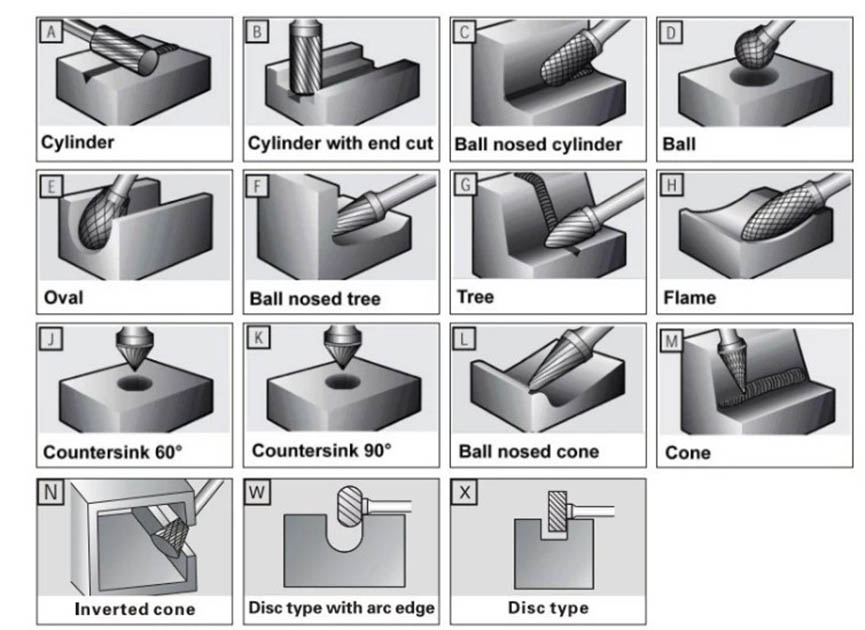

Tungsten Carbide B type Rotary Burrs with end cut

Type B carbide burr is suitable for machining surface profile and the interchange of two right angle surface of workpiece.

Advantages

1. Efficient Material Removal: The end cut design of B type rotary burrs allows for efficient and rapid material removal. The cutting edges on the end of the burr are ideal for roughing out or removing larger amounts of material quickly.

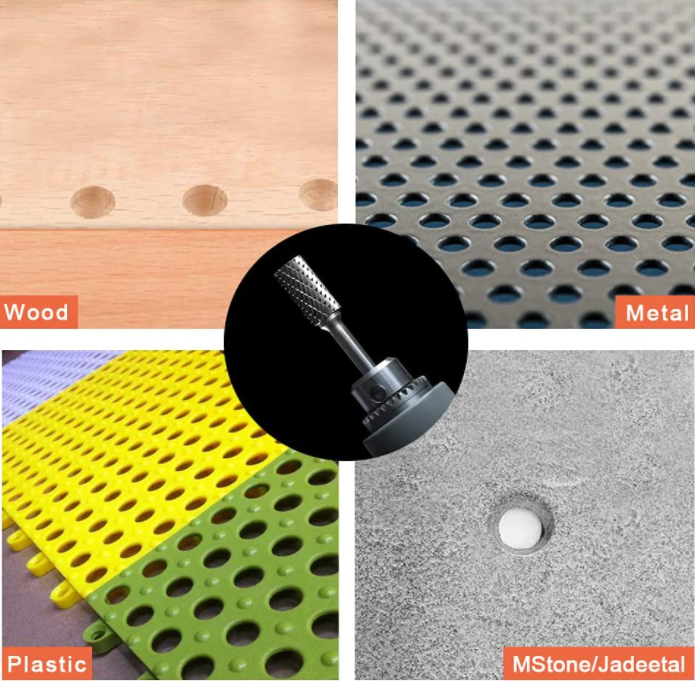

2. Versatility: B type rotary burrs can be used on a variety of materials, including metals, plastics, composites, and wood. They are suitable for tasks such as shaping, deburring, and grinding, making them versatile tools for different applications.

3. The end cut design of B type burrs provides an aggressive cutting action, making them ideal for heavy-duty applications. They can quickly and effectively remove tough materials or work on harder surfaces.

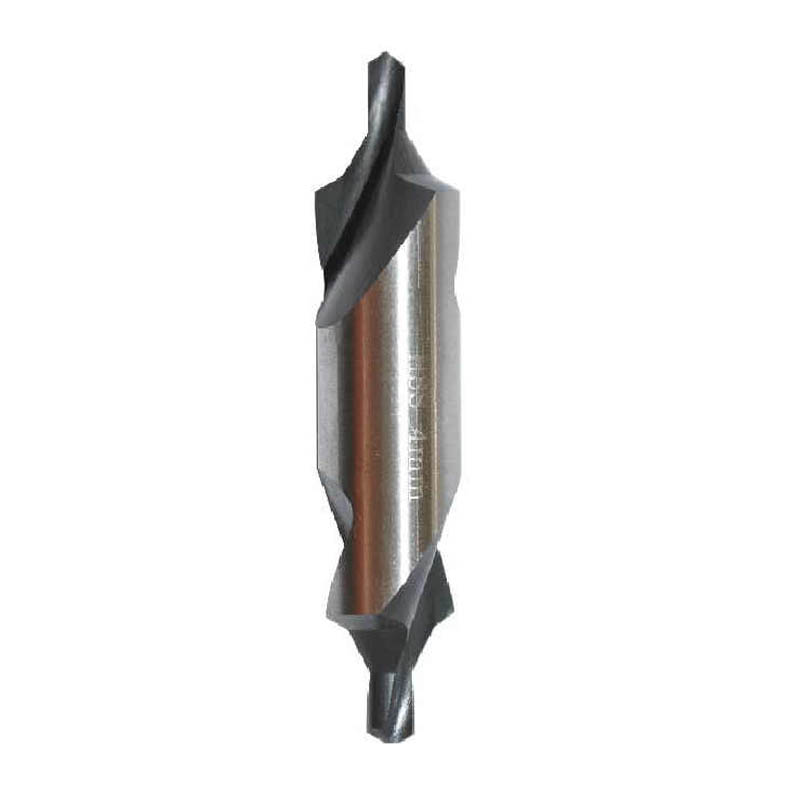

4. Tungsten carbide is known for its exceptional hardness and durability. B type rotary burrs are highly resistant to wear and abrasion, allowing them to maintain their sharpness and cutting effectiveness over a longer period. This ensures extended tool life and reduces the need for frequent replacements.

5. Tungsten carbide B type rotary burrs can withstand high temperatures generated during cutting operations. This heat resistance prevents the burrs from overheating, leading to improved performance and longevity.

6. Precision and Control: The end cut design of these burrs provides greater control and precision, especially when working on specific areas or creating fine details. It enables users to achieve precise contours, smooth finishes, or reach challenging areas that may be difficult to access with other burr designs.

7. Compatibility: B type rotary burrs are designed to be used with high-speed rotary tools such as die grinders or electric drills. They are compatible with various tool manufacturers' devices, making them easily accessible and widely used.

8. Tungsten carbide B type rotary burrs are relatively easy to maintain. They can be cleaned using a wire brush or air blower and are less prone to clogging or buildup during cutting applications.