TCT Rail annular cutter with slug shank

Features

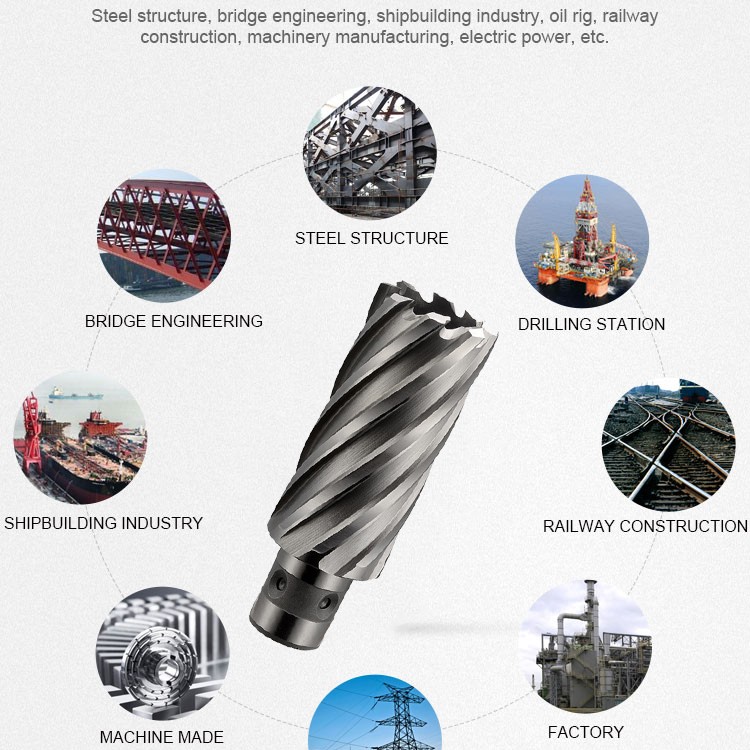

The TCT (tungsten carbide tip) orbital ring cutter with ferrule shank has a variety of functions that make it a specialized and efficient tool for cutting and drilling in railway applications:

1. Tungsten carbide (TCT) cutting edge: TCT material has excellent hardness and wear resistance, allowing the ring cutter to withstand the requirements of cutting tough railway materials such as rails.

2. Ferrule handle design: The ferrule handle is specially designed for rail cutting applications, providing a safe and stable connection with the drilling machine, minimizing vibration and improving accuracy during cutting operations.

3. Track-specific design: Ring cutters are designed to meet the unique requirements of railroad maintenance and construction, including the ability to efficiently and accurately cut hardened rails.

4. Efficient material removal: The block handle design facilitates efficient removal of cutting material (blocks) from the guide rail, reducing the risk of jamming and ensuring smooth cutting operations.

5. Reduce Chatter and Vibration: The ferrule shank design helps minimize chatter and vibration during cutting, helping to improve cutting quality and reduce tool and drill press wear.

6. Compatibility: Ring cutters with insert shanks are designed to be compatible with specific rail cutters, ensuring seamless integration and optimal performance in rail maintenance and construction applications.

7. Long service life: The TCT rail ring milling cutter with ferrule shank is carefully designed and durable to extend tool life and provide a cost-effective solution for rail cutting operations.

8. Precision Cutting: The specialized design and TCT cutting edges enable the ring cutter to make precise, clean cuts on rail materials, minimizing the need for additional finishing operations.

FIELD OPERATION DIAGRAM