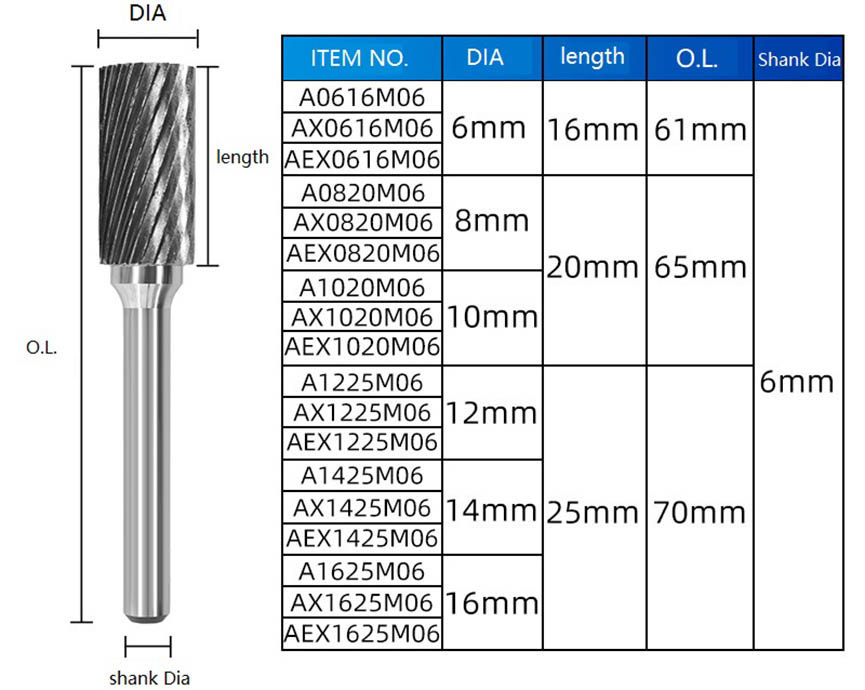

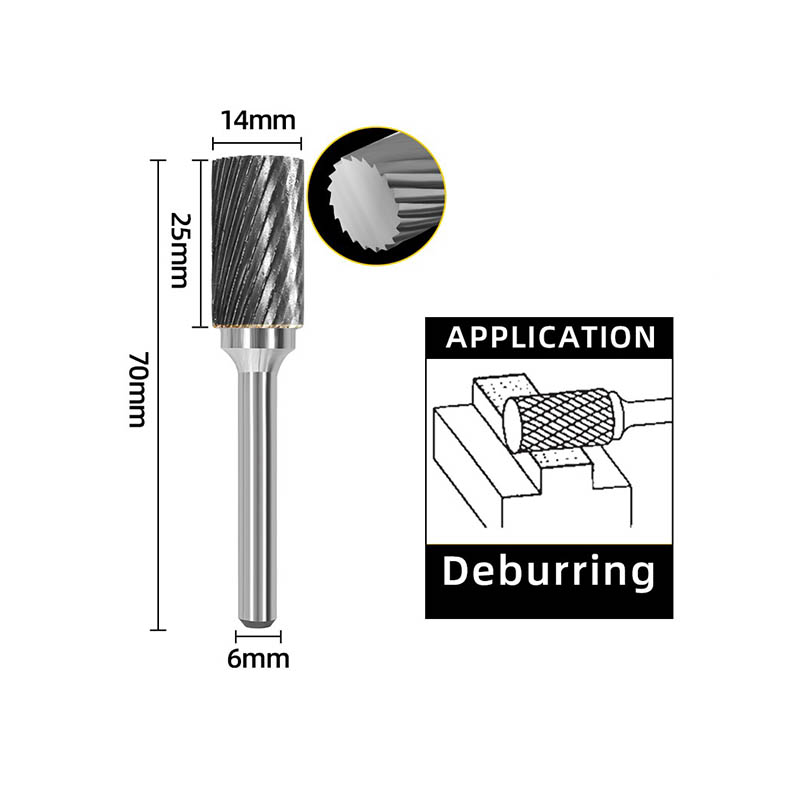

Tungsten Carbide A type Cylinder Rotary Burrs

Features

Widely used in all kinds industrial, like machine, cars, vessel, Craft sculpture etc.

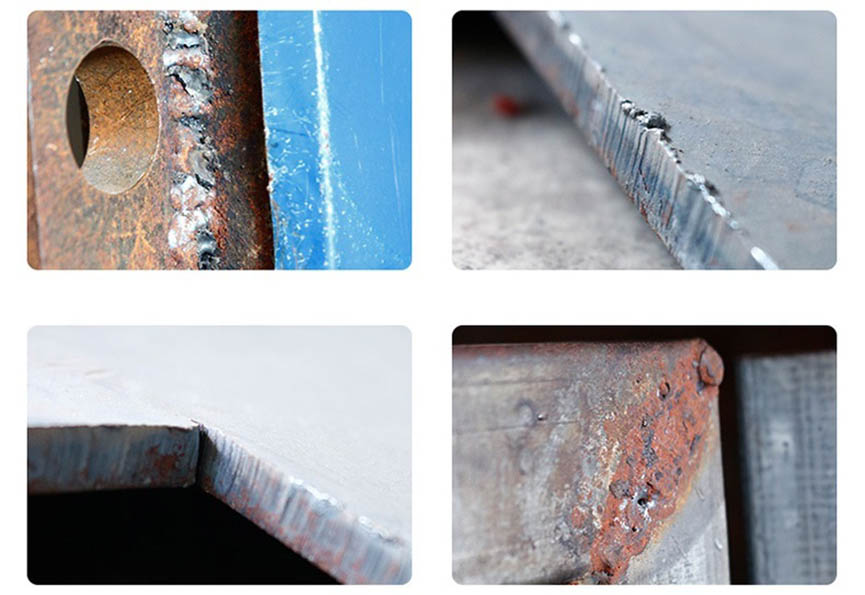

1. Fine finishing on all kinds of metal mould cavity.

2. Working on all kinds of metal and nonmetal's Craft sculpture.

3. Cleaning those trimming, burrs and weld line on casting, forge and weldment part.

4. Chamfering and rounding and processing the bore surface on machine part, cleaning the pipeline.

5. Sleeking on the impeller runner part.

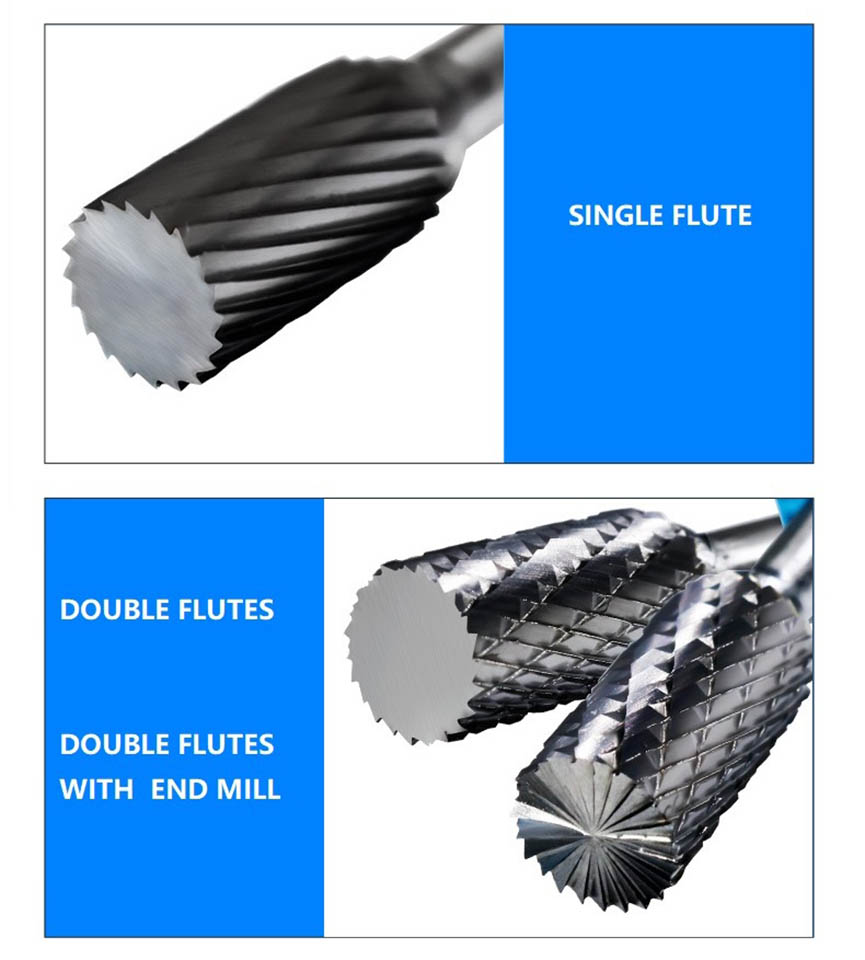

PRODUCT DETAILS

Advantages

1. Tungsten carbide is an extremely hard and durable material, making A-type rotary burrs highly resistant to wear and abrasion. They can withstand high-speed cutting and demanding applications without losing their sharpness or effectiveness.

2. A-type rotary burrs can be used on various materials, including metals, plastics, composites, and wood. They are suitable for shaping, deburring, grinding, and removing material with precision and ease.

3. Tungsten carbide has excellent heat resistance properties, enabling A-type rotary burrs to withstand high temperatures during cutting applications. This resistance prevents overheating and prolongs the burr's lifespan.

4. The sharp cutting edges of tungsten carbide A-type rotary burrs enable fast and efficient material removal. They can remove material quickly, saving time and effort.

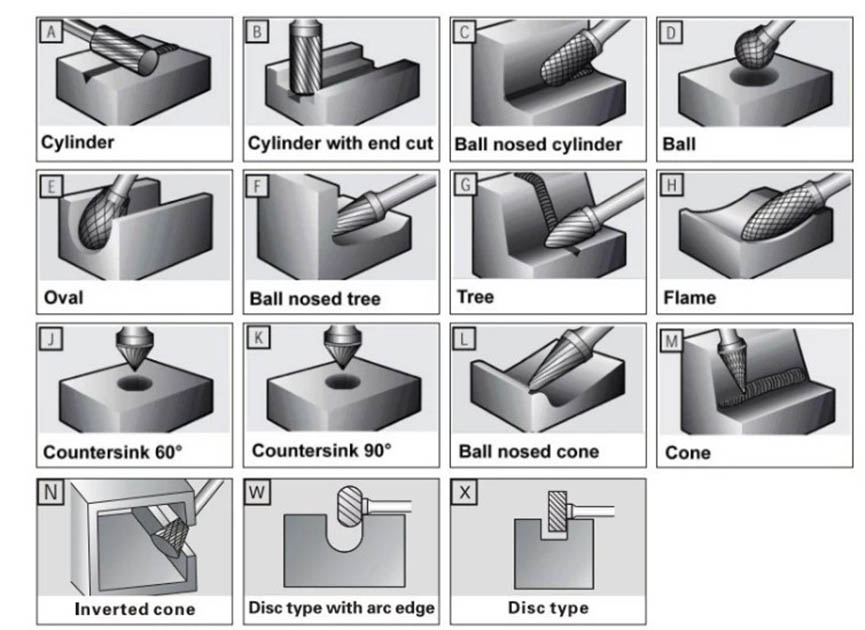

5. A-type rotary burrs have a cylindrical shape with a rounded nose, making them suitable for intricate and detailed work. They offer precise and accurate cutting, allowing for smooth finishes and precise contours.

6. Tungsten carbide A-type rotary burrs have a long service life due to their hardness and resistance to wear. They can withstand heavy use and demanding applications without the need for frequent replacement.

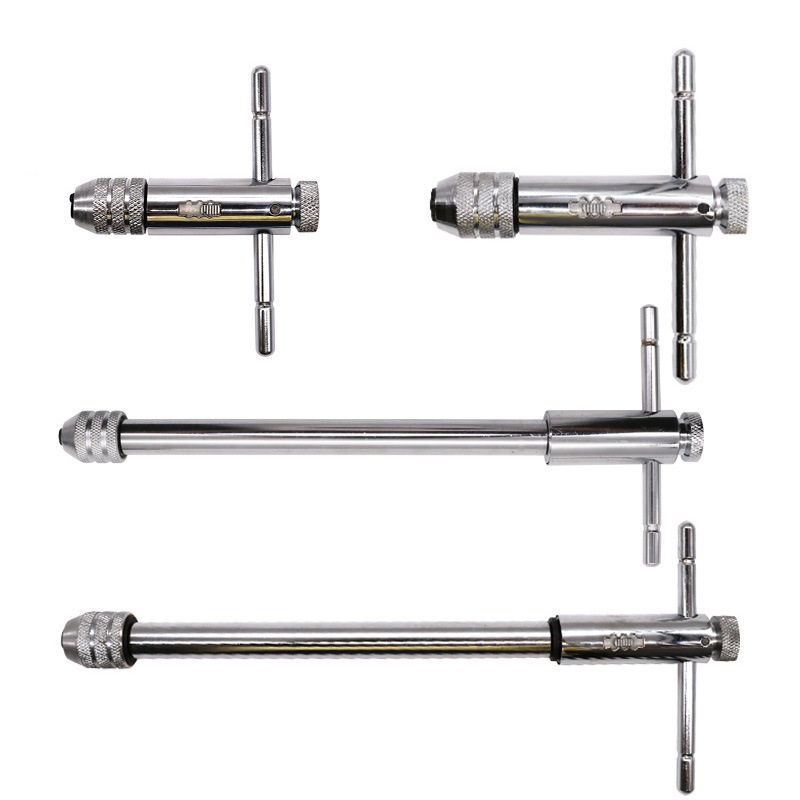

7. These burrs are designed to be used with high-speed rotary tools, such as die grinders or electric drills. They are compatible with various tool manufacturers' devices, making them accessible and widely used.