Tungsten Carbide Twist Drill Bits With Nano Coating

Features

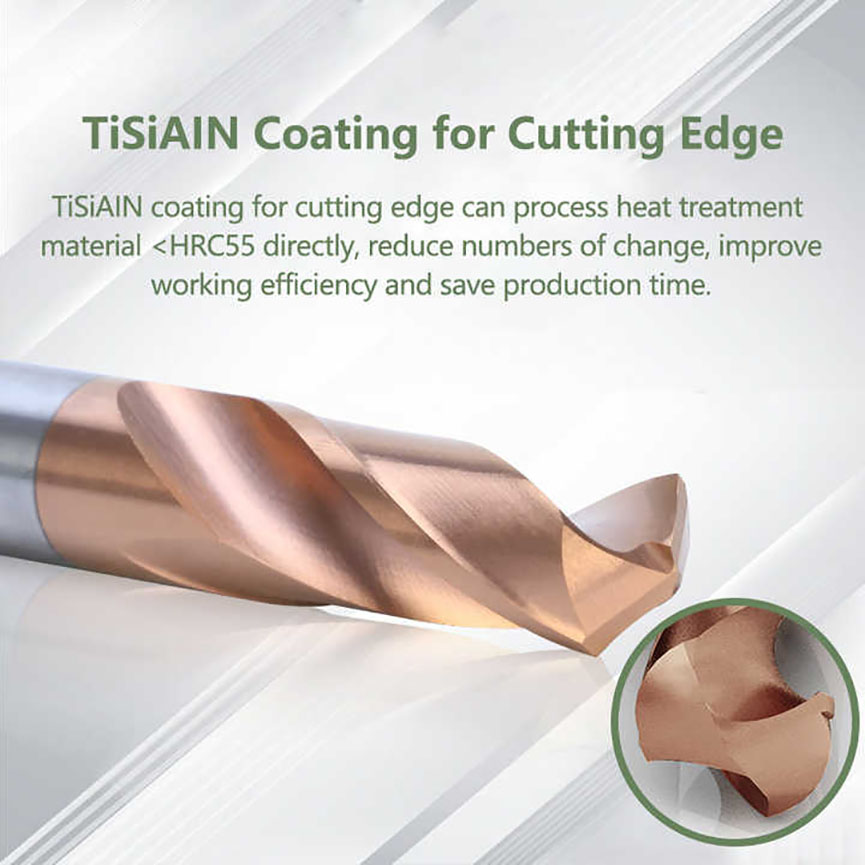

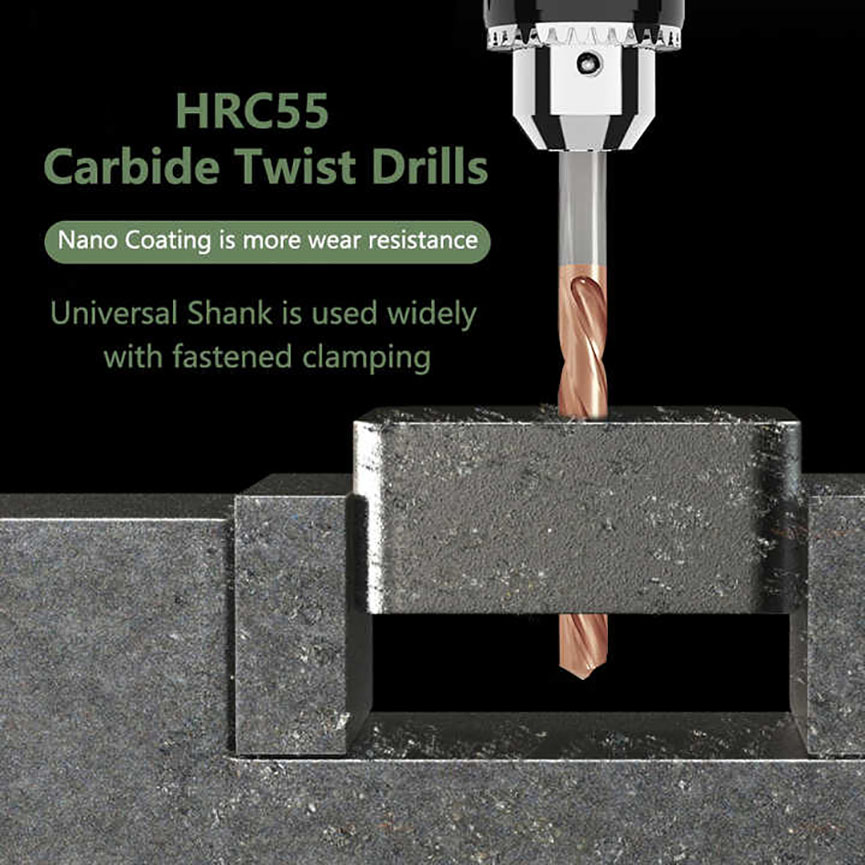

1. Enhanced Hardness and Wear Resistance: The nano coating applied to the tungsten carbide drill bits further enhances their hardness and wear resistance. This ensures even longer tool life and increased durability, allowing them to withstand even more demanding drilling applications.

2. Improved Lubricity: The nano coating can provide higher lubricity to the drill bit surface, reducing friction during drilling. This not only helps to minimize heat generation but also aids in smoother drilling operations and prevents the bit from getting stuck or binding in the material being drilled.

3. Increased Corrosion Resistance: The nano coating acts as a barrier against corrosion, protecting the tungsten carbide material from degradation caused by exposure to moisture, chemicals, or harsh environments. This extends the lifespan of the drill bit and ensures consistent performance over time.

4. Enhanced Chip Evacuation: The nano coating can improve the chip evacuation process by reducing the adhesion of chips to the flutes of the drill bit. This helps to prevent chip clogging, ensuring uninterrupted drilling and preventing damage to the workpiece.

5. Reduced Heat Build-up: The nano coating can also help dissipate heat more effectively, reducing the heat build-up during drilling. This is beneficial for high-speed drilling applications or when drilling heat-sensitive materials, as it helps to prevent overheating and subsequent damage to the drill bit or the workpiece.

6. Smoother Surface Finish: The nano coating can contribute to achieving a smoother surface finish on the drilled hole. This is particularly important for applications that require precision and aesthetics, as it helps to minimize surface imperfections and burrs.

7. Improved Cutting Performance: The nano coating can enhance the cutting performance of the drill bit by reducing friction and increasing the sharpness of the cutting edges. This leads to improved drilling efficiency, reduced energy consumption, and faster drilling speeds.

8. Enhanced Lubrication Retention: The nano coating can also improve the retention of lubricants or cutting fluids on the drill bit surface, ensuring better lubrication during drilling operations. This helps to further reduce friction, heat, and wear, while also providing additional corrosion protection.