Tungsten Carbide Tapered End Mill

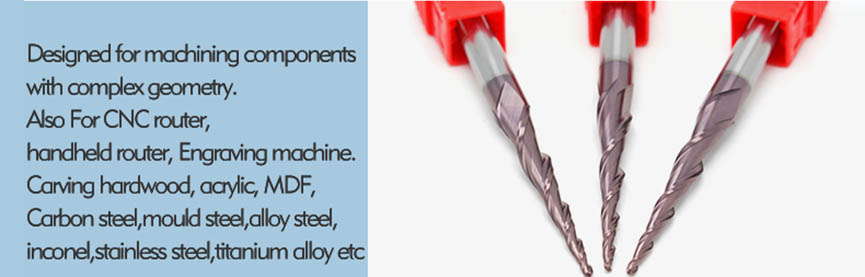

Features

1. Versatile machining capabilities: Tapered end mills can be used for a variety of machining operations, including contouring, slotting, and drilling. The taper design allows for efficient material removal and precise cutting in multiple directions.

2. Improved access and reach: The tapered shape of the end mill provides better access to difficult-to-reach areas and allows for deep milling operations. This is particularly advantageous when working with complex parts or inside cavities.

3. Enhanced chip evacuation: The flute design of tapered end mills helps to evacuate chips efficiently. With their larger flute volume and wider spacing, they are effective at removing chips from the cutting area, reducing the risk of chip recutting and improving overall tool performance.

4. Increased stability and rigidity: Tungsten carbide tapered end mills are designed to provide increased stability and rigidity during cutting. The conical shape helps to distribute cutting forces more evenly, reducing vibrations and minimizing deflection, resulting in improved accuracy and surface finish.

5. Multiple taper angles available: Tapered end mills come in various taper angles, such as 3°, 5°, 7°, and more. The choice of taper angle depends on the specific application requirements, such as the desired cutting diameter and the material being machined.

6. Coating options: Tungsten carbide tapered end mills can be coated with various coatings, such as TiAlN, TiCN, or AlTiN, to further enhance their performance. Coatings provide increased tool life, reduced friction, and improved heat resistance, depending on the specific coating applied.

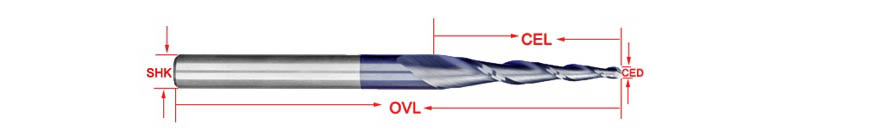

Detail display

FACTORY

| Two flutes spiral tapered ball nose end mills | |||||

| Applicable: Aluminum, plastic, plastic part, copper parts, aluminium alloy, stainless steel mould, wood | |||||

| NO | SHK | 1/2 CED(mm) | CEL | OVL | |

| 2fbn30.2515 | 3.175 | 0.25 | 15 | 38.5 | |

| 2fbn30.515 | 3.175 | 0.5 | 15 | 38.5 | |

| 2fbn30.7515 | 3.175 | 0.75 | 15 | 38.5 | |

| 2fbn31.015 | 3.175 | 1 | 15 | 38.5 | |

| 2fbn40.2515 | 4 | 0.25 | 15 | 50 | |

| 2fbn40.515 | 4 | 0.5 | 15 | 50 | |

| 2fbn40.7515 | 4 | 0.75 | 15 | 50 | |

| 2fbn41.015 | 4 | 1 | 15 | 50 | |

| 2fbn40.2520.5 | 4 | 0.25 | 20.5 | 50 | |

| 2fbn40520.5 | 4 | 0.5 | 20.5 | 50 | |

| 2fbn40.7520.5 | 4 | 0.75 | 20.5 | 50 | |

| 2fbn41.020.5 | 4 | 1 | 20.5 | 50 | |

| 2fbn60.2520.5 | 6 | 0.25 | 20.5 | 50 | |

| 2fbn60.520.5 | 6 | 0.5 | 20.5 | 50 | |

| 2fbn60.7520.5 | 6 | 0.75 | 20.5 | 50 | |

| 2fbn61.020.5 | 6 | 1 | 20.5 | 50 | |

| 2fbn602530.5 | 6 | 0.25 | 30.5 | 75 | |

| 2fbn60.530.5 | 6 | 0.5 | 30.5 | 75 | |

| 2fbn60.7530.5 | 6 | 0.75 | 30.5 | 75 | |

| 2fbn61.030.5 | 6 | 1 | 30.5 | 75 | |

| 2fbn61.530.5 | 6 | 1.5 | 30.5 | 75 | |

| 2fbn62.030.5 | 6 | 2 | 30.5 | 75 | |

| 2fbn80.547 | 8 | 0.5 | 47 | 85 | |

| 2fbn81.047 | 8 | 1 | 47 | 85 | |

| 2fbn81.547 | 8 | 1.5 | 47 | 85 | |

| 2fbn82047 | 8 | 2 | 47 | 85 | |

| 2fbn80.560 | 8 | 0.5 | 60 | 100 | |

| 2fbn81.060 | 8 | 1 | 60 | 100 | |

| 2fbn81.560 | 8 | 1.5 | 60 | 100 | |

| 2fbn82.060 | 8 | 2 | 60 | 100 | |

| 2fbn10270 | 10 | 2 | 70 | 110 | |

| 2fbn12270 | 12 | 2 | 70 | 120 | |