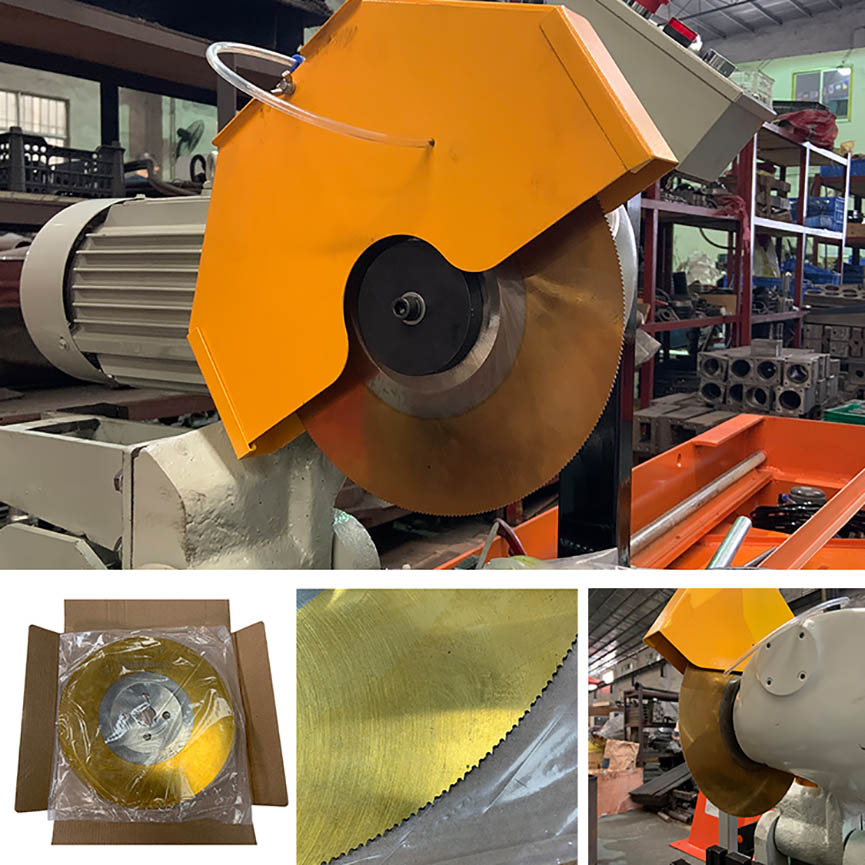

Titanium coating HSS circular Saw Blade

Features

1. Titanium coating enhances wear resistance, allowing the saw blade to maintain sharpness and cutting performance for a long time.

2. Titanium coating helps extend the tool life of the saw blade, reduces the frequency of saw blade replacement, and helps save costs.

3. Titanium coating reduces friction during cutting, resulting in smoother cuts, reduced heat generation and improved chip evacuation.

4. Titanium coating enhances the heat resistance of the saw blade, allowing it to withstand the high temperatures generated during cutting operations.

5. Titanium coating provides corrosion resistance, making the saw blade suitable for use in various cutting environments and a variety of materials.

6. Titanium coating helps improve the surface finish of the material being cut, reducing the need for additional finishing operations.

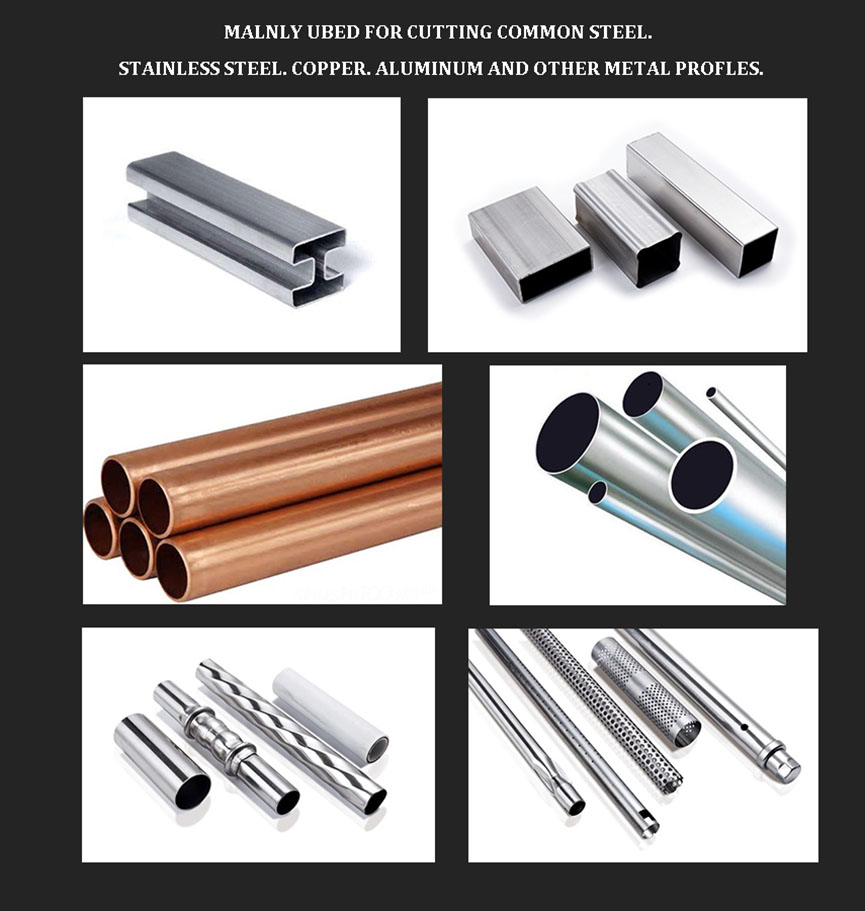

7. Titanium-coated high-speed steel circular saw blades are suitable for cutting a variety of materials, including wood, plastics, non-ferrous metals and some ferrous metals, making them adaptable to different cutting applications.

8. Titanium coating helps reduce cutting forces, making cutting operations smoother and reducing wear on saw blades and cutting equipment.

Overall, the titanium coating on HSS circular saw blades enhances their performance, durability, and versatility, making them suitable for a variety of cutting tasks in woodworking, metalworking, and other industrial applications.

hss cobalt saw blade