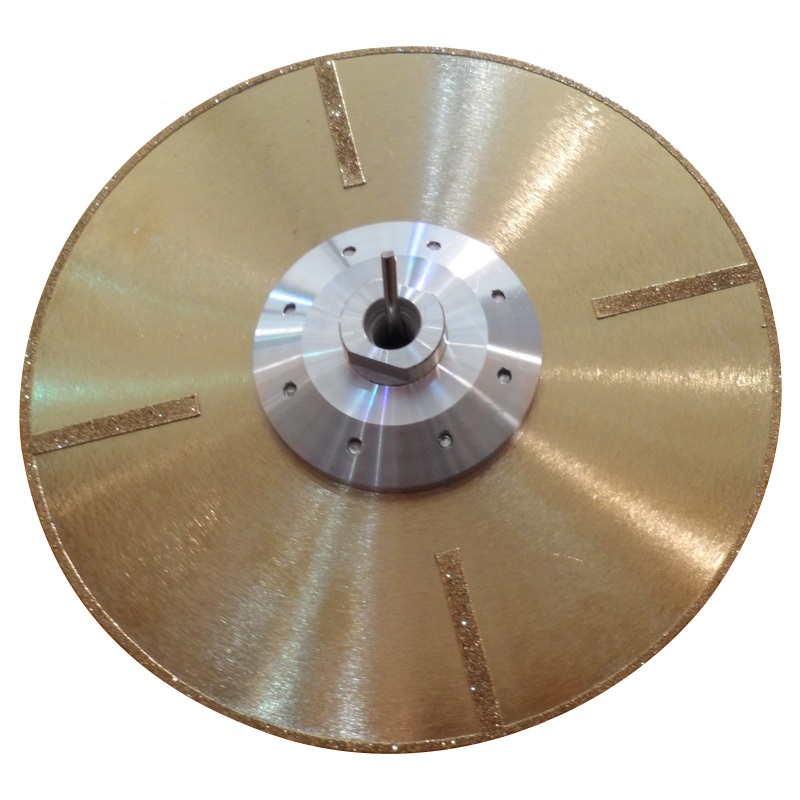

Vacuum Brazed Roma Type Diamond grinding Profile Wheels

Advantages

1. Precision profiling: Vacuum brazed Roma type diamond grinding profile wheels offer precise profiling capabilities. The vacuum brazing process ensures a strong bond between the diamond particles and the profile wheel, allowing for accurate shaping and grinding of various materials. This makes them ideal for creating intricate profiles and contours on surfaces.

2. Versatility in material compatibility: Vacuum brazed Roma type diamond grinding profile wheels are suitable for a wide range of materials, including stone, ceramics, glass, and composites. This versatility makes them a valuable tool for professionals working in various industries, such as stone fabrication, construction, and automotive.

3. Fast material removal: The vacuum brazed diamond technology used in these profile wheels enhances their cutting efficiency and speed. The diamond particles are firmly bonded to the profile wheel, enabling aggressive material removal and reducing the time required for grinding and profiling tasks. This leads to increased productivity and shorter project completion times.

4. Extended tool life: Vacuum brazed Roma type diamond grinding profile wheels have a longer lifespan compared to traditional profile wheels. The strong bond between the diamond particles and the profile wheel provides exceptional durability and resistance to wear, ensuring the profile wheel maintains its cutting effectiveness over a prolonged period. This reduces the need for frequent replacements, resulting in cost savings.

5. Smooth and clean finishes: The vacuum brazed diamond coating on the profile wheel's surface ensures a smooth and clean finish during the grinding and profiling process. The sharp and evenly distributed diamond particles deliver precise cuts, reducing the occurrence of chipping or splintering. This allows for high-quality results with minimal surface imperfections.

6. Easy to use: Vacuum brazed Roma type diamond grinding profile wheels are user-friendly and easy to use. They can be easily installed on compatible grinding machines or handheld tools, making them suitable for professionals and DIY enthusiasts alike. Their ease of use contributes to enhanced efficiency in grinding and profiling operations.

7. Reduced heat generation: The vacuum brazed diamond technology enhances heat dissipation during the grinding process. This reduces the risk of heat-induced damage to the material being worked on, such as thermal cracking or discoloration. It also contributes to a longer tool life by minimizing the impact of heat on the profile wheel.

8. Compatibility with dry and wet grinding: Vacuum brazed Roma type diamond grinding profile wheels can be used for both dry and wet grinding applications. This versatility allows users to select the most suitable method based on their specific requirements and preferences. Wet grinding provides effective cooling and dust suppression, while dry grinding offers convenience and flexibility.

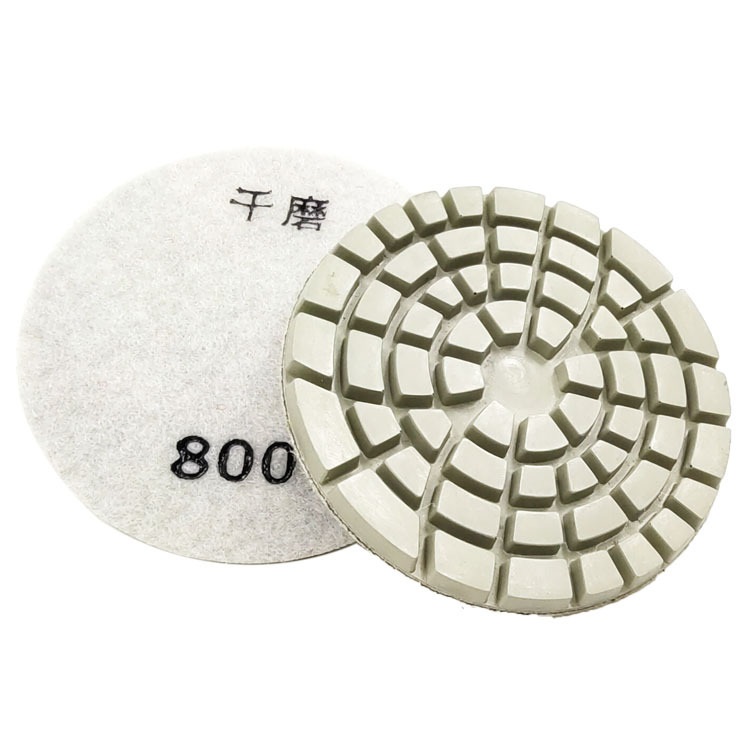

PRODUCT DISPLAY

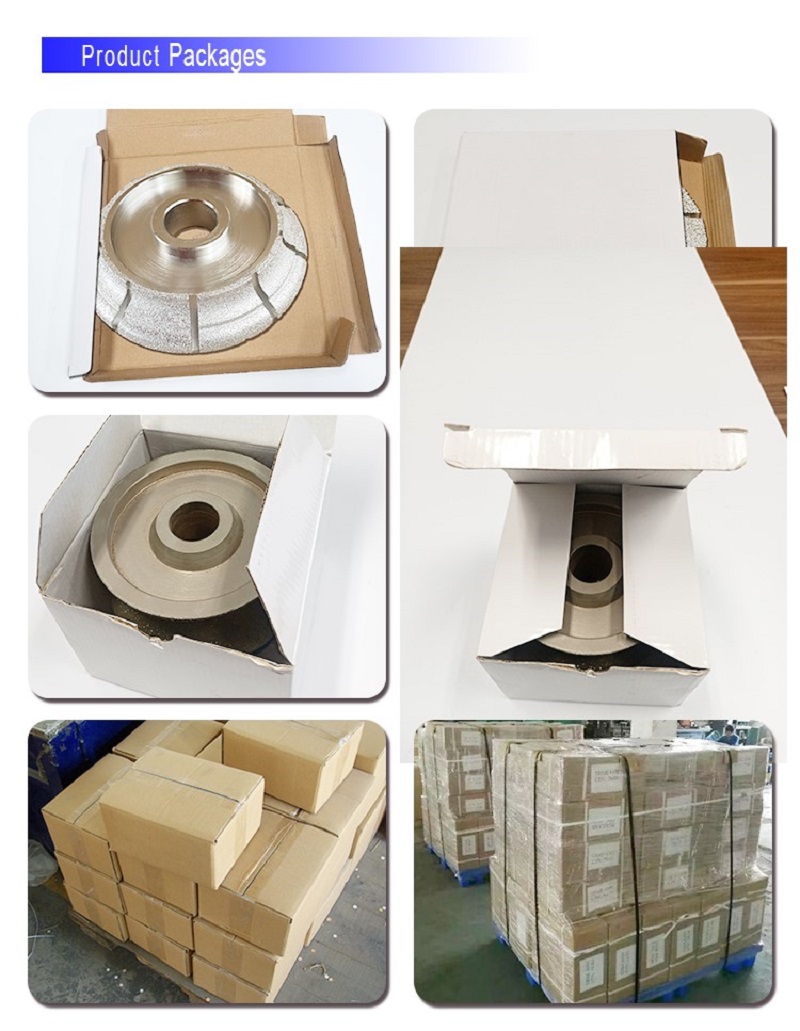

package