Tungsten steel circular Saw Blade with titanium coating for metal cutting

Features

Titanium-coated tungsten steel circular saw blades have several key properties that make them efficient in cutting a variety of materials. Some key features include:

1. Tungsten steel, also known as carbide, is extremely hard and durable, making it ideal for cutting tough materials such as wood, metal, and plastic. The titanium coating further enhances the blade's wear and corrosion resistance, extending its service life.

2. Titanium coating provides heat resistance, reducing the risk of overheating during long-term use. This feature helps maintain the sharpness of the blade and prevents it from being deformed or damaged due to high temperatures.

3. Tungsten steel circular saw blades are known for their precision cutting capabilities, allowing for clean, accurate cuts on a variety of materials. The sharpness and hardness of the blade combined with the titanium coating contribute to smooth and efficient cutting performance.

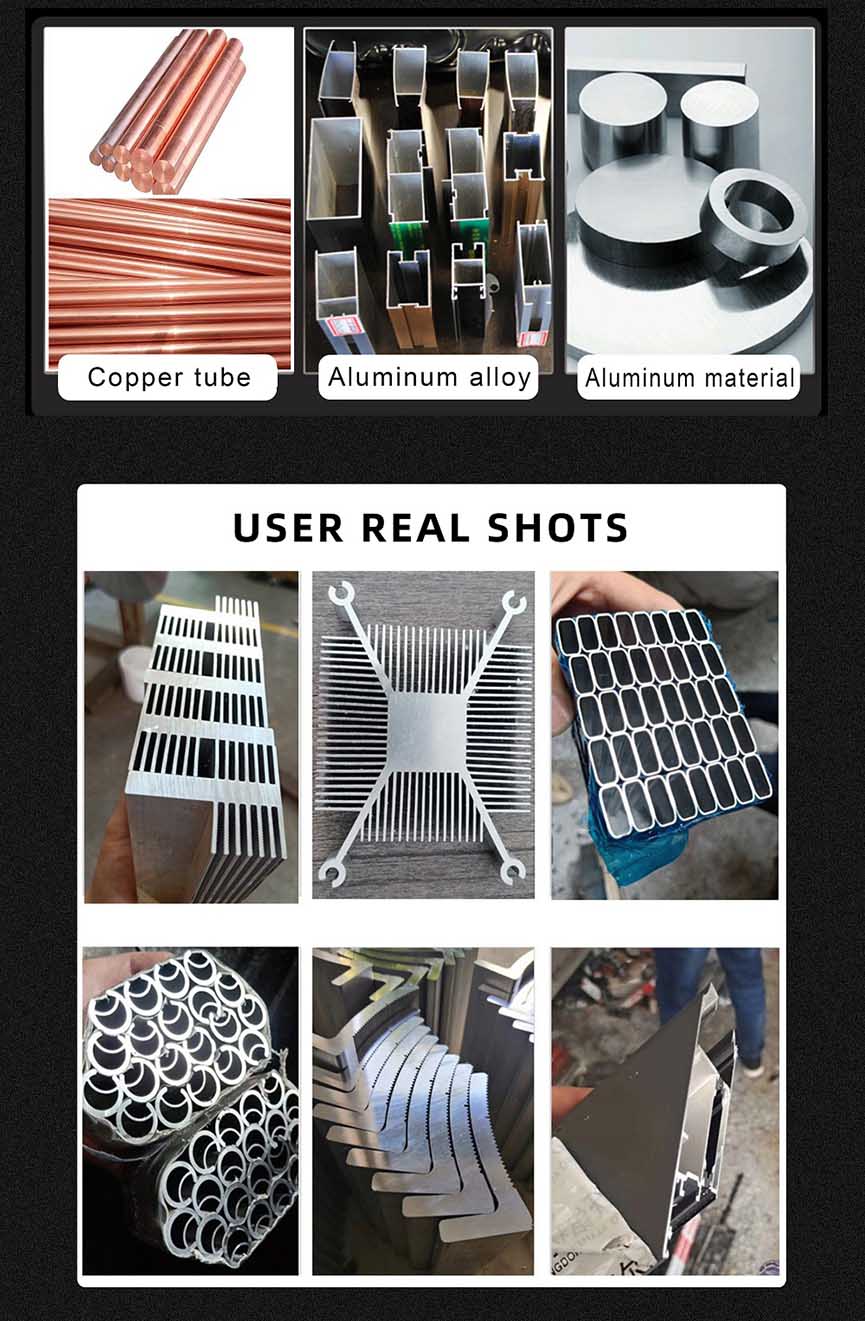

4. These saw blades are suitable for a variety of applications, including woodworking, metalworking, and general construction. The combination of tungsten steel and titanium coating allows the blade to handle different materials with ease.

5. Titanium coating reduces friction during cutting, which not only extends the life of the blade, but also helps make the cutting operation smoother and reduces heat build-up.

6. Titanium-coated tungsten steel circular saw blades are compatible with a variety of saws, including table saws, miter saws, and circular saws, making them a versatile choice for different cutting tasks.

PRODUCT SHOW