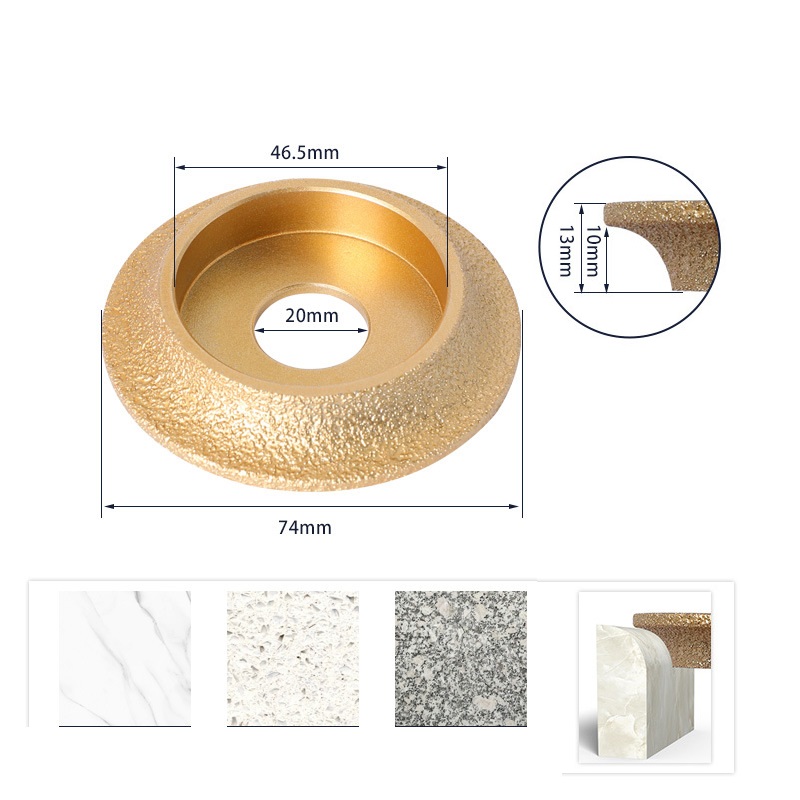

1. These grinding wheels are extremely versatile and can be used to grind and shape a variety of materials, including natural stone, engineered stone, concrete and ceramics. This versatility makes it suitable for a wide range of applications in industries including construction, masonry and stone manufacturing.

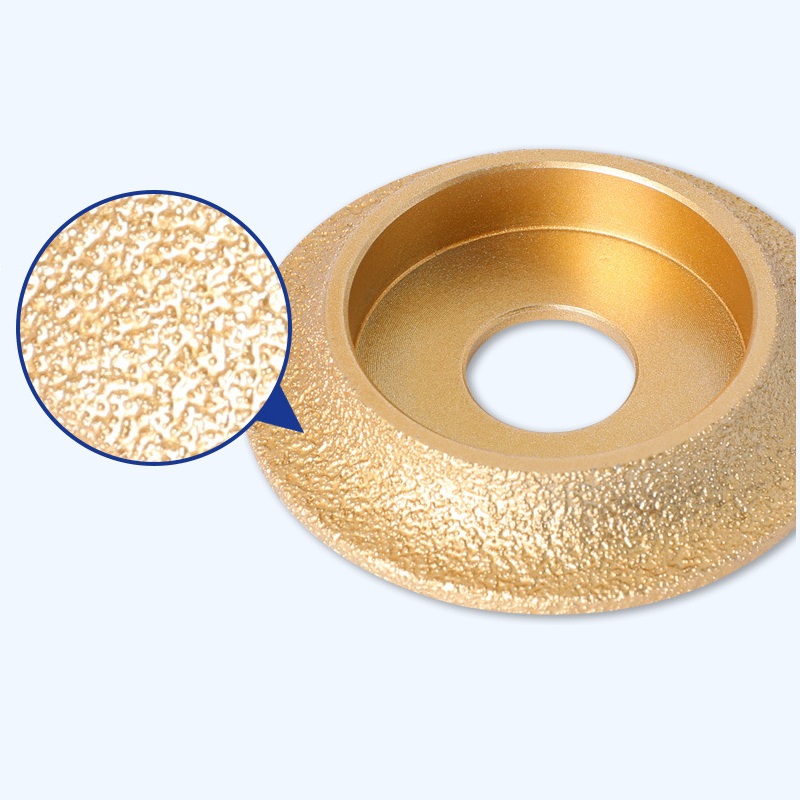

2.The vacuum brazing process used to manufacture these wheels creates a strong and long-lasting bond between the diamond particles and the wheel base material. This ensures long-lasting performance and excellent retention of the diamond grit, thus reducing the frequency of grinding wheel changes.

3.Vacuum-brazed diamond particles adhere firmly to the grinding wheel, providing an aggressive cutting action for efficient material removal and shaping. This feature is especially useful when working with hard or dense materials that require precision and consistency.

4.Vacuum-brazed diamond particles provide a strong bond with the grinding wheel, helping to reduce the risk of chipping or falling off during use.

5.Vacuum brazing design effectively dissipates heat during the grinding process to prevent overheating and extend the service life of the grinding wheel.

6.The profile shape of these grinding wheels combined with the precise distribution of diamond particles allows for smooth and precise grinding, resulting in a high-quality finish and precise profile shape.

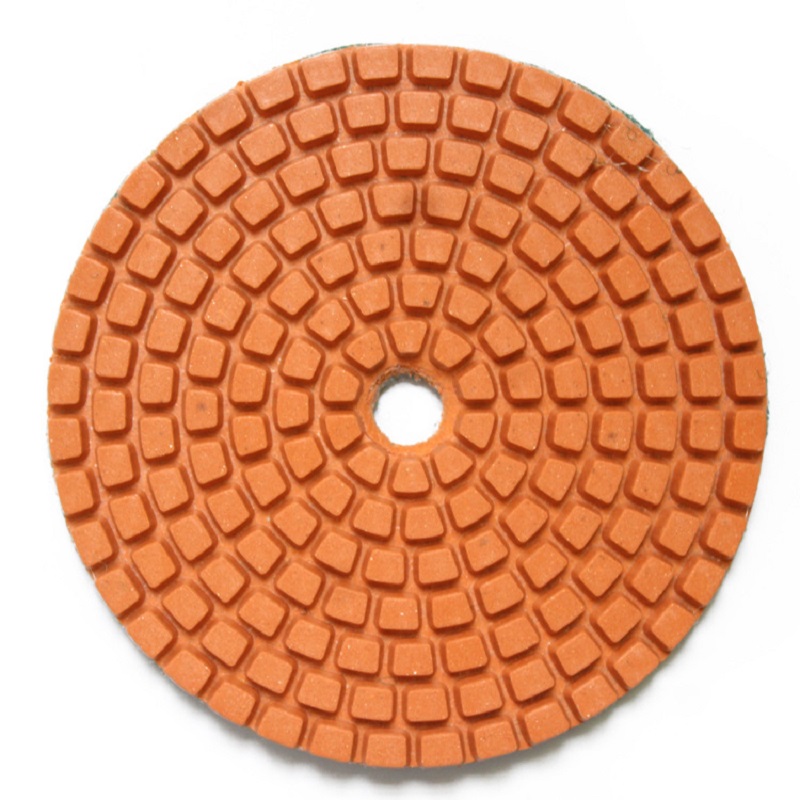

7.Compared to other types of grinding wheels, vacuum brazed diamond grinding profile wheels are less prone to clogging due to their open structure and efficient debris removal during grinding.

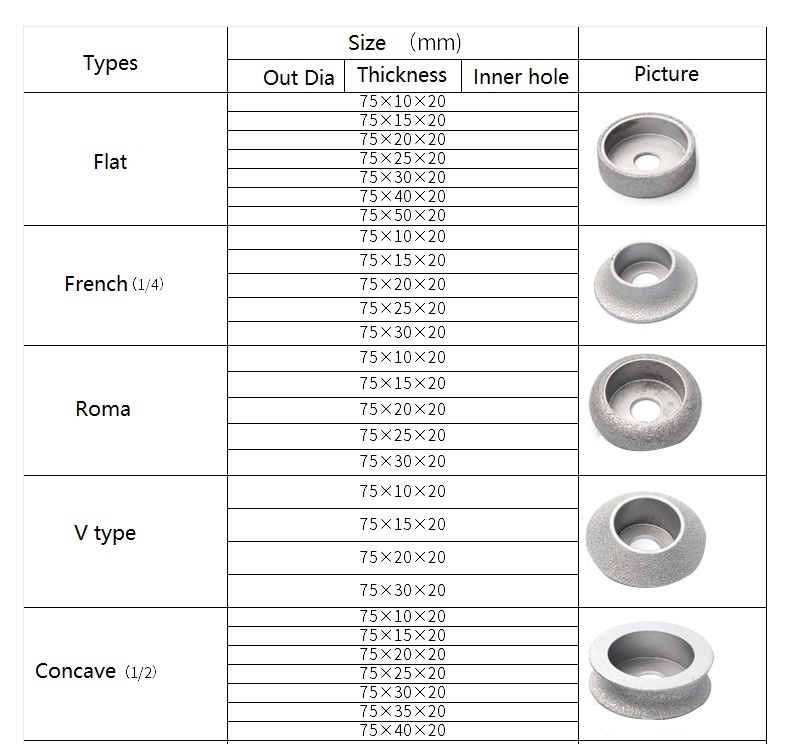

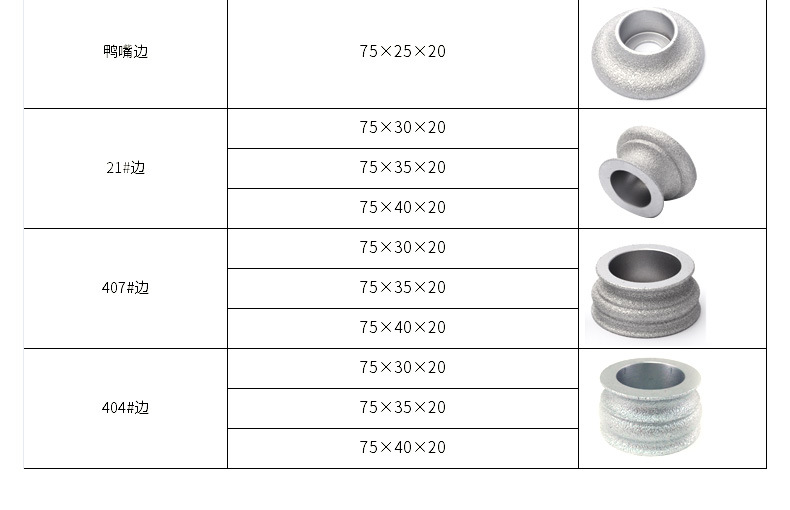

PRODUCT TYPES

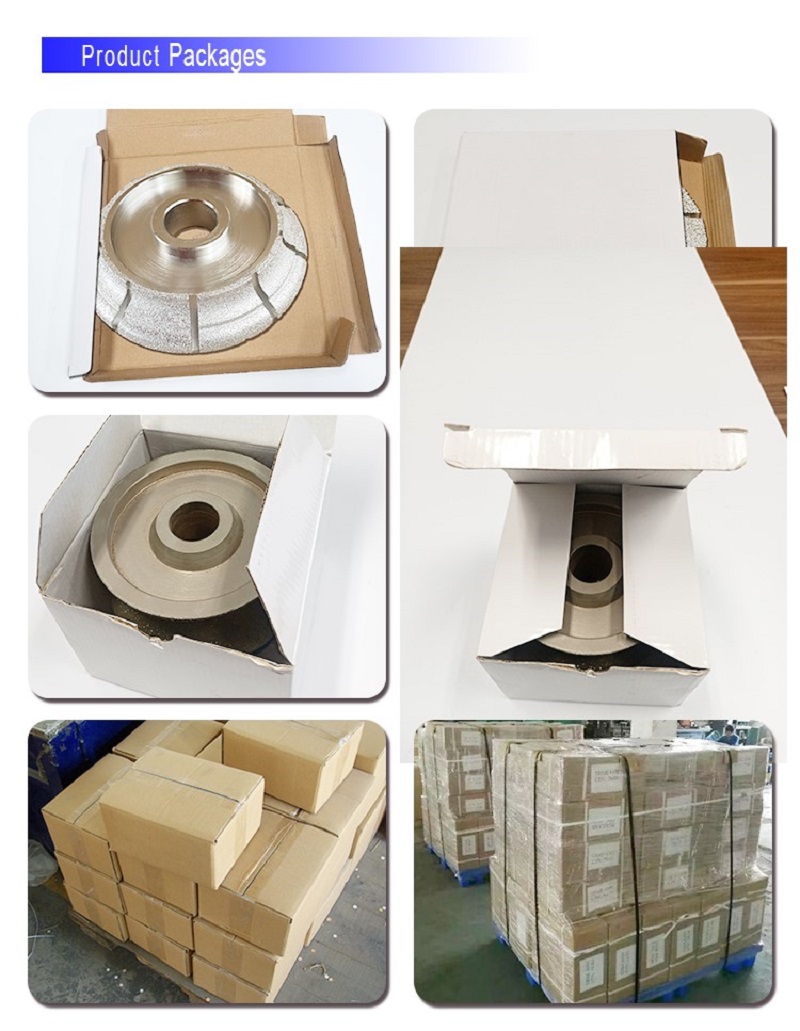

package