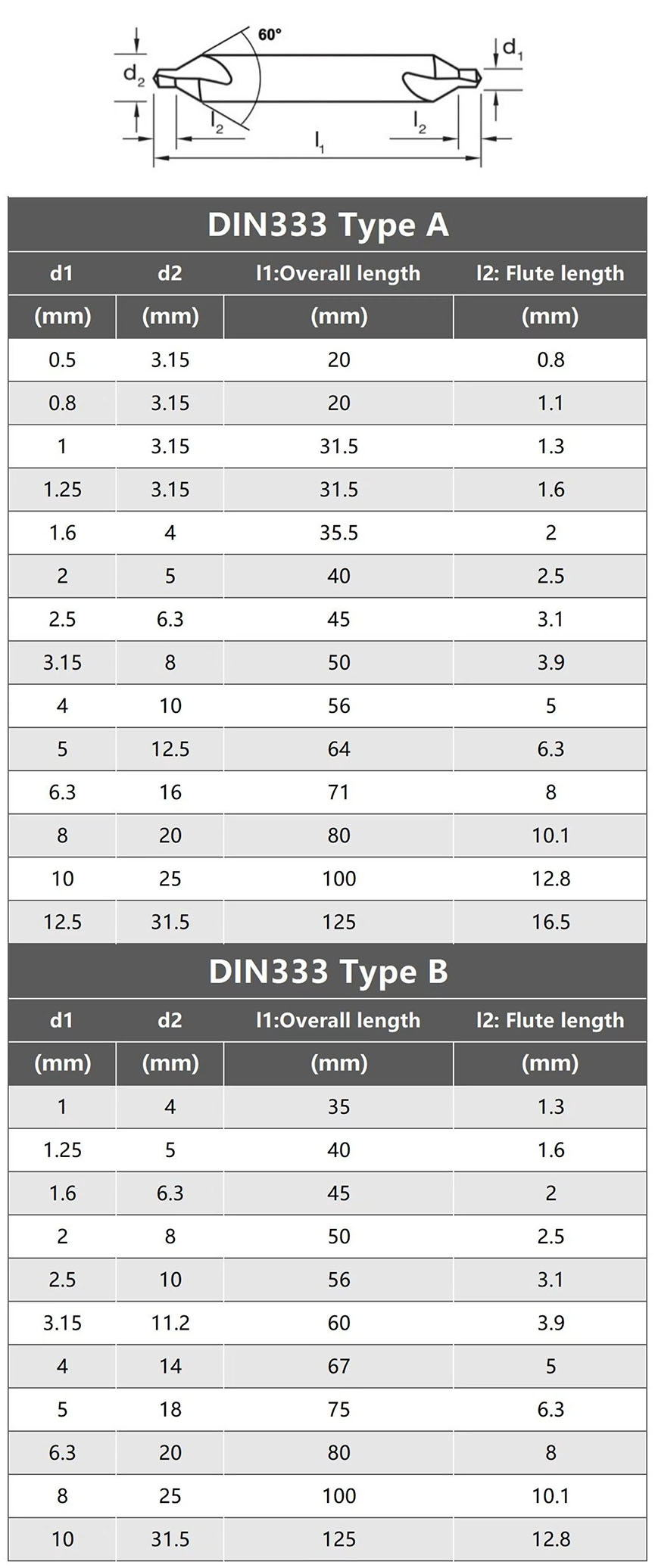

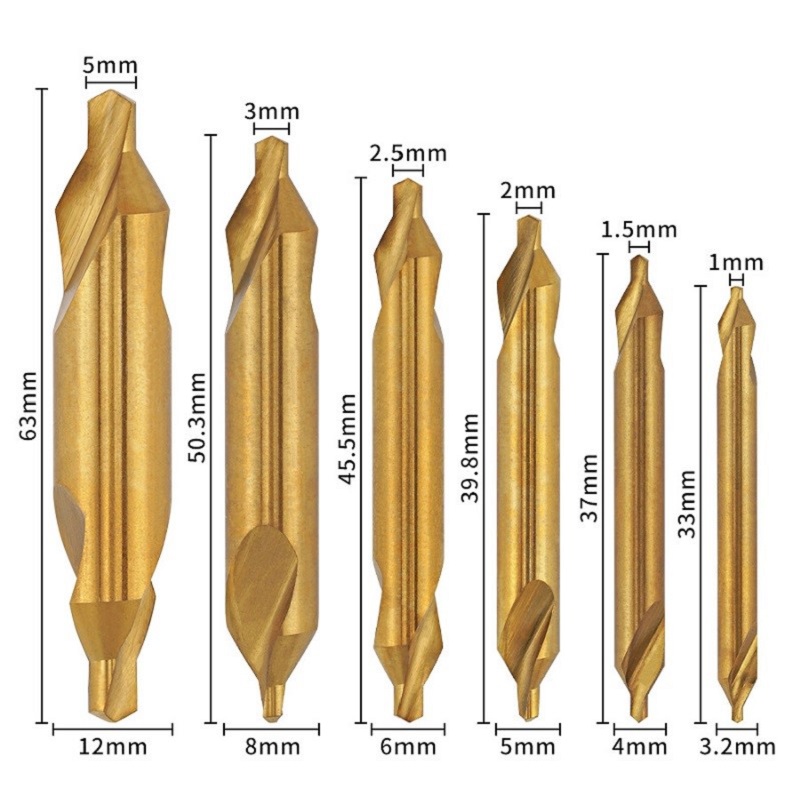

Type B Solid Carbide Center Drill Bits

FEATURES

Carbide Construction: Type B carbide drill bits are made from high-quality carbide material. Carbide is a composite material made from a combination of tungsten carbide particles and a metal binder, usually cobalt. This combination offers exceptional hardness and wear resistance, making them ideal for drilling into tough materials.

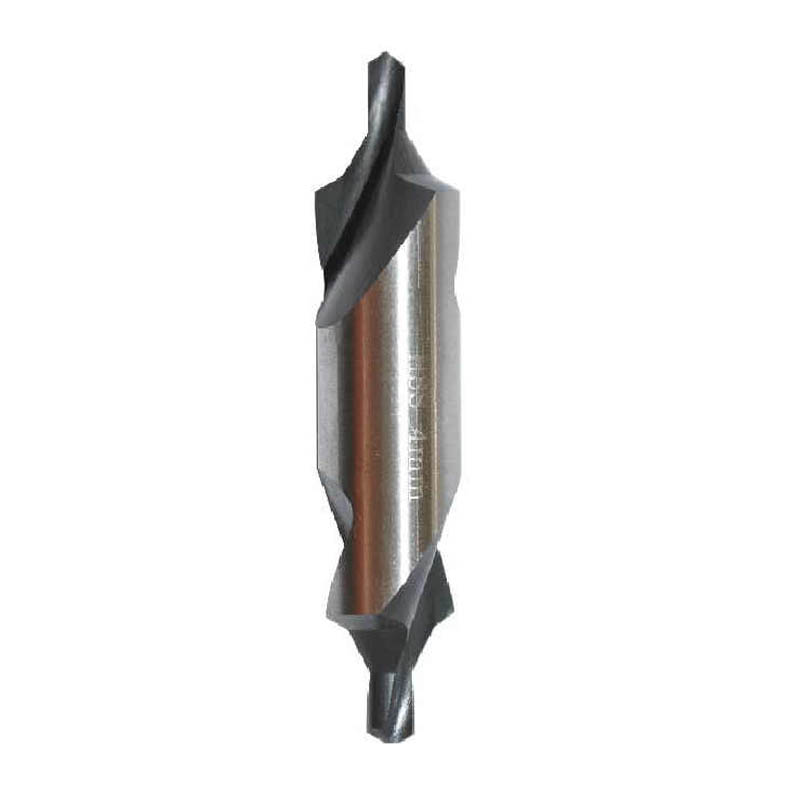

Split Point Design: Type B carbide drill bits often feature a split point design. This means that the drill bit has a self-centering characteristic, allowing for precise positioning and reduced walking or skating on the workpiece's surface.

Flute Design: Type B carbide drill bits usually have straight flutes. The straight flutes provide efficient chip evacuation during drilling, preventing chip clogging and reducing heat buildup.

High Heat Resistance: Carbide materials have excellent heat resistance. Type B carbide drill bits can withstand high drilling speeds and temperatures, which is essential when drilling into hard materials that generate a significant amount of heat during the drilling process.

Enhanced Surface Finish: Type B carbide drill bits are often designed with special surface coatings or treatments. These coatings, such as titanium nitride (TiN), provide additional hardness, lubricity, and reduced friction, resulting in improved surface finish and extended tool life.

Suitable for Precision Drilling: The combination of a sharp cutting edge, rigid construction, and high heat resistance makes Type B carbide drill bits suitable for precision drilling applications. They can create accurate holes with minimal deviation or damage to the workpiece.

Versatility: While Type B carbide drill bits are primarily designed for drilling harder materials, they can also be used for drilling softer materials. This versatility makes them a valuable tool in industries such as automotive, aerospace, manufacturing, and metalworking.

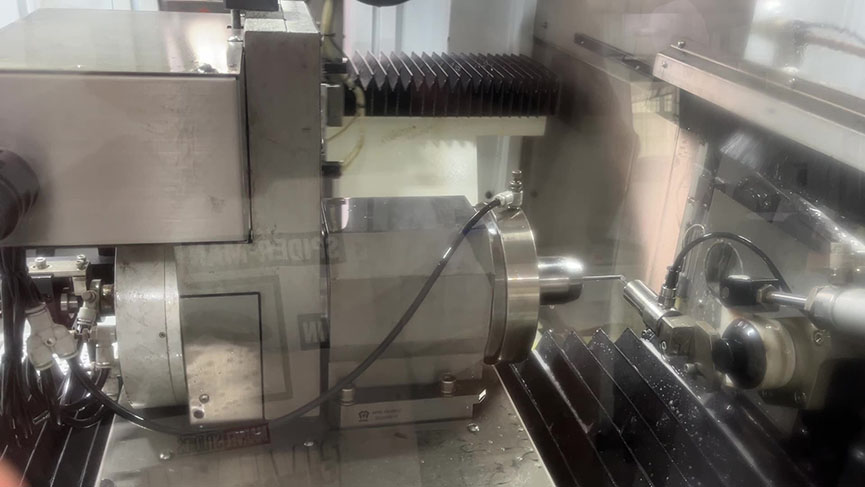

center drill bits machine