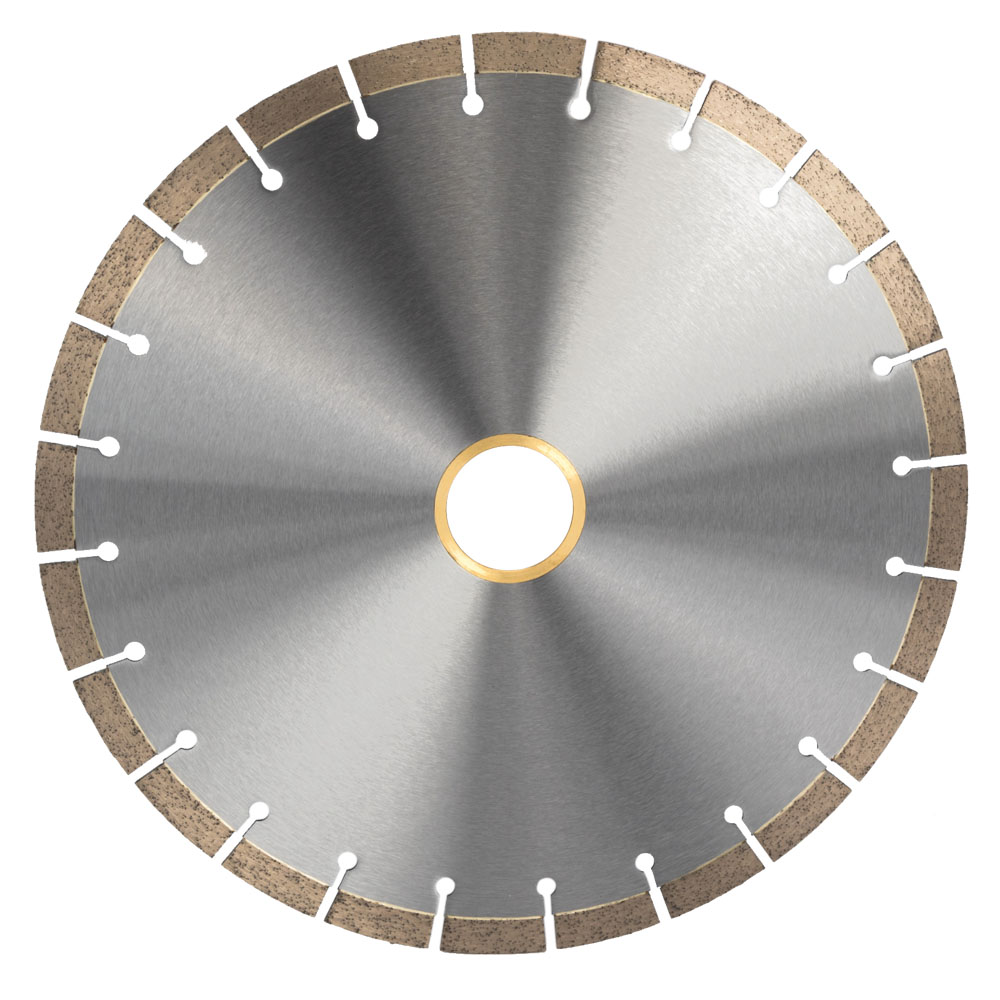

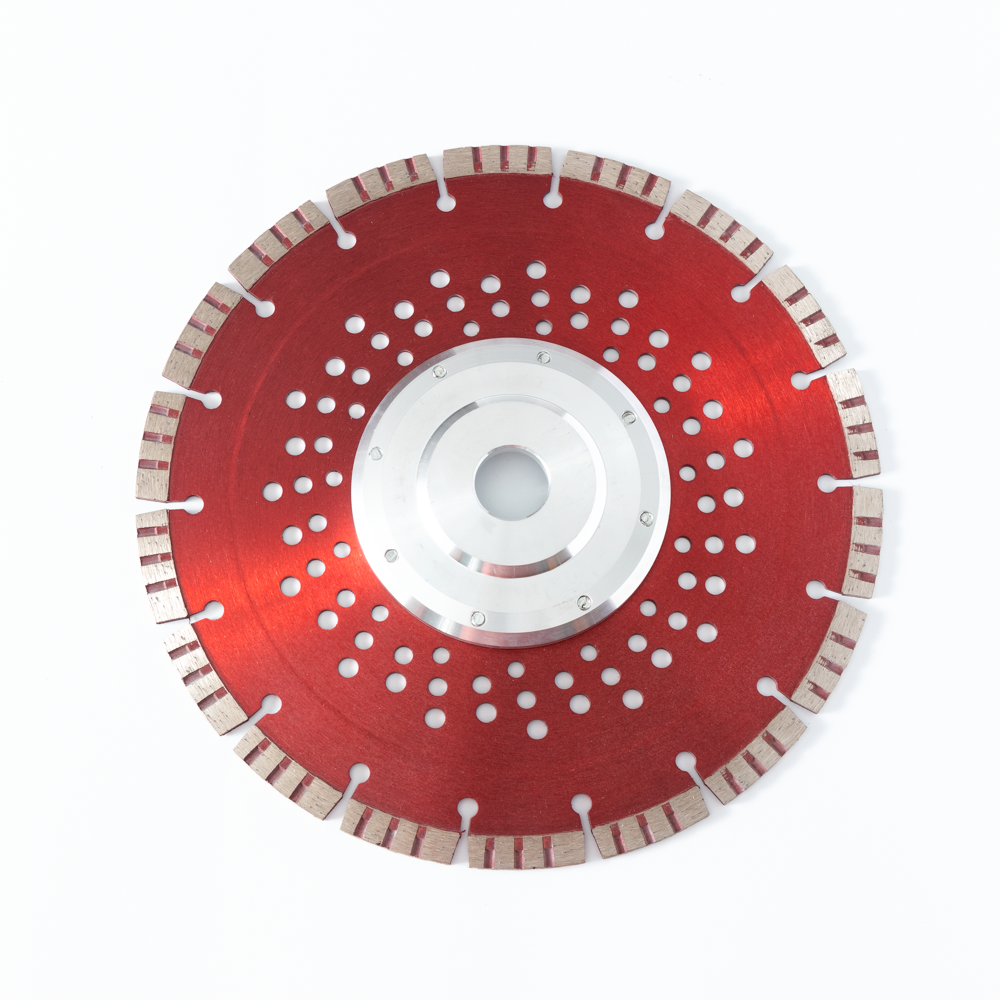

Sintered Diamond circular saw Blade for cutting asphalt

advantages

1.Sintered diamond saw blades are known for their exceptional durability and resiliency, making them ideal for the abrasive nature of asphalt cutting. The sintering process creates a strong bond between the diamond tip and blade, ensuring long-lasting performance.

2.Sintered diamond saw blades are designed to cut asphalt efficiently, resulting in fast, smooth cutting operations. This helps increase productivity and reduce labor costs.

3.The design of sintered diamond blades often includes features that promote efficient heat dissipation during the cutting process. This helps prevent the blade from overheating, reduces the risk of warping or damage, and extends the life of the blade.

4.While primarily used for cutting asphalt, sintered diamond saw blades are also effective at cutting other abrasive materials such as fresh concrete, bricks and masonry, providing versatility to contractors and construction professionals.

5.Sintered diamond tips help minimize chipping, ensuring clean, precise cuts resulting in a high-quality finished surface with minimal post-processing requirements.

6.Sintered diamond blades typically require less maintenance and blade replacement frequency than some other blade types, helping to reduce overall operating costs and downtime.

7.The long life and high efficiency of sintered diamond saw blades make them a cost-effective choice for asphalt cutting, providing a good balance between initial investment and long-term performance.

Product Testing

FACTORY SITE

| Diameter(mm) | Segment Length(mm) | Segment Width(mm) | Segment Height(mm) | Number |

| 200 | 40 | 3.2 | 10 | 14 |

| 250 | 40 | 3.2 | 10 | 17 |

| 300 | 40 | 3.2 | 10 | 21 |

| 350 | 40 | 3.2 | 10 | 24 |

| 400 | 40 | 3.6 | 10 | 28 |

| 450 | 40 | 4.0 | 10 | 32 |

| 500 | 40 | 4.0 | 10 | 36 |

| 550 | 40 | 4.6 | 10 | 40 |

| 600 | 40 | 4.6 | 10 | 42 |

| 700 | 40 | 5.0 | 10 | 52 |

| 750 | 40 | 5.5 | 10 | 56 |

| 800 | 40 | 5.5 | 10 | 46 |