TCT Annular Cutter for Metal Cutting

Features

1. Tungsten Carbide Tipped: TCT annular cutters have replaceable tips made of tungsten carbide. This material is known for its exceptional hardness and resistance to wear, making it suitable for cutting through tough and abrasive materials.

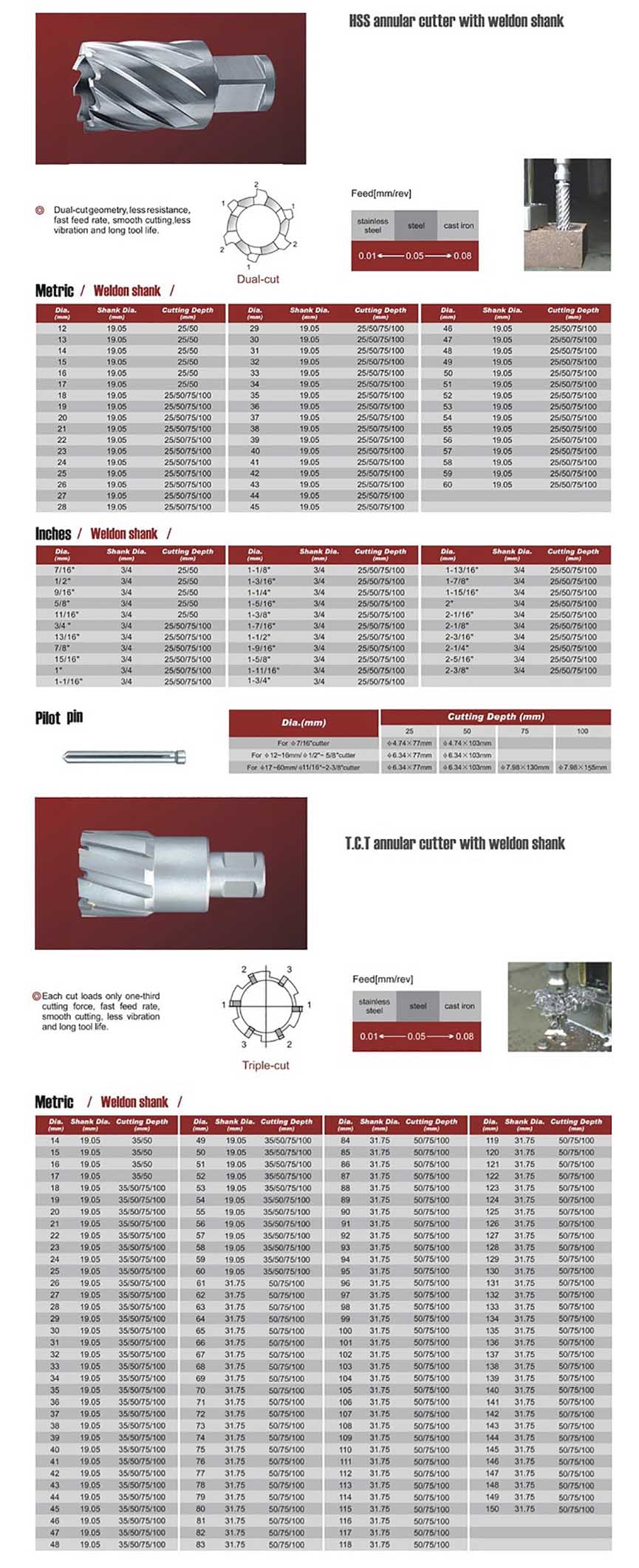

2. Multiple Cutting Teeth: TCT annular cutters typically have multiple cutting teeth arranged in a circular pattern around the periphery of the cutter. This design allows for faster and more efficient cutting, reducing cutting forces and improving chip removal.

3. Heat Resistance: Tungsten carbide tips have excellent heat resistance, allowing TCT annular cutters to withstand high temperatures generated during cutting. This property helps to prevent overheating and prolongs the tool's lifespan.

4. Precise and Clean Cuts: The sharp and durable tungsten carbide teeth of TCT annular cutters enable precise and clean hole drilling. This results in minimal burrs, leading to a high-quality finish and reducing the need for additional deburring operations.

5. Versatility: TCT annular cutters are available in various sizes and cutting depths, making them suitable for a wide range of hole drilling applications. They can be used in industries such as metalworking, fabrication, construction, automotive, and more.

6. Shank Design: TCT annular cutters often come with a standard Weldon shank, allowing for easy and secure tool clamping in magnetic drilling machines or other compatible drilling equipment.

FIELD OPERATION DIAGRAM