Tungsten Carbide thread End Mills

Features

Tungsten carbide thread end mills are cutting tools designed for machining threads on a variety of materials. Some of the key features of these end mills include:

1. Tungsten carbide is an extremely hard and durable material, making it ideal for cutting tough materials like steel, stainless steel, and other alloys.

2. Carbide thread end mills have excellent wear resistance, allowing them to maintain their cutting edges over long periods of use.

3. Tungsten carbide can withstand high temperatures, making it suitable for high-speed machining operations without losing its cutting performance.

4. These end mills are designed to create precise threads, ensuring high-quality results in threaded components.

5. Carbide thread end mills can be used for a variety of thread types, including internal and external threads, and various thread pitches.

6. Due to its hardness and wear resistance, carbide thread end mills have a longer service life than other materials, reducing the frequency of tool replacement.

7. Carbide end mills feature high cutting speeds and feed rates, allowing for efficient machining operations and increased productivity.

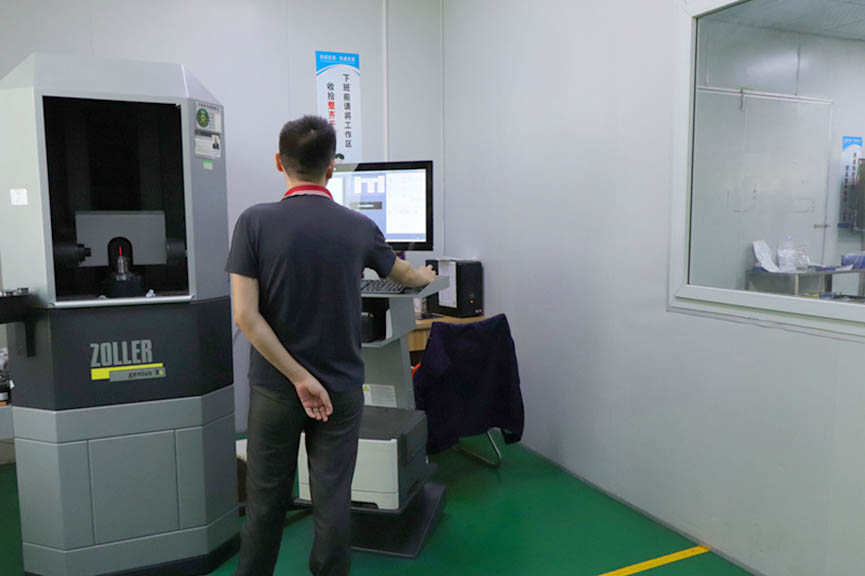

PRODUCT SHOW