Tungsten Carbide roughing End Mill

Features

Carbide roughing end mills have several notable features:

1. These end mills are designed to efficiently remove material during roughing, making them suitable for high-speed machining and heavy material removal.

2. Made of high-quality tungsten carbide, these end mills offer superior hardness and toughness to withstand the rigors of roughing applications.

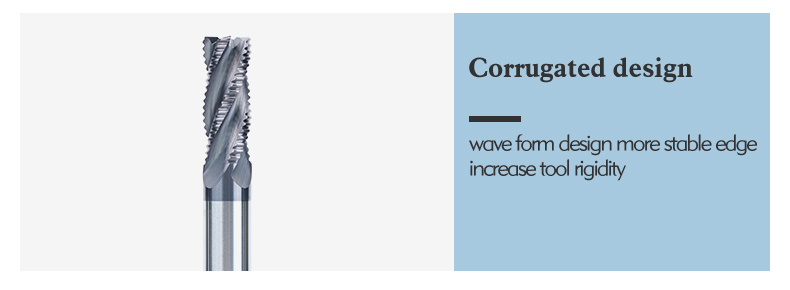

3. Roughing end mills feature a coarse tooth design that facilitates powerful cutting and chip evacuation, resulting in faster material removal rates.

4. Suitable for rough machining of a variety of materials, including steel, stainless steel, cast iron and other ferrous and non-ferrous metal materials.

5. End mills are designed to withstand the high temperatures generated during roughing, minimizing thermal deformation and ensuring extended tool life.

6. Some roughing end mills may feature special coatings such as TiCN (titanium carbonitride) or AlTiN (aluminum titanium nitride) to enhance wear resistance and extend the tool's use under harsh machining conditions. life.

7. End mills are engineered to provide stability and rigidity during aggressive cutting, reducing vibration and ensuring consistent performance.

8. Optimize the chip removal groove design and chip breaker geometry, which is conducive to efficient chip removal, prevents chip re-cutting, and improves processing efficiency.

PRODUCT SHOW