Tungsten carbide Reamer with coating

Features

Coated tungsten carbide reamers have several properties that make them very effective in machining applications. Some key features include:

1. Hardness: Tungsten carbide is an extremely hard material, and reamers made of it have strong wear resistance. The coating further enhances the reamer's hardness and wear resistance.

2. Heat resistance: Coated tungsten carbide reamers can withstand the high temperatures generated during machining, making them suitable for use in high-speed machining operations.

3. Coating options: Coatings on tungsten carbide reamers vary, with commonly used coatings including titanium nitride (TiN), titanium carbonitride (TiCN), and aluminum titanium nitride (AlTiN). These coatings provide additional protection against wear and increase reamer performance and tool life.

4. Lubricity: The coating on tungsten carbide reamers can provide enhanced lubricity, reduce friction during cutting and improve chip evacuation.

5. Accuracy: Coated tungsten carbide reamers are capable of machining holes with high precision and precision, making them suitable for applications with tight tolerances.

6. Versatility: These reamers can be used on a variety of materials, including steel, stainless steel, cast iron, non-ferrous metals and composites, making them suitable for a variety of machining applications.

7. Extend tool life: The combination of tungsten carbide and coating allows the reamer to have a longer tool life than traditional high-speed steel reamers, reducing the frequency of tool changes and improving productivity.

Overall, coated tungsten carbide reamers offer a combination of hardness, heat resistance, and precision, making them a popular choice for demanding machining operations.

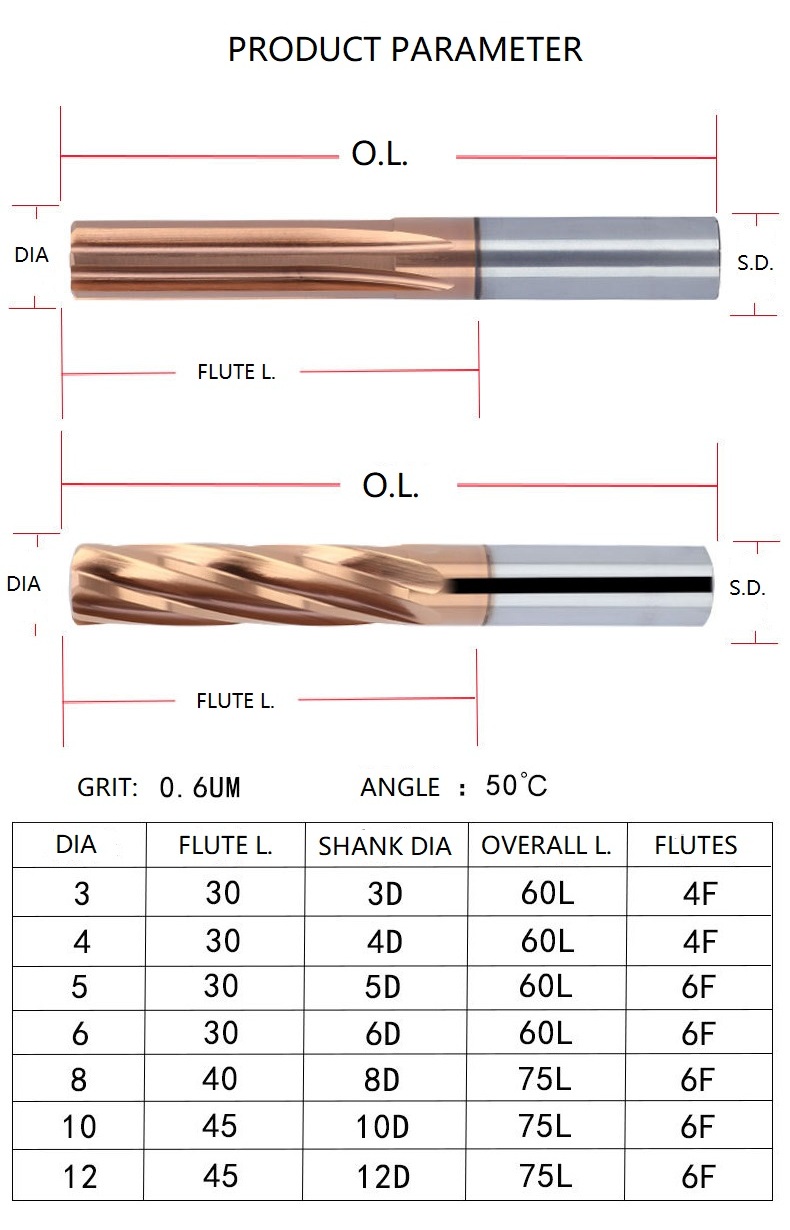

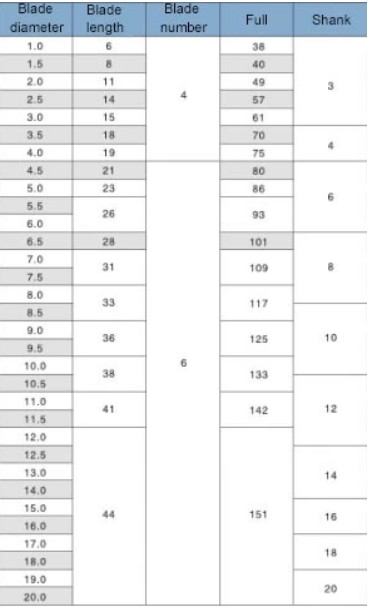

PRODUCT SHOW