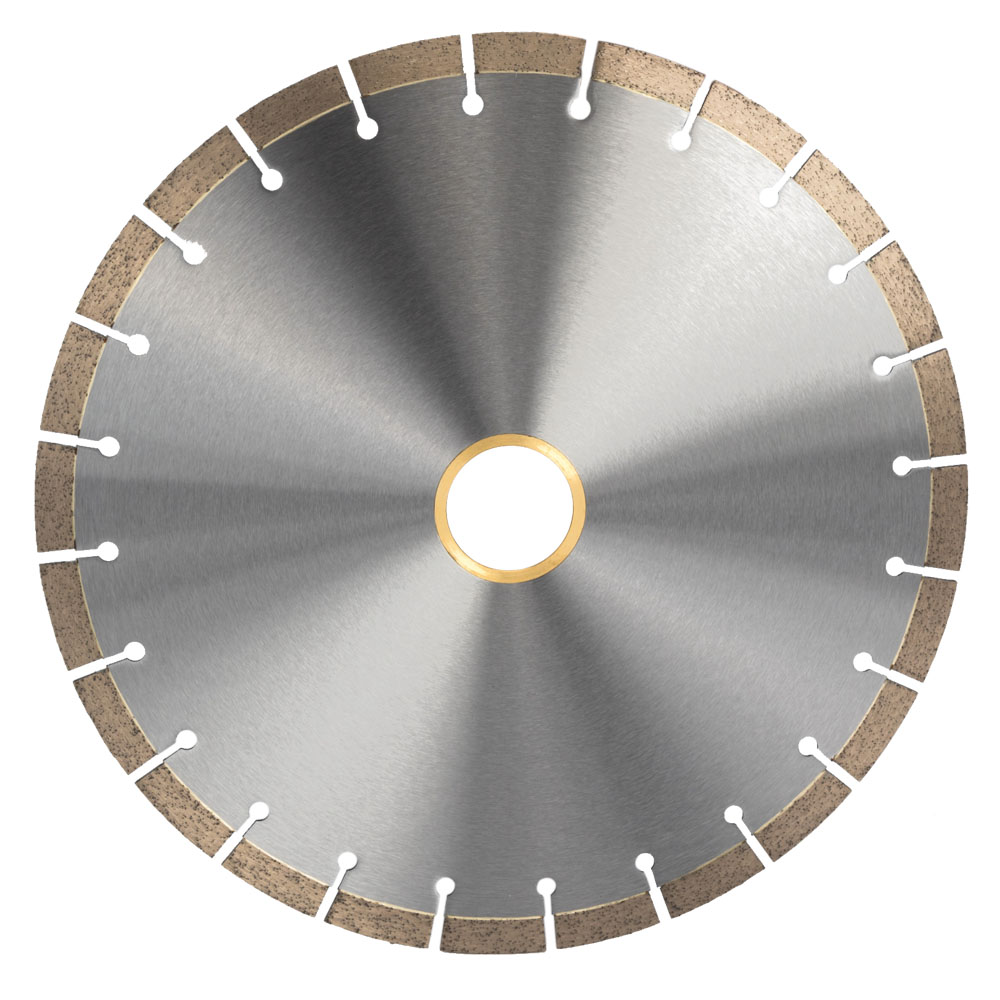

Staggered Segments Diamond Grinding pad

Advantages

1Staggered segments create channels between segments for efficient removal of grinding dust and debris. This helps maintain a cleaner working environment and improves visibility during grinding.

2.The staggered arrangement of segments facilitates better airflow and cooling during grinding, which helps prevent the grinding pad and material being processed from overheating. This feature helps extend tool life and reduces the risk of thermal damage to the workpiece.

3.Staggered sections minimize chatter and vibration during grinding, resulting in smoother, more even grinding results. This improves the overall surface finish and reduces the risk of scratches or uneven wear marks.

4.The staggered configuration of segments helps distribute grinding pressure more evenly across the work surface, resulting in efficient material removal and more consistent grinding performance.

5.Staggered segments provide greater flexibility and adaptability to uneven surfaces and contours, allowing the pad to maintain better contact with the workpiece. This allows for more uniform material removal, especially on irregular or undulating surfaces.

6.The improved airflow, reduced heat build-up and more balanced pressure distribution provided by the staggered segments help extend the life of the diamond pad, thereby reducing replacement frequency and associated costs.

Overall, using staggered segments in diamond grinding pads results in improved dust removal, better heat dissipation, reduced vibration, enhanced material removal, better adaptability to different surface profiles, and longer tool life. These advantages make staggered sections a valuable feature for achieving efficient grinding results in a variety of applications.

APPLICATIONS

factory site