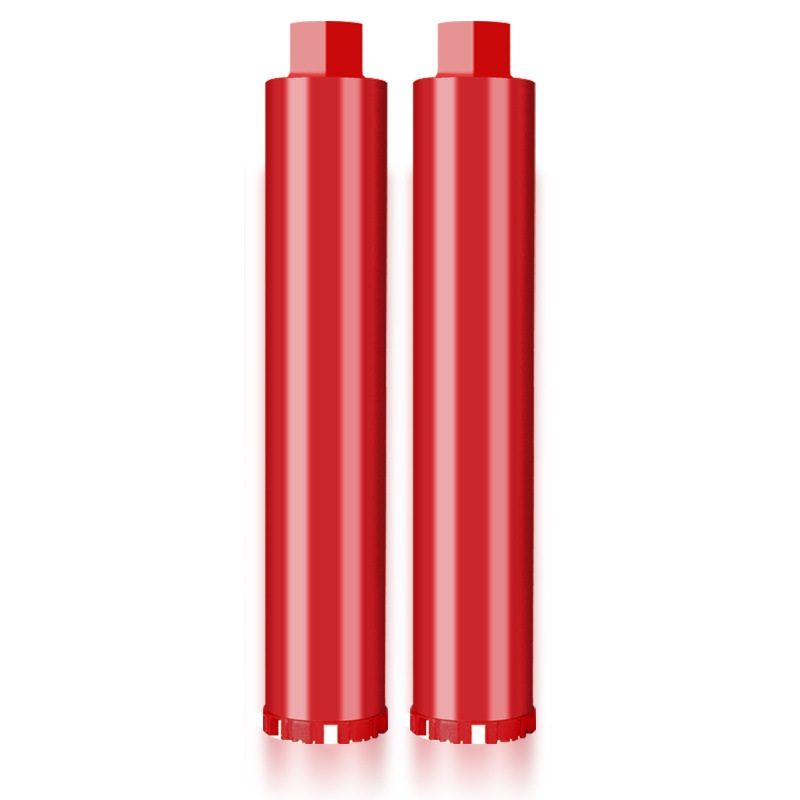

Vacuum Brazed Diamond Core Drill Bits for Concrete and Stone

Advantages

1. Vacuum brazing is a manufacturing process that fuses diamond particles directly to the drill bit's steel body using high temperatures and vacuum pressure. This results in a strong and durable bond between the diamond grit and the drill bit, ensuring excellent cutting performance and efficient material removal.

2. The vacuum brazing process produces a secure and long-lasting bond between the diamond and the drill bit. This significantly extends the lifespan of the drill bit compared to other types of core drill bits. With proper care and usage, vacuum brazed diamond core drill bits can provide consistent and reliable performance over an extended period.

3. The diamond particles attached to the surface of the drill bit provide fast and aggressive cutting action. This means that vacuum brazed diamond core drill bits can quickly and efficiently penetrate the toughest concrete and stone surfaces, reducing drilling time and increasing productivity.

4. These drill bits are suitable for a wide range of applications, including drilling holes in concrete, stone, marble, granite, ceramic tiles, and other hard materials. Their versatile design makes them compatible with various drilling equipment, such as core drilling machines, angle grinders, and hand drills.

5. Vacuum brazed diamond core drill bits are designed to minimize chipping and cracking during the drilling process. The diamond grit's sharpness and precision cut through the material cleanly, reducing the risk of damage to the surrounding area.

6. The vacuum brazing process enhances the drill bit's heat resistance, allowing it to withstand the high temperatures generated during drilling. This helps prevent overheating and reduces the risk of premature wear or damage to the drill bit.

7. The sharp and evenly distributed diamond particles on the drill bit's surface ensure smooth and clean holes. This is especially important when drilling in concrete or stone, as it helps maintain the integrity and aesthetics of the material.

8. While vacuum brazed diamond core drill bits may have a higher initial cost compared to other types of drill bits, their long-lasting performance and durability make them a cost-effective investment in the long run. Their extended lifespan reduces the need for frequent replacements, resulting in savings over time.

vacuum brazed diamondcore bit detail

| Size | Diameter | Overall L | Working L | Shank L |

| 6mm | 6mm | 64mm | 30mm | 30mm |

| 8mm | 8mm | 64mm | 30mm | 30mm |

| 10mm | 10mm | 64mm | 30mm | 30mm |

| 12mm | 12mm | 64mm | 30mm | 30mm |

| 14mm | 14mm | 64mm | 30mm | 30mm |

| 16mm | 16mm | 64mm | 30mm | 30mm |

| 18mm | 18mm | 64mm | 30mm | 30mm |

| 20mm | 20mm | 64mm | 30mm | 30mm |

| 22mm | 22mm | 64mm | 30mm | 30mm |

| 25mm | 25mm | 64mm | 30mm | 30mm |

| 28mm | 28mm | 64mm | 30mm | 30mm |

| 30mm | 30mm | 64mm | 30mm | 30mm |

| 32mm | 32mm | 64mm | 30mm | 30mm |

| 35mm | 35mm | 64mm | 30mm | 30mm |

| 40mm | 40mm | 64mm | 30mm | 30mm |

| 45mm | 45mm | 64mm | 30mm | 30mm |

| 50mm | 50mm | 64mm | 30mm | 30mm |

| 55mm | 55mm | 64mm | 30mm | 30mm |

| 60mm | 60mm | 64mm | 30mm | 30mm |