TCT Saw Blade for Stainless Steel

Advantages

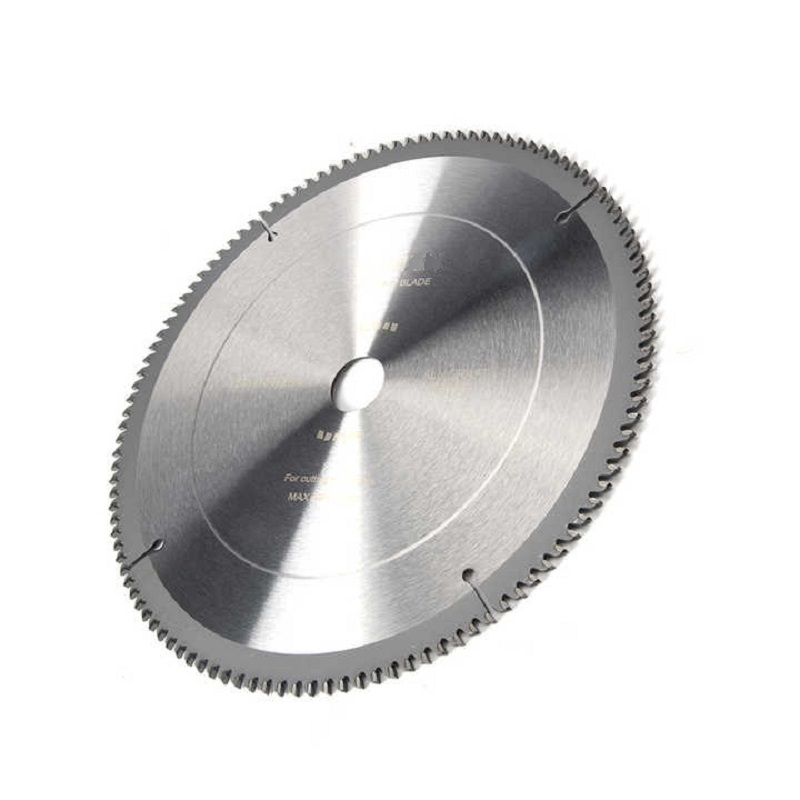

1. Material: Saw blades for cutting stainless steel are typically made of carbide or cermet (ceramic/metal) materials. These materials are much harder and more heat-resistant than standard steel blades, allowing for efficient and precise cutting through stainless steel.

2. Tooth Design: Saw blades for stainless steel have a unique tooth design that is optimized for metal cutting. The teeth are typically smaller and closer together compared to wood-cutting blades, enabling them to effectively penetrate the hard surface of stainless steel.

3. High Tooth Count: Metal cutting saw blades usually have a high tooth count, meaning there are more teeth per inch or centimeter. This helps to provide a finer and more precise cut through the stainless steel material.

4. Carbide or Cermet Tips: The tips of the teeth on these blades are usually made of tungsten carbide or a cermet material. These materials are extremely hard and can withstand the high heat generated during metal cutting, ensuring the sharpness and longevity of the blade.

5. Coolant Slots: Some metal cutting blades may feature coolant slots or laser-cut vents along the body of the blade. These slots help to dissipate heat and prevent the blade from overheating, which can result in dulling or warping of the blade.

6. Lubrication: Using appropriate metal cutting lubricants or coolants while cutting stainless steel with a TCT saw blade is essential. The lubricant helps reduce friction and heat buildup, ensuring smoother cuts and prolonging the life of the blade.

FACTORY

| Diameter | Kerf | Plate Thickness | Arbor Hole Size | Teeth Number | |

| Inch | mm | mm | mm | mm | |

| 6-1/4″ | 160 | 3 | 2 | 25.4 | 40 |

| 6-1/4″ | 160 | 3 | 2 | 30 | 40 |

| 7″ | 180 | 3 | 2.2 | 30 | 60 |

| 8″ | 200 | 3.2 | 2.2 | 30 | 48 |

| 8″ | 205 | 3 | 2.2 | 25.4 | 48 |

| 10″ | 255 | 3 | 2.2 | 25.4 | 60 |

| 10″ | 255 | 3 | 2.2 | 25.4 | 72 |

| 12″ | 300 | 3 | 2.2 | 30 | 66 |

| 12″ | 300 | 3 | 2.2 | 30 | 72 |

| 12″ | 305 | 3 | 2.2 | 30 | 72 |

| 12″ | 305 | 3 | 2.2 | 30 | 90 |

| 14″ | 355 | 3 | 2.2 | 25.4 | 100 |

| 14″ | 355 | 3 | 2.2 | 25.4 | 120 |

| 14″ | 355 | 3 | 2.2 | 30 | 100 |

| 14″ | 355 | 3 | 2.2 | 30 | 120 |

| 16″ | 400 | 3.2 | 2.2 | 25.4 | 100 |

| 16″ | 400 | 3.2 | 2.2 | 25.4 | 120 |

| 16″ | 405 | 3.2 | 2.2 | 30 | 100 |

| 16″ | 405 | 3.2 | 2.2 | 30 | 120 |

| 18″ | 450 | 3.2 | 2.4 | 30 | 100 |

| 18″ | 450 | 3.2 | 2.4 | 30 | 120 |

| 20″ | 500 | 3.8 | 2.8 | 25.4 | 100 |

| 20″ | 500 | 3.8 | 2.8 | 30 | 120 |