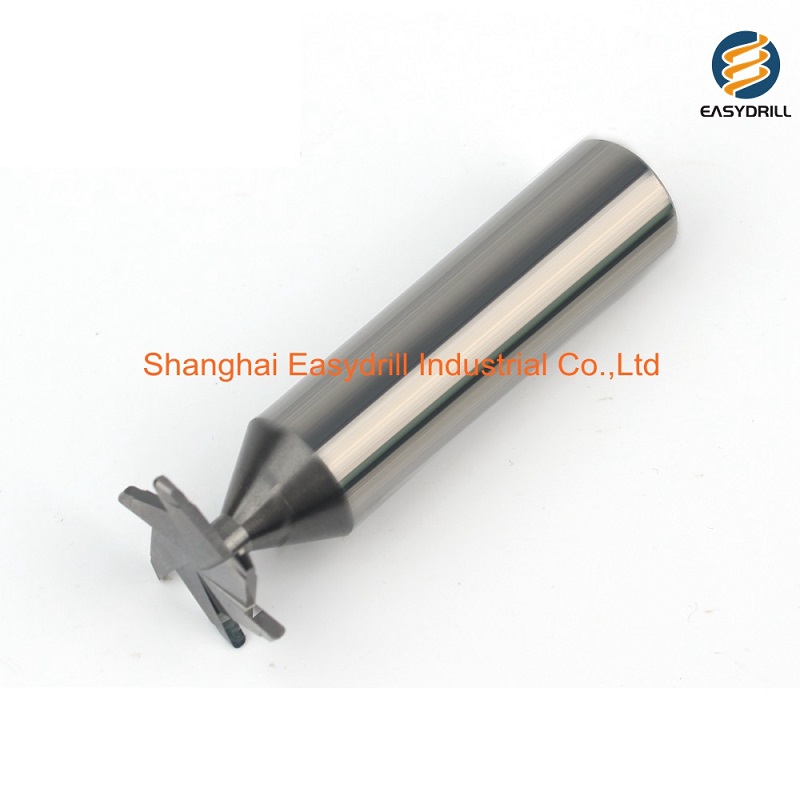

T type solid Carbide End Mill

Features

T-shaped solid carbide end mills are known for their high performance and precision cutting capabilities. Some of the key features of T-shaped solid carbide end mills include:

1. Solid carbide structure: T-shaped end mills are made of solid carbide, which has excellent hardness, wear resistance and heat resistance, thereby extending tool life and improving performance.

2. Variable Geometry: T-shaped end mills often have variable geometries that help with efficient chip evacuation, reduce cutting forces, and improve surface finish.

3. High helix angle: The high helix angle of T-type end mills can achieve efficient chip removal and improve cutting performance, especially in high-speed machining applications.

4. Center cutting design: Many T-type end mills are designed with center cutting function, allowing plunge cutting and ramping operations.

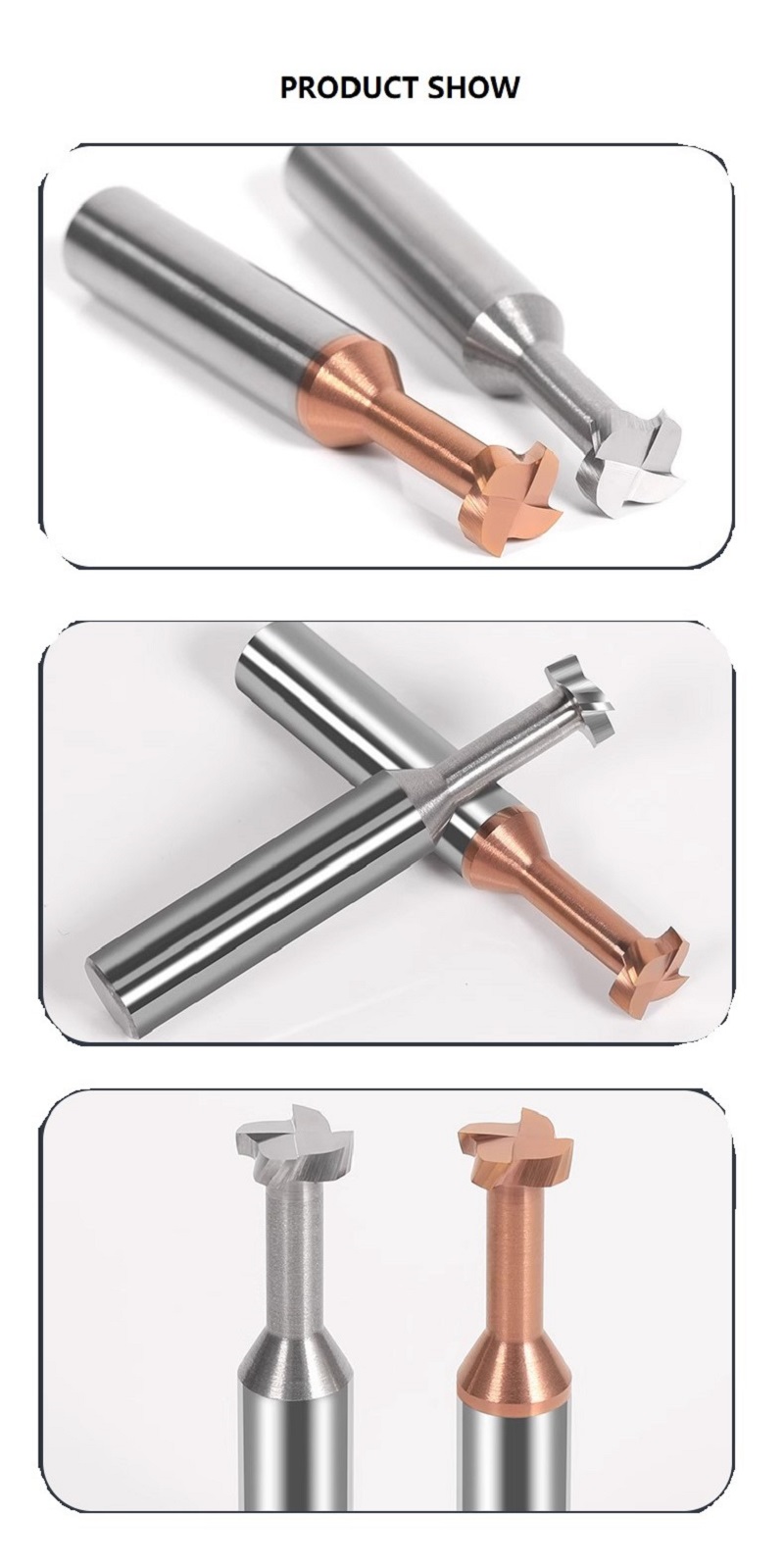

5. Multiple coating options: T-type end mills have multiple coating options, such as TiAlN, TiCN and AlTiN, which can enhance wear resistance, reduce friction and improve tool life.

6. Precision ground cutting edge: T-type end mills are manufactured with precision ground cutting edges to ensure precise and consistent cutting performance.

7. Various sizes and configurations: T-shaped end mills are available in a variety of sizes, groove lengths, and configurations to meet different machining requirements and applications.

PRODUCT SHOW

PRODUCT SHOW