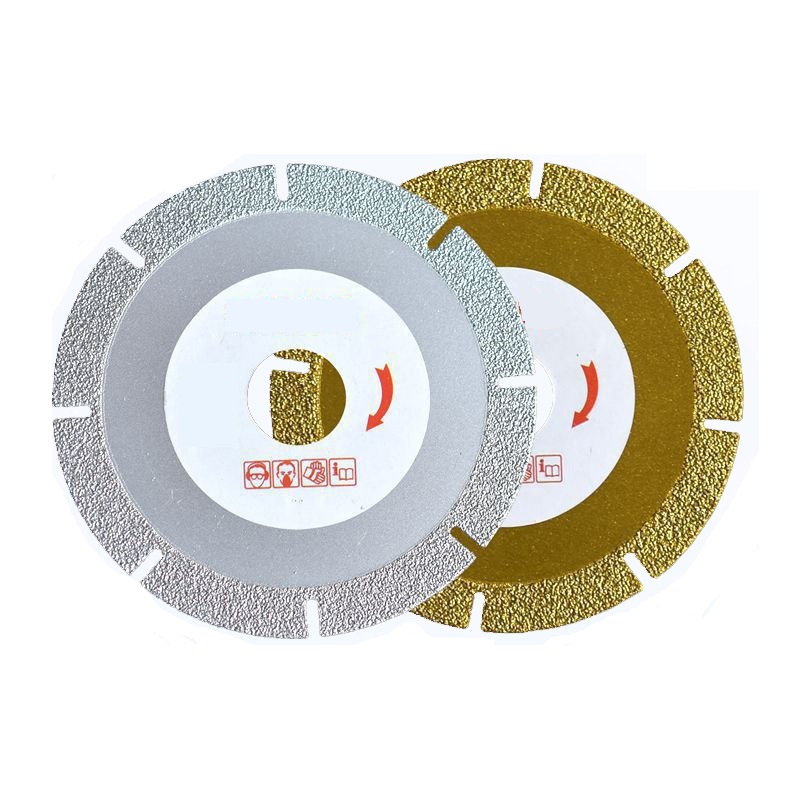

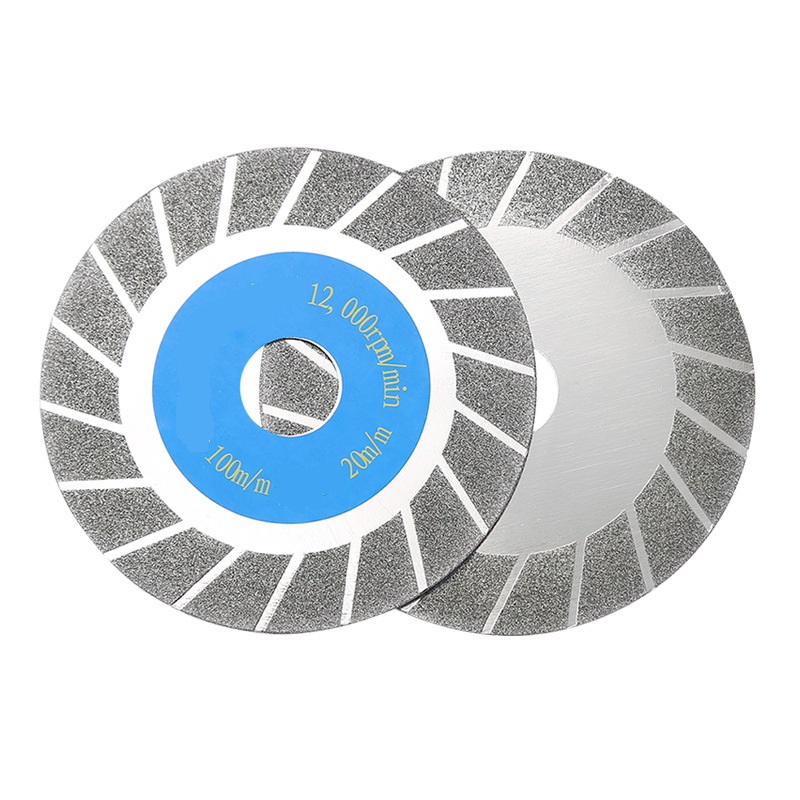

Super thin glass cutting blade

Features

Ultra-thin glass cutting blades are designed to cut glass precisely and minimize shattering. Some of the key features of these blades include:

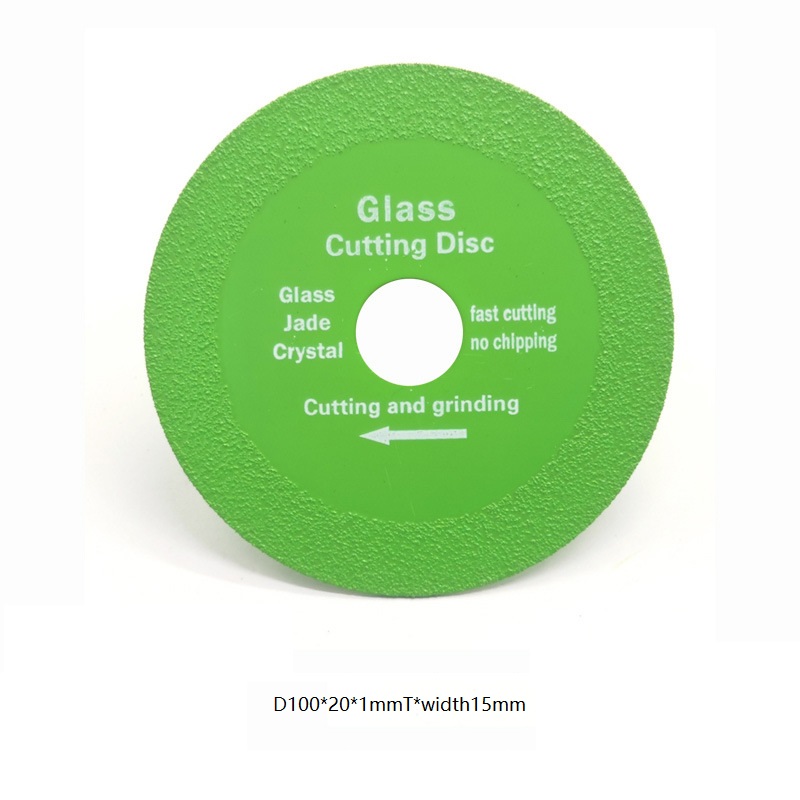

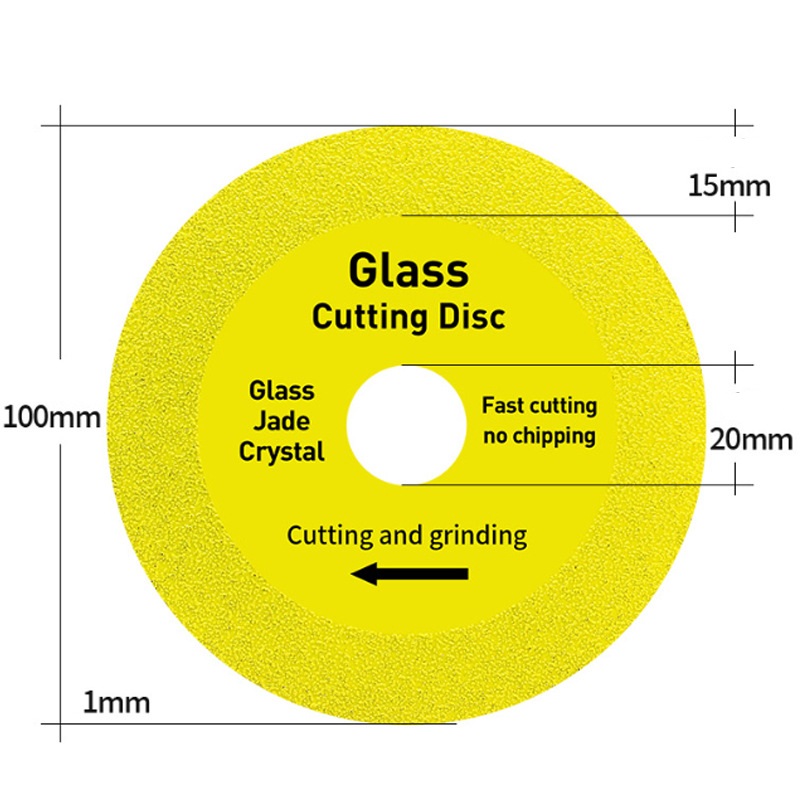

1. Ultra-thin glass cutting blades have an extremely thin profile, allowing for precise, clean cuts in glass materials.

2. These blades are typically made from diamond or carbide particles embedded in the cutting edge, providing superior hardness and durability for cutting glass.

3.The design of the blade ensures a smooth cutting action, reducing the risk of glass shattering or cracking during cutting.

4. The kerf width refers to the width of the material removed by the blade during cutting. Ultra-thin glass cutting blades feature minimal kerf width for precise cuts while minimizing material waste.

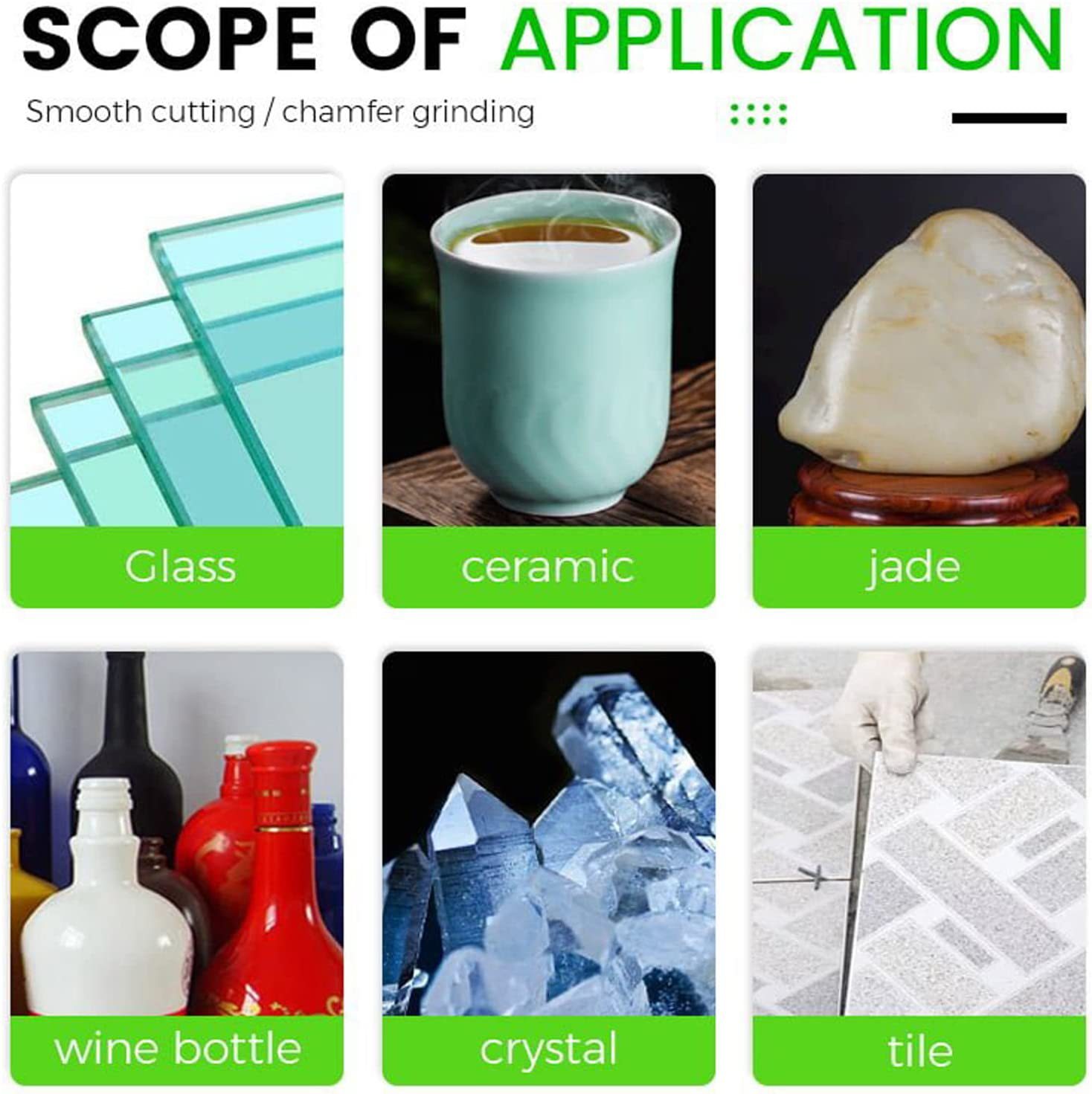

5. These blades are designed to be compatible with a variety of glass cutting tools, such as glass cutters, tile saws or rotary tools, allowing them to adapt to different cutting applications.

6. Some ultra-thin glass cutting blades are designed to effectively dissipate heat, reducing the risk of thermal damage to the glass during cutting.

7. Many high-quality glass cutting blades are coated with anti-corrosion materials to extend the life of the blade and maintain cutting performance over the long term.

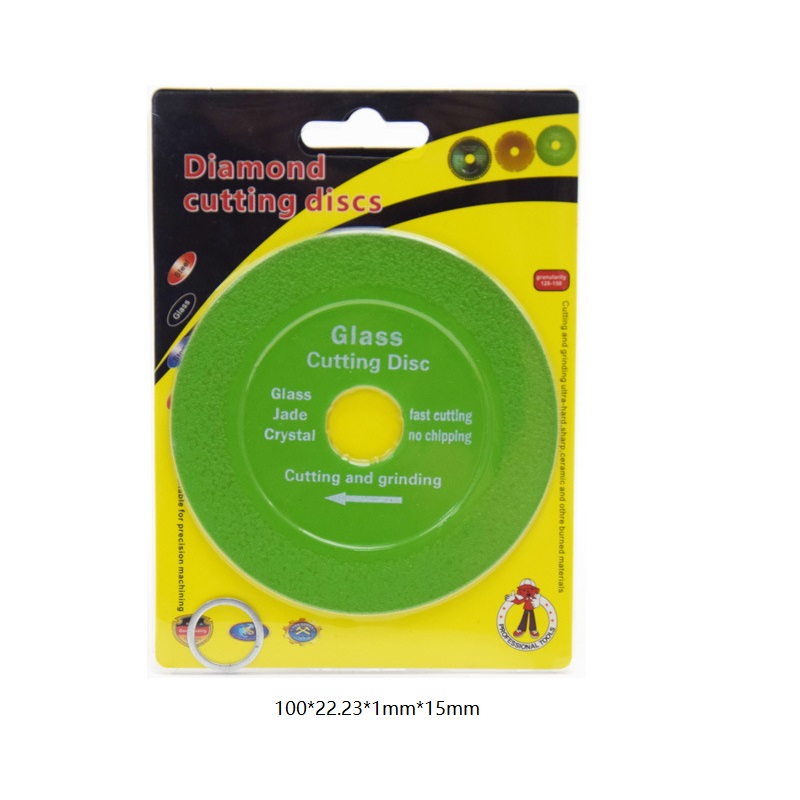

PRODUCT DETAIL